Electric connector and jack contact piece of rotating hyperboloid bus set densely-wound wire spring structure

A technology of jack contacts and electrical connectors, which is applied in the parts, connections, electrical components and other directions of connecting devices, can solve the problem of inability to achieve high current and high power transmission, small contact area between jacks and pins, and probability of instantaneous interruption. Large and other problems, to achieve the effect of high power transmission, reduce the probability of instantaneous interruption, and increase the time of instantaneous interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

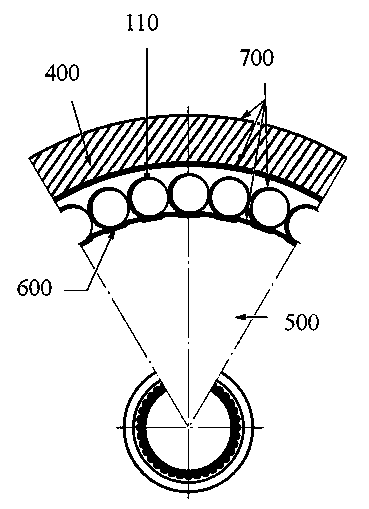

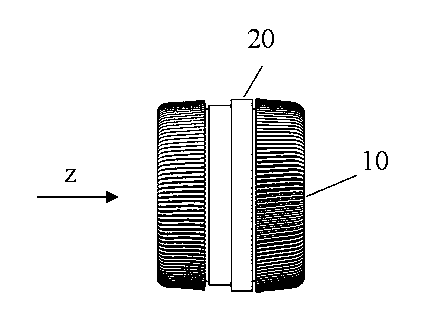

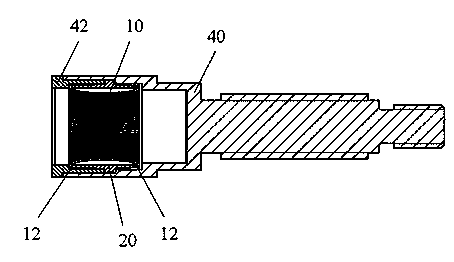

[0032] The following is attached Figure 2~Figure 8 As shown, a new type of electrical connector with a rotating hyperboloid densely wound wire spring structure provided by the present invention is introduced.

[0033] Such as figure 2 The illustrated receptacle contact includes a wire circlip 20 and a rotating hyperboloid densely wound wire spring busbar family 10 . Cooperate see Figure 2~Figure 4 As shown, a group of straight generatrices 11 composed of elastic metal wires (or called metal spring wires) are left-handed or right-handed in the manner of equal slope (or equal "helix angle β"), and are evenly distributed along the circumference to A structure of the rotating hyperboloid densely wound spring generatrix 10 around the z-axis with large ends and a small middle is formed, and the inside of the receptacle contact is formed as a receptacle 41 arranged axially.

[0034] Each straight busbar 11 in the rotating hyperboloid close-wound spring busbar family 10 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com