Building energy-saving wall enclosure OSB cladding structure insulation board

A technology for structural thermal insulation boards and building energy conservation, which is applied in building components, building structures, buildings, etc., can solve the problems of unfavorable mass production and rapid installation, difficult to promote market applications, and few market applications, and avoid the decline of thermal insulation capacity. The effect of increasing water repellency and moisture resistance and good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

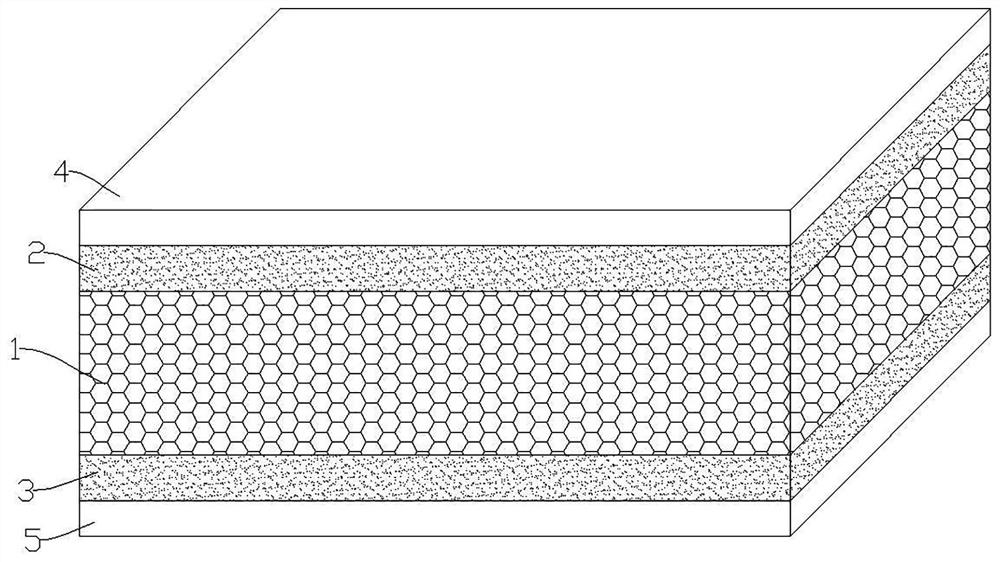

[0028] A building energy-saving wall enclosure OSB cladding structure insulation board, such as figure 1 As shown, it includes an XPS core board 1, an upper board 4 arranged on one side of the XPS core board 1, and a lower board 5 arranged on the other side of the XPS core board 1, the XPS core board 1 and the upper board 4 is provided with an upper cladding panel 2, and a lower cladding panel 3 is provided between the XPS core board 1 and the lower panel 5; the upper cladding panel 2 and the lower cladding panel 3 are OSB boards, and the upper cladding panel 3 is an OSB board. The surface board 4 and the lower table board 5 are light calcium silicate boards; the boards are bonded by one-component reactive polyurethane glue.

[0029] In this embodiment, the performance parameters of XPS core board 1 are as follows: thickness 80mm, density 32 kg / m 3 , thermal conductivity 0.028W / (m•k), compressive strength 350Kpa, water absorption 1%, dimensional stability 1.5%, combustion gra...

Embodiment 2

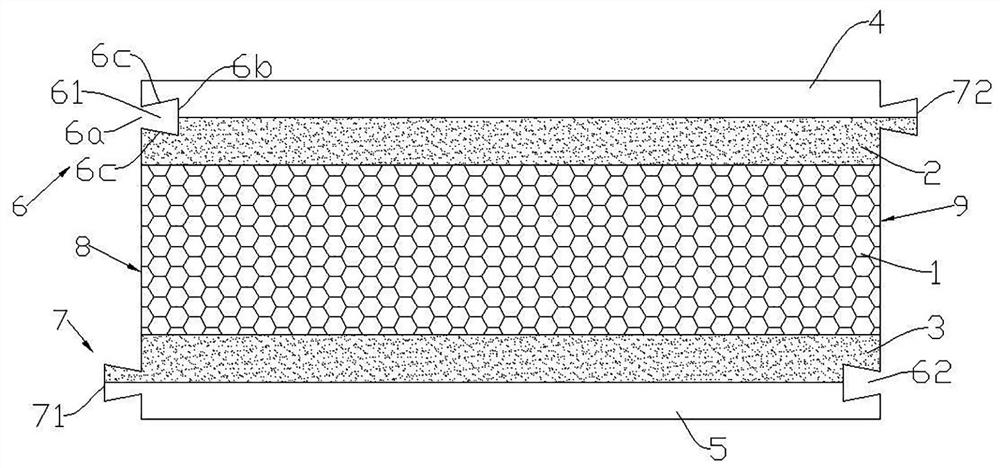

[0033] A building energy-saving wall enclosure OSB cladding structure insulation board, the basic structure is the same as embodiment 1, such as figure 2 As shown, the difference is that this embodiment is also provided with an installation structure that is matched by a connecting piece and a corresponding piece, and the heat preservation board has a first side 8 and a second side 9 opposite to the first side 8; A first connector is provided at a first position of the side 8, a second connector is provided at a second position of the first side 8; a third position corresponding to the first position of the second side 9 A first corresponding piece that can cooperate with the first connecting piece is provided, and a second corresponding piece that can cooperate with the second connecting piece is provided at the fourth position of the second side 9 corresponding to the second position. The first connecting part is the tenon groove 6 or the tenon head 7 , and the second conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com