Connecting method for metal plate, liquid crystal display protective cover and producing method thereof

A liquid crystal display and bonding method technology, which is applied in the direction of instruments, identification devices, nonlinear optics, etc., can solve the problems of light leakage in mechanical bonding parts, and achieve the effects of reducing material costs, excellent electrical conductivity, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

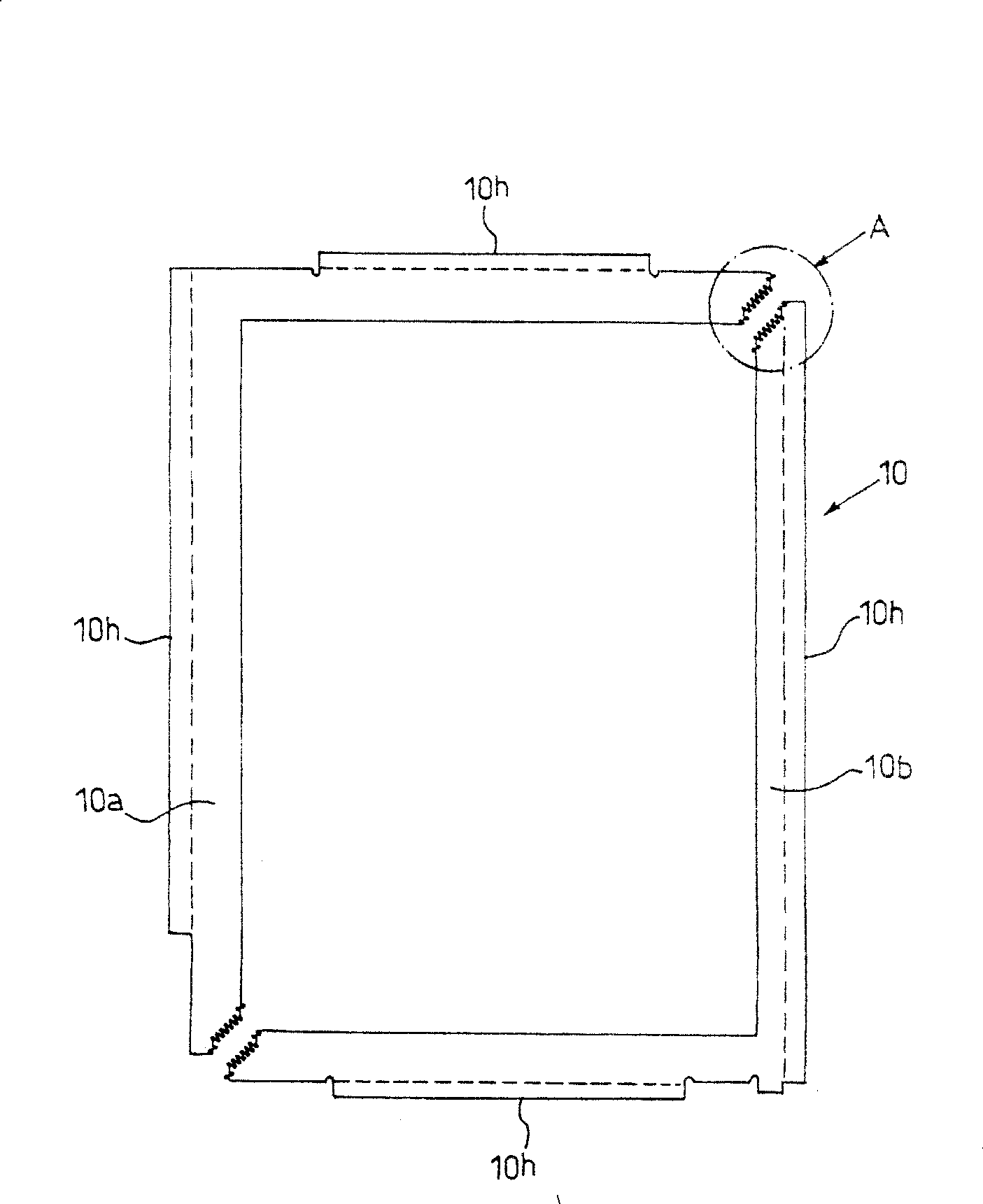

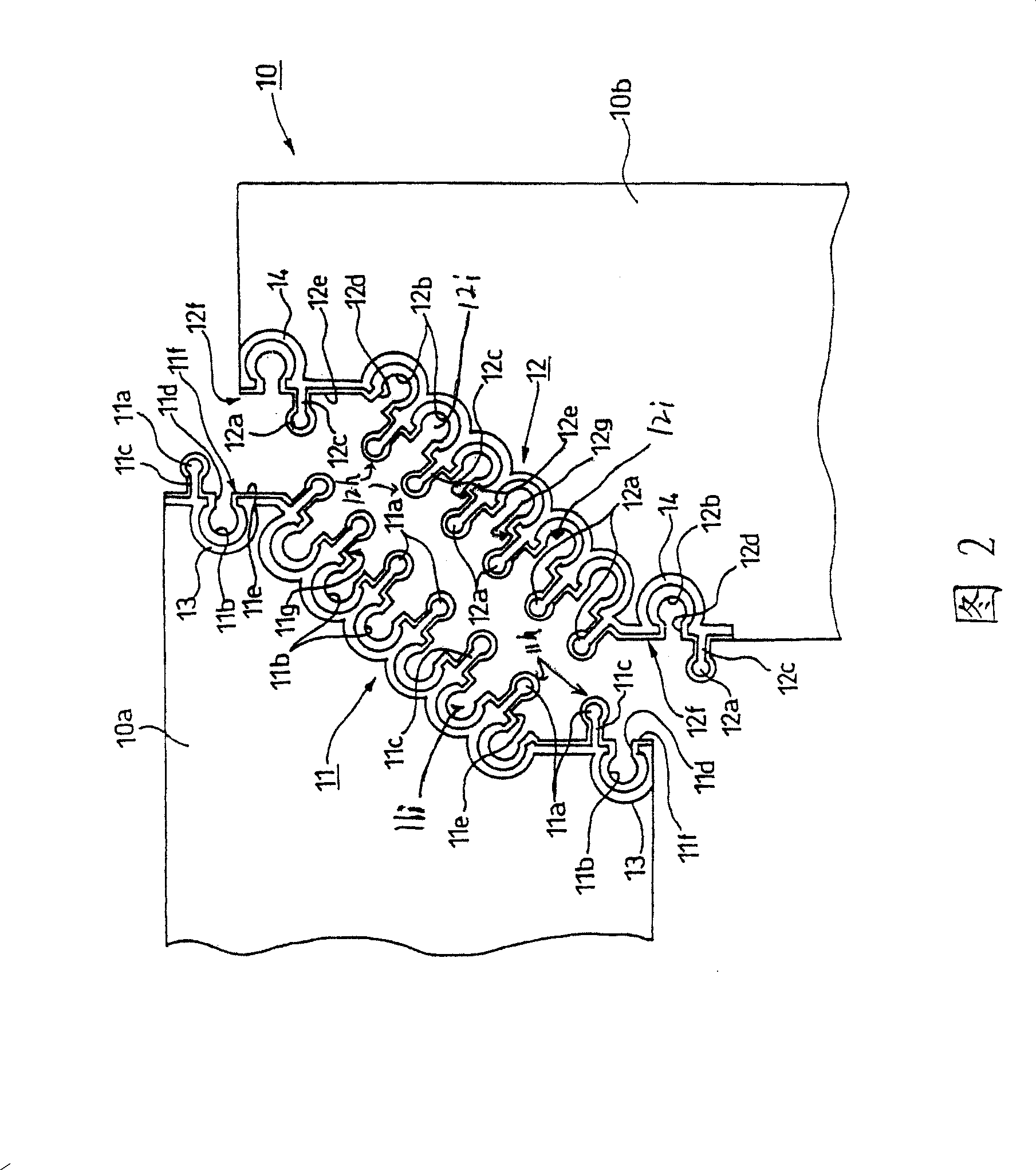

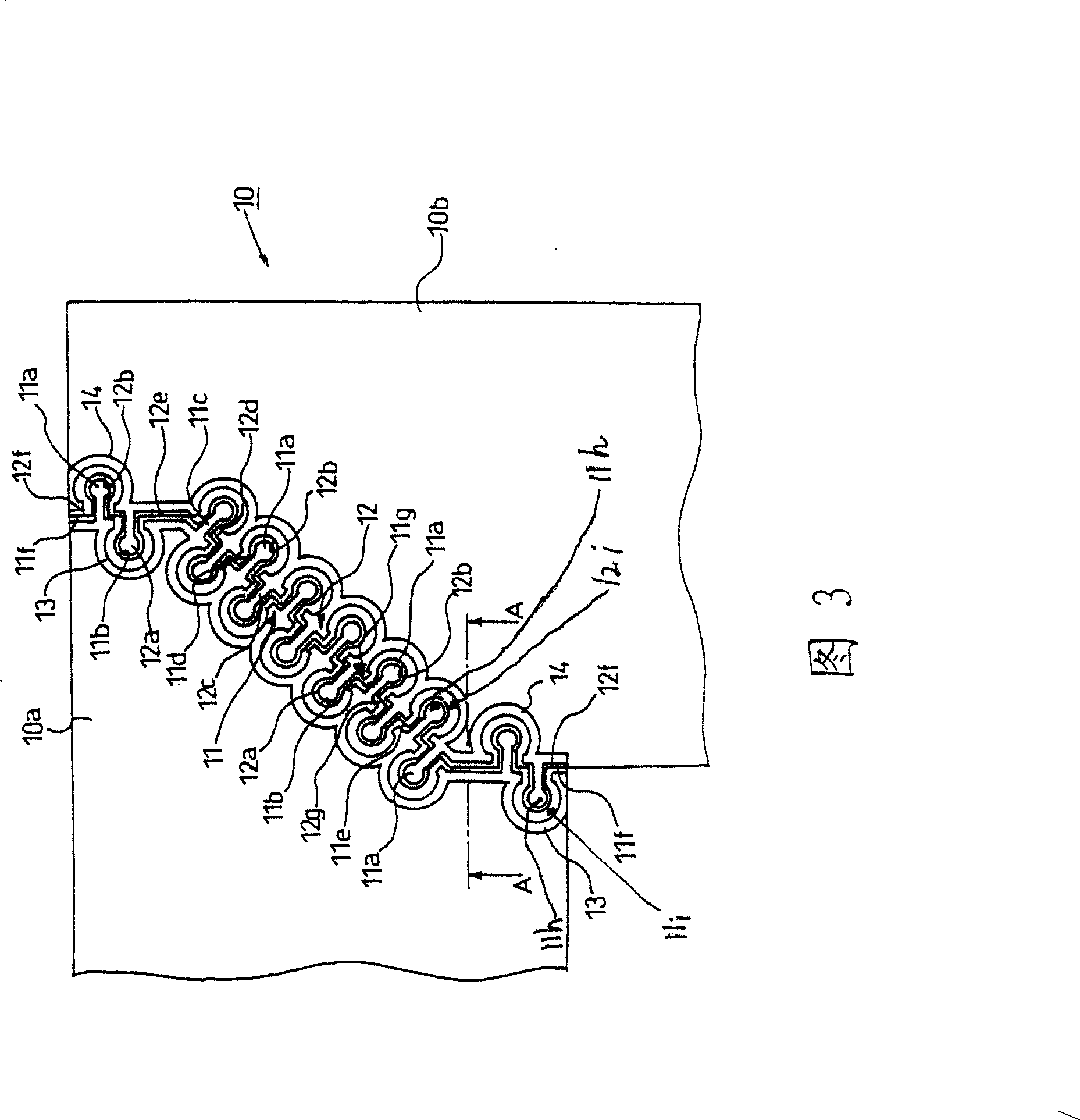

[0085] Figure 1 to Figure 7 An embodiment when the present invention is applied to an intermediate plate of a frame for a liquid crystal display cover is shown. It can be seen from the figure that in figure 1 When the structural members 10a, 10b constituting the following rectangular frame-shaped intermediate plate 10 are combined to form a frame, they are divided into two parts that are approximately L-shaped at the diagonal positions forming the corners. Each end portion of each end, especially as shown in Fig. 2 to Fig. 3, is provided with the fitting locking part that is constituted by the protruding part 11a, 12a that is approximately stud-shaped in planar shape and the recessed part 11b, 12b that is approximately stud-shaped 11, 12. Additionally, especially if figure 1 As shown, the parts that protrude to the outside of each side or are divided by dotted lines are as follows Figure 6 to Figure 7 The shown bending portion 10h when the cross section is bent into an...

Embodiment 2

[0133] Figure 14 In other embodiments, when a part of the intermediate plate 25 is in contact with the storage battery not shown in the figure, only the part in contact with the storage battery is made of gold, copper or a gold-plated conductive connection material 26. The embodiment 2 indicates that the fitting and locking portions 27 and 28 are in the form of straight lines, but a structure other than the structure of the fitting and locking portions shown in Embodiment 1 may also be used. In addition, the mark 26a is a contact part which contacts the storage battery which is not shown in a figure.

[0134] In the above embodiments, the case of implementing on the middle board has been described, but it can also be directly applied to the front board. According to needs, the present invention may be applied only to the middle board, or may be applied to both the middle board and the front board. When it is applied to both places, when it is divided into two places, the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com