High-flash-point high-solid-content safe flaky zinc-based zinc-rich coating and preparation method thereof

A zinc-based zinc-rich, flake-like technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of easy damage and cracking of the surface layer, and achieve low VOC content, reduced construction costs, and simple production processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

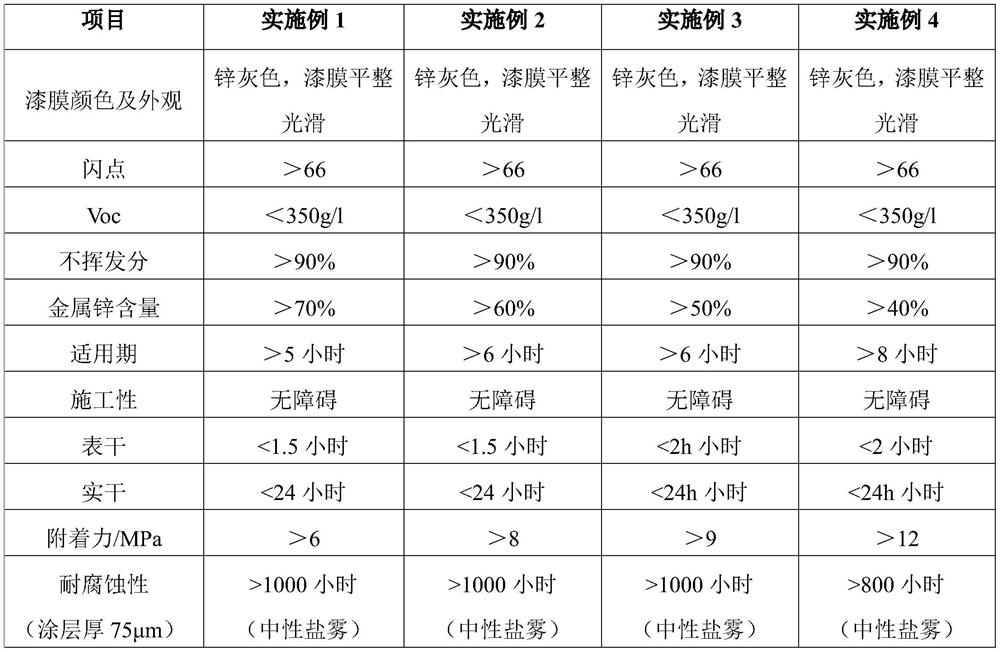

Embodiment 1

[0043] This example provides a high-flash point, high-solid-safe, flaky zinc-based zinc-rich coating, which is made of the following raw materials in terms of mass percentage:

[0044] Low molecular weight epoxy resin, 10wt%;

[0045] Nonylphenol, 2wt%;

[0046] Carbon dodecyl-tetradecyl glycidyl ether, 3wt%;

[0047] Hydrogenated castor oil, 0.8wt%;

[0048] Flake zinc powder, 71wt%;

[0049] Anti-rust pigment JRM, 4wt%;

[0050] Benzyl alcohol, 4.2 wt%;

[0051] Curing agent, 5wt%.

[0052] Further, the curing agent is a modified amine curing agent.

[0053] Further, in terms of mass percentage, the modified ammonium curing agent is made of the following raw materials:

[0054] Benzyl alcohol, 15wt%;

[0055] Isophoronediamine, 15wt%;

[0056] Low molecular weight epoxy resin, 12wt%;

[0057] Polyoxypropylene diamine, 55wt%;

[0058] 2,4,6-tris(dimethylaminomethyl)phenol, 3wt%.

[0059] Further, the model of the low molecular weight epoxy resin is E42.

[0060] ...

Embodiment 2

[0075] This example provides a high flash point and high solid content safe scaly zinc-based zinc-rich coating, which is made from the following raw materials in terms of mass percentage:

[0076] Low molecular weight epoxy resin, 11wt%;

[0077] Nonylphenol, 3wt%;

[0078] Carbon dodecyl-tetradecyl glycidyl ether, 2wt%;

[0079] Hydrogenated castor oil, 0.8wt%;

[0080] Flake zinc powder, 65wt%;

[0081] Anti-rust pigment JRM, 10wt%;

[0082] Benzyl alcohol, 3.2wt%;

[0083] Curing agent, 5wt%.

[0084] Further, the curing agent is a modified amine curing agent.

[0085] Further, in mass percent, the modified ammonium curing agent is made from the following raw materials:

[0086] Benzyl alcohol, 15wt%;

[0087] Isophoronediamine, 18wt%;

[0088] Low molecular weight epoxy resin, 11wt%;

[0089] Polyoxypropylene bisamine, 53.5wt%;

[0090] 2,4,6-Tris(dimethylaminomethyl)phenol, 2.5 wt%.

[0091] Further, the model of the low molecular weight epoxy resin is E44.

...

Embodiment 3

[0107] This example provides a high flash point and high solid content safe scaly zinc-based zinc-rich coating, which is made from the following raw materials in terms of mass percentage:

[0108] Low molecular weight epoxy resin, 12wt%;

[0109] Nonylphenol, 2.2wt%;

[0110] Carbon dodecyl-tetradecyl glycidyl ether, 2wt%;

[0111] Hydrogenated castor oil, 0.7wt%;

[0112] Flake zinc powder, 55wt%;

[0113] Anti-rust pigment JRM, 20wt%;

[0114] Benzyl alcohol, 3.1 wt%;

[0115] Curing agent, 5wt%.

[0116] Further, the curing agent is a modified amine curing agent.

[0117] Further, in mass percent, the modified ammonium curing agent is made from the following raw materials:

[0118] Benzyl alcohol, 15wt%;

[0119] Isophoronediamine, 20wt%;

[0120] Low molecular weight epoxy resin, 10wt%;

[0121] Polyoxypropylene bisamine, 52.6wt%;

[0122] 2,4,6-Tris(dimethylaminomethyl)phenol, 2.4 wt%.

[0123] Further, the model of the low molecular weight epoxy resin is E51....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com