Quantum dot light-emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is applied in the manufacturing/processing of organic light-emitting devices, organic light-emitting devices, semiconductor/solid-state device manufacturing, etc. , the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

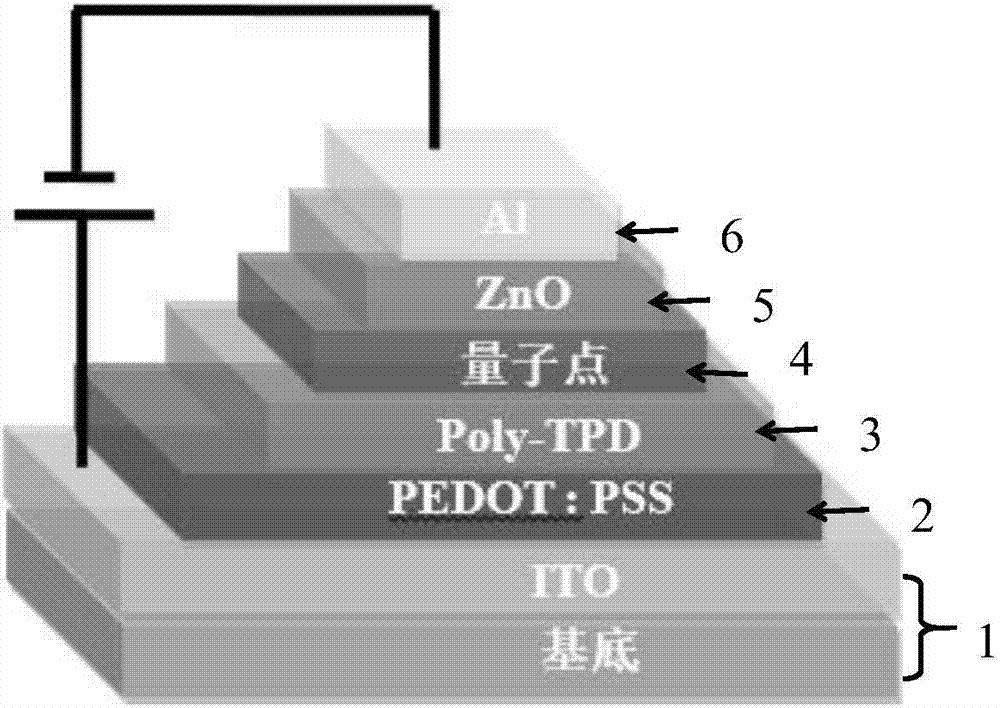

[0026] The invention provides a method for preparing a quantum dot light-emitting diode, comprising the following steps:

[0027] (1) The mixed organic solution comprising polyethylenedioxythiophene and polystyrene sulfonate, the organic solution comprising triphenyldiamine polymer, the organic solution comprising quantum dots and the organic solution comprising zinc oxide are sprayed The ink printing method sequentially prints on the surface of the conductive substrate to obtain the primary quantum dot light-emitting diode;

[0028] The mass ratio of polyethylenedioxythiophene and polystyrenesulfonate to the organic solvent in the mixed organic solution comprising polyethylenedioxythiophene and polystyrenesulfonate is (10-15):100;

[0029] The volume ratio of the total mass of the triphenyldiamine polymer to the organic solvent in the organic solution comprising the triphenyldiamine polymer is (5-10) mg: (1-2) mL;

[0030] The volume ratio of the mass of quantum dots in the ...

Embodiment 1

[0057] Mix Poly-TPD and chlorobenzene at a ratio of 6mg / ml to get Poly-TPD ink; mix quantum dot n-hexane solution at a ratio of 5mg / ml to get quantum dot ink; mix ZnO and ethanol at a ratio of 10mg / ml Prepared to obtain zinc oxide ink; PEDOT:PSS and ethanol are prepared in 12.5% ratio to obtain PEDOT:PSS ink, wherein the mass ratio of PEDOT and PSS is 5:20;

[0058] Fill the obtained PEDOT:PSS ink, Poly-TPD ink, quantum dot ink and zinc oxide ink into the ink cartridge in sequence, and use computer control to perform inkjet printing layer by layer on the surface of ITO conductive glass according to the preset pattern. After inkjet printing, it is left to stand still, and the organic solvent in the ink is volatilized during the static process, and a 0.01mm thick hole injection layer, a 0.01mm hole transport layer, a 0.01mm quantum dot light emitting layer and a 0.01mm electron transport layer are obtained. Quantum dot light-emitting diode; wherein, the volume ratio of the spr...

Embodiment 2

[0061] Mix Poly-TPD and chlorobenzene at a ratio of 6mg / ml to obtain Poly-TPD ink; prepare quantum dot n-hexane solution at a ratio of 15mg / ml to obtain quantum dot ink; prepare ZnO ethanol solution at a ratio of 10mg / ml After mixing, zinc oxide ink is obtained; PEDOT:PSS and ethanol are mixed according to a ratio of 12.5%, to obtain PEDOT:PSS ink, wherein the mass ratio of PEDOT and PSS is 5:20.

[0062]Fill the obtained PEDOT:PSS ink, Poly-TPD ink, quantum dot ink and zinc oxide ink into the ink cartridge in sequence, and use computer control to perform inkjet printing layer by layer on the surface of ITO conductive glass according to the preset pattern. After inkjet printing, it is left to stand still, and the organic solvent in the ink is volatilized during the static process, and a 0.02mm thick hole injection layer, a 0.02mm hole transport layer, a 0.02mm quantum dot light emitting layer and a 0.02mm electron transport layer are obtained. Quantum dot light-emitting diode;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com