Copper strip cover-type furnace annealing technology

An annealing process and a bell-type furnace technology, which are applied in the field of copper strip bell-type furnace annealing process, can solve the problems of large consumption of shielding gas, increase production cost, and optimize the annealing quality of cold-rolled strips, so as to promote the uniformity of grains. The effect of growing, improving production efficiency, internal crystallization quality and crystallization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

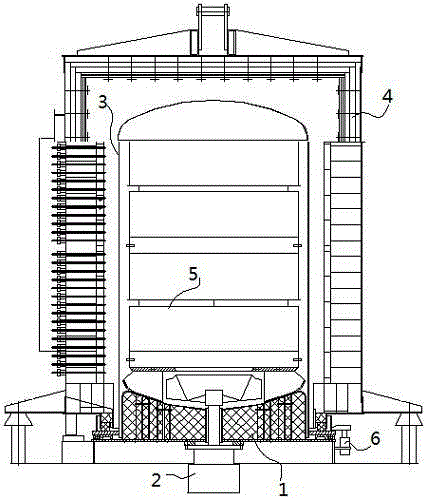

[0039] like figure 1 As shown, a kind of copper strip bell furnace annealing process of the present embodiment comprises the following steps:

[0040] Step 1: sealing and locking of the bell-type furnace;

[0041] The bell-type furnace includes a hearth 1 and an inner cover 3. A fan 2 is arranged at the bottom of the hearth 1, and a support plate is arranged above the hearth 1. A through hole is opened on the support plate, and the blades of the fan 2 are located below the through hole; The copper strip 5 is placed on the support plate, and then the inner cover 3 is covered on the outside of the copper strip 5, and the flange body at the bottom of the inner cover 3 is locked with the stove base 1 to keep the sealing state in the inner cover 3; specifically The flange body at the bottom of the inner cover 3 and the hearth 1 are locked by a hydraulic cylinder 6, and there are eight hydraulic cylinders 6, which are evenly distributed around the hearth 1. The piston rod of the h...

Embodiment 2

[0057] Same as Example 1, the difference is that the heating time of the bell furnace in this example is 4.2h, the heating temperature is 430°C, and the flow rate of the protective gas (that is, the mixed gas of hydrogen and nitrogen) during the heating stage is 9Nm 3 / h; the holding time of the bell-type furnace is 5.2h, and the flow rate of the protective gas during the holding stage is 5.5Nm 3 / h; the air cooling time of the bell furnace cooling stage is 4.2h, the cooling temperature is 280°C, and the protective gas flow rate is 4.5Nm 3 / h, the water cooling time is 5h, the cooling temperature is 70°C, and the protective gas flow rate is 2.5Nm 3 / h.

Embodiment 3

[0059] Same as Example 1, the difference is that the heating time of the bell furnace in this example is 4.5h, the heating temperature is 450°C, and the flow rate of the protective gas (that is, the mixed gas of hydrogen and nitrogen) in the heating stage is 10Nm 3 / h; the holding time of the bell furnace is 5.5h, and the flow rate of the protective gas in the holding stage is 6Nm 3 / h; the air cooling time of the bell furnace cooling stage is 4.5h, the cooling temperature is 300°C, and the protective gas flow rate is 5Nm 3 / h, the water cooling time is 5.5h, the cooling temperature is 80°C, and the protective gas flow rate is 3Nm 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com