Low-alloy high-strength structural-steel extra-thick board Q460C and production method thereof

A low-alloy, high-strength, production method technology, applied in the field of steel production, can solve the problems of low guarantee of flaw detection, single heavy, thick specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

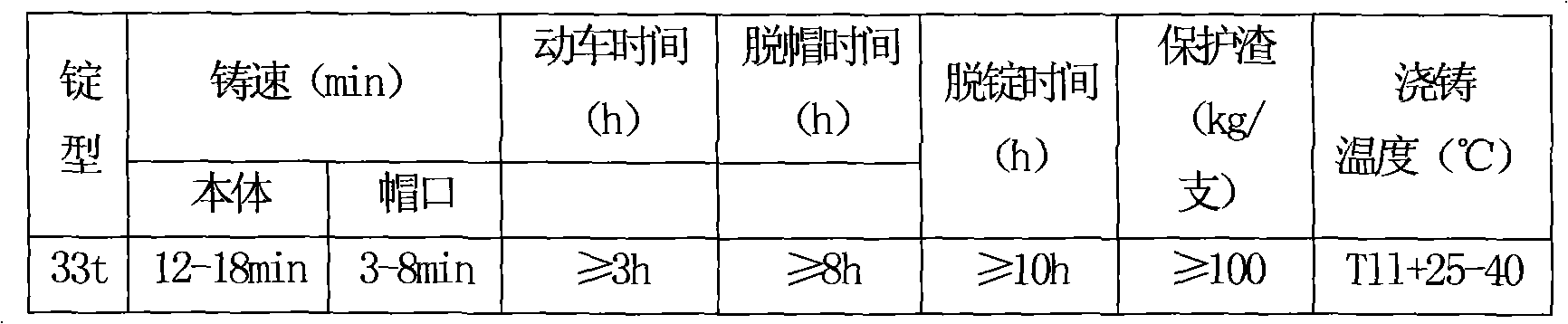

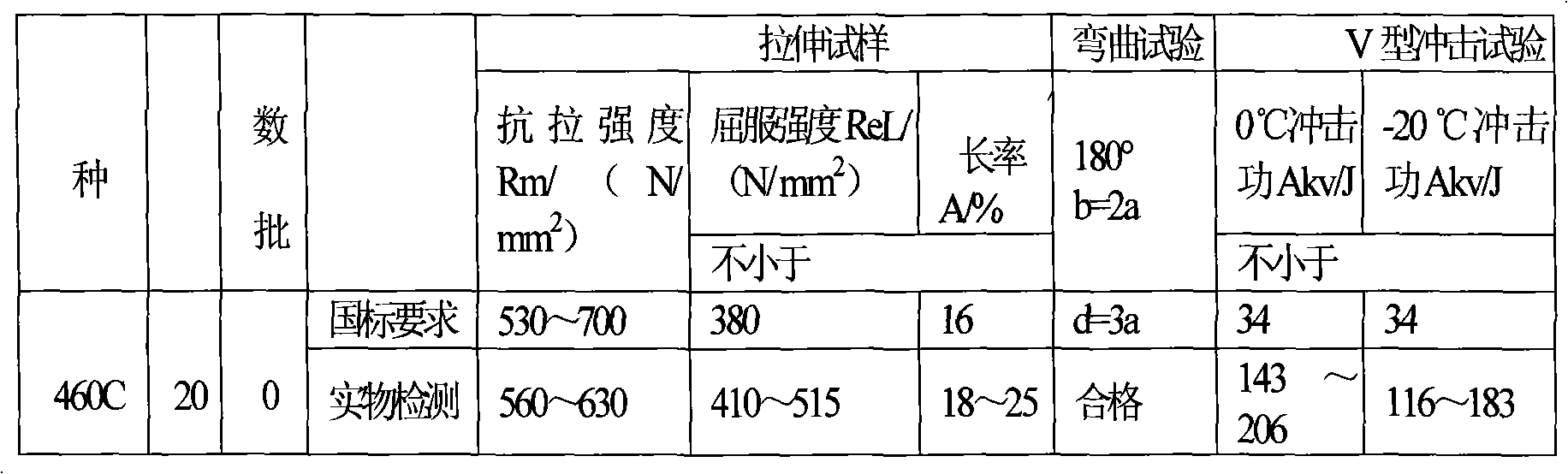

[0022] Through KR desulfurization of molten iron, converter smelting (argon station), LF refining, VD vacuum degassing (Ca treatment), die casting pouring, ingot heating, descaling, 3800 rolling mill rolling, ACC cooling, straightening, steel plate stack cooling, normalization The pyrothermal treatment process obtains Q460C finished steel with the chemical composition described in Table 1 below, and its process parameters and mechanical properties are shown in Table 3 and 4 below.

[0023] Table 1: Chemical Composition of Steel in Example 1

[0024] C%

Embodiment 2

[0026] Through KR desulfurization of molten iron, converter smelting (argon station), LF refining, VD vacuum degassing (Ca treatment), die casting pouring, ingot heating, descaling, 3800 rolling mill rolling, ACC cooling, straightening, steel plate stack cooling, normalization The pyrothermal treatment process obtains Q460C finished steel with the chemical composition described in Table 2 below, and its process parameters and mechanical properties are shown in Table 3 and 4 below.

[0027] Table 2: Chemical composition of steel in Example 2

[0028] C%

Si%

Mn%

P%

S%

Als%

(Nb+Ti+V+Ni)%

0.162

0.34

1.56

0.012

0.003

0.029

0.217

[0029] The process route of the present invention: molten iron KR desulfurization → converter smelting (argon station) → LF refining → VD vacuum degassing (Ca treatment) → mold casting pouring → slow cooling of steel ingots → heating → descaling → 3800 mill rolling → ACC cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com