Multichannel parallel heat release rate test system and test method

A technology of heat release rate and test system, which is applied in the field of multi-channel parallel heat release rate test system, can solve problems such as inability to collect flue gas, inaccurate measurement results, and limited flue gas flow, so as to reduce requirements, reduce load, increase The effect of large total flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

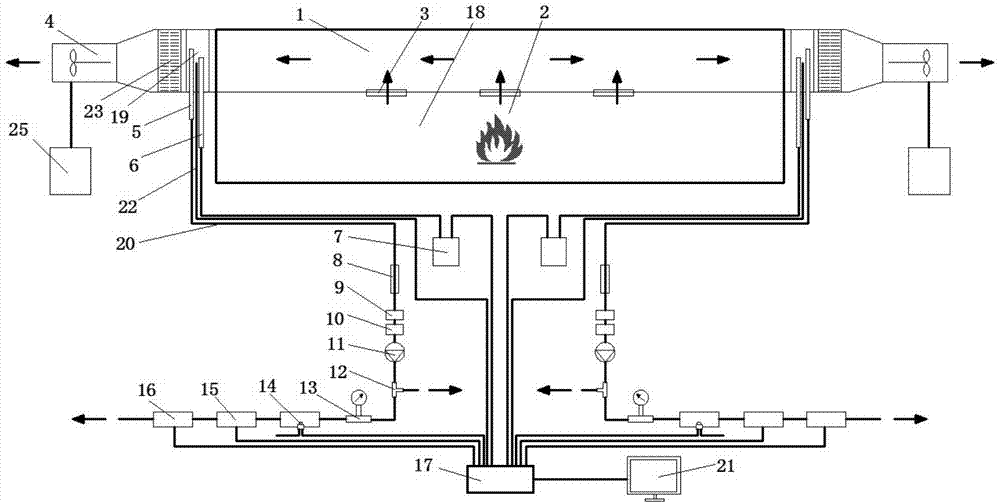

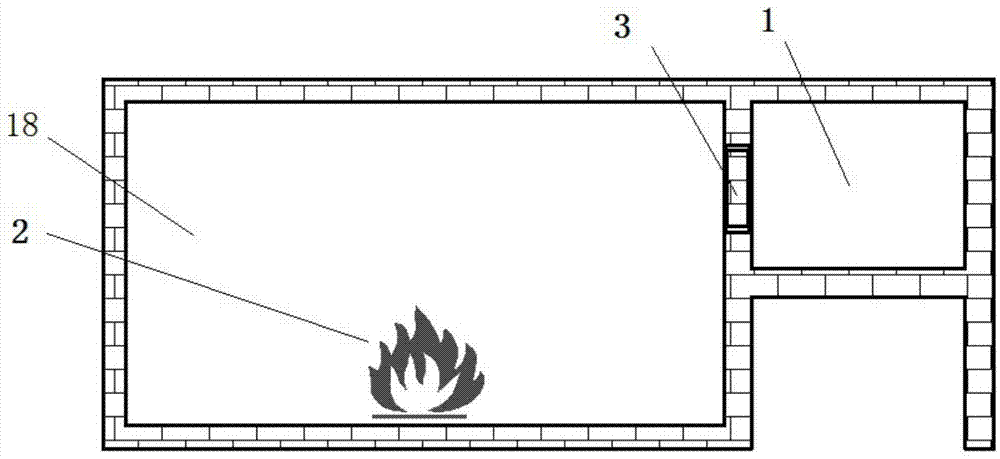

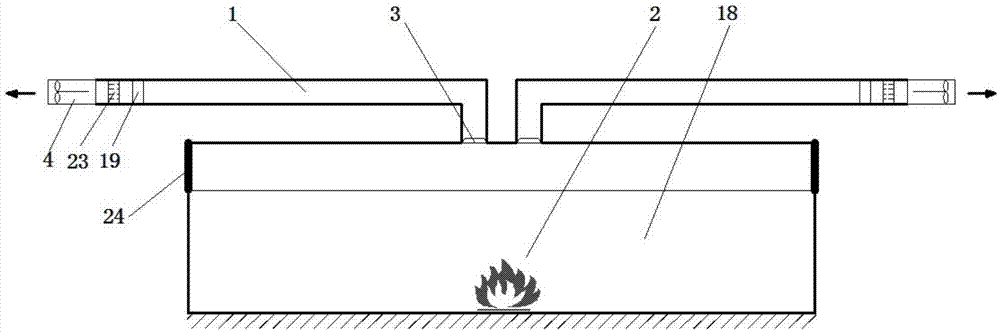

[0054] The schematic diagram of the multi-channel parallel heat release rate testing system of the present invention is as figure 1 As shown, a combustion chamber 18, a data collector 17, a data processor 21 and a plurality of test units are included. ; Combustibles 2 are placed in the combustion chamber 18 ; Each of the test units includes a flue gas collection system, a flue gas flow measurement system and a flue gas sampling system. The smoke collection system includes a smoke exhaust pipe 1, a rectifying grid 23, a sampling section 19 and a smoke exhaust fan 4; the smoke flow measurement system includes a bidirectional pitot tube 6, a differential pressure sensor 7 and a thermocouple 22; the smoke The gas sampling system includes a flue gas sampling pipe 5, a condenser 8, a flue gas filter 9, a drying device 10, a sampling pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com