Preparation process of zinc oxide coated silicon negative electrode material

A technology of negative electrode material and preparation process, which is applied in the field of preparation technology of zinc oxide-coated silicon negative electrode material, can solve the problems of battery cycle stability and the influence of battery capacity, shedding, fragmentation and pulverization, etc., so as to improve stability and cycle time. Efficiency, increasing electrical contact area, effect of stabilizing surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

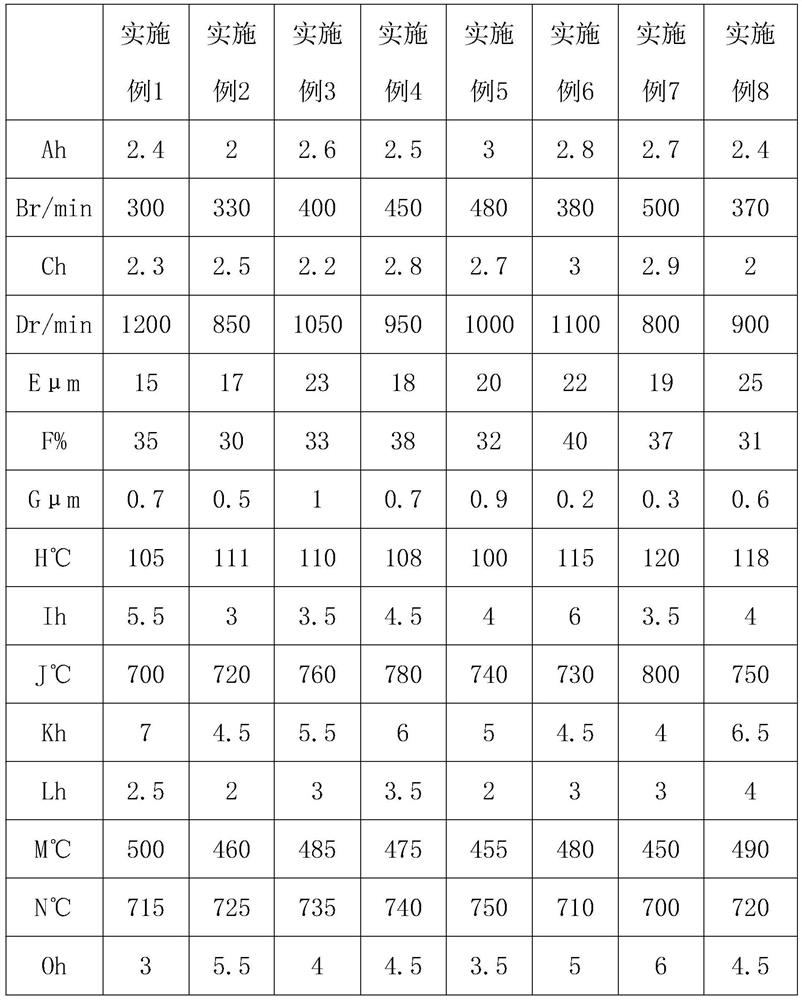

Embodiment 1-8

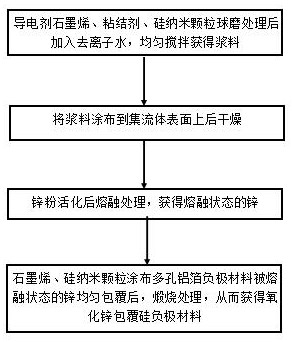

[0027] A preparation process for a zinc oxide-coated silicon negative electrode material, comprising the following steps in sequence:

[0028] 1) Add the conductive agent graphene, binder, and silicon nanoparticles into the ball mill according to the mass ratio of 2:3:15, pass in argon inert gas, and perform ball milling treatment under the protection of argon. After the ball milling is completed, put It is added into a vacuum mixer, and deionized water is injected into the mixer for stirring treatment, so as to obtain a uniformly dispersed slurry;

[0029] 2) Coat the uniformly dispersed slurry prepared in step 1) on the surface of the current collector to form a slurry with a certain coating thickness on the surface of the current collector. The current collector is a porous aluminum foil, and place the uniformly coated aluminum foil on the In a vacuum drying oven, drying treatment, so as to obtain graphene, silicon nanoparticles coated porous aluminum foil anode materials; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com