Turbulence device for postcombustion chamber of hybrid rocket engine

A technology of engine and afterburner, which is applied in the field of spoiler device for afterburner of solid-liquid rocket engine, can solve the problems of increasing the difficulty of charge, changing the design form of the charge, etc., and achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

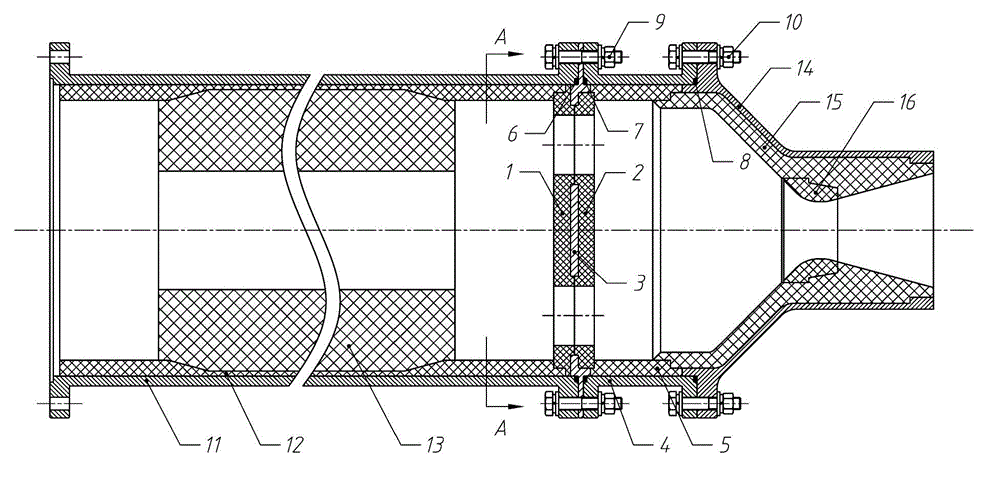

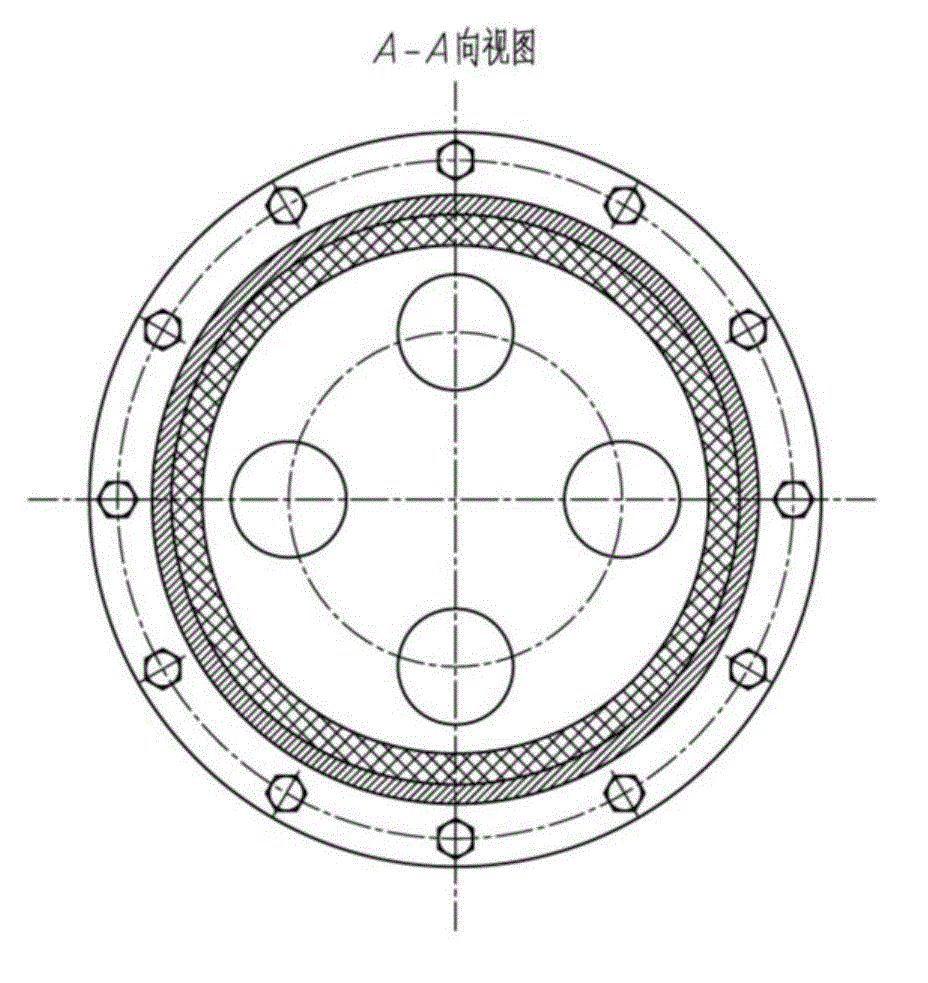

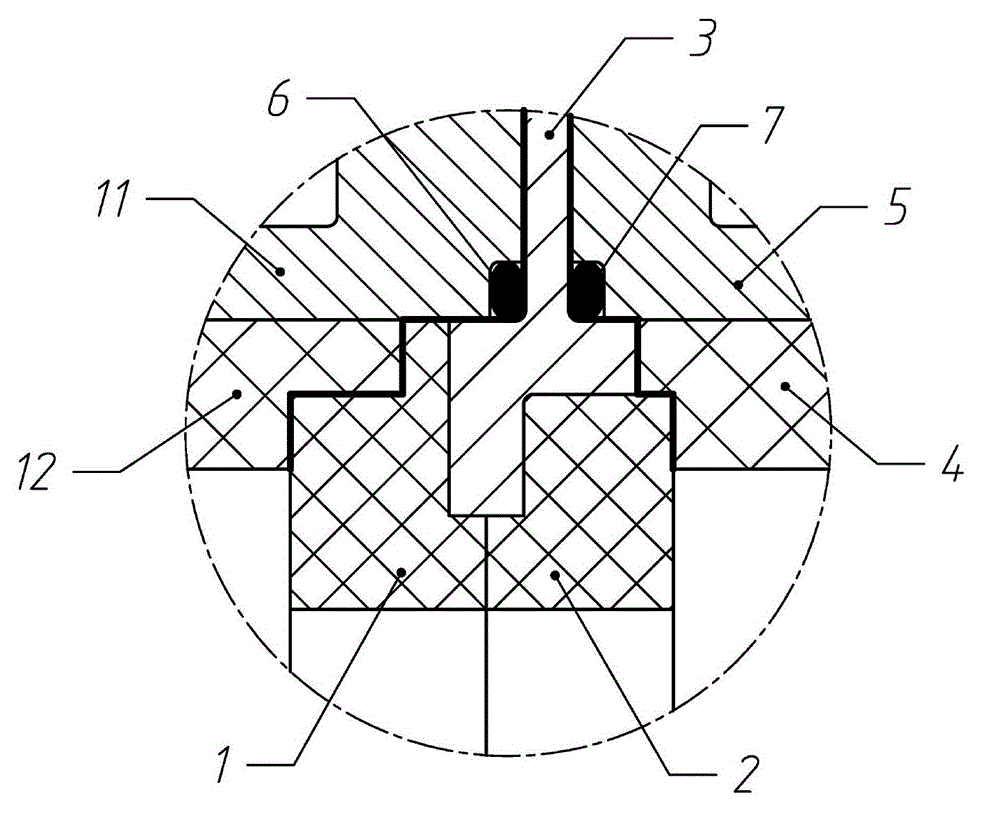

[0011] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the spoiler device for the afterburner of the solid-liquid rocket engine provided by the present invention mainly includes the following components: a heat insulating layer 1 at the front of the spoiler, a heat insulating layer 2 at the rear of the spoiler, a metal frame 3 of the spoiler, and a rear part of the spoiler Combustion chamber housing 4, spoiler rear combustion chamber insulation layer 5, O-ring A6, O-ring B7, O-ring C8, bolt assembly A9, bolt assembly B10, combustion chamber housing 11, combustion chamber Heat insulation layer 12, engine charge 13, nozzle casing 14, nozzle heat insulation layer 15, nozzle throat liner 16.

[0013] Combustion chamber casing 11 and its internal combustion chamber insulation layer 12 and engine charge 13 form a combustion chamber assembly. Combustion chamber insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com