Superconducting magnet joint and manufacturing method thereof

A technology of superconducting magnets and superconducting joints, applied in superconducting magnets/coils, magnetic objects, superconducting devices, etc., can solve problems such as unsuitable for engineering use, harsh environmental requirements, and cumbersome manufacturing processes, and achieve simple structure , the production and maintenance are large, and the production method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

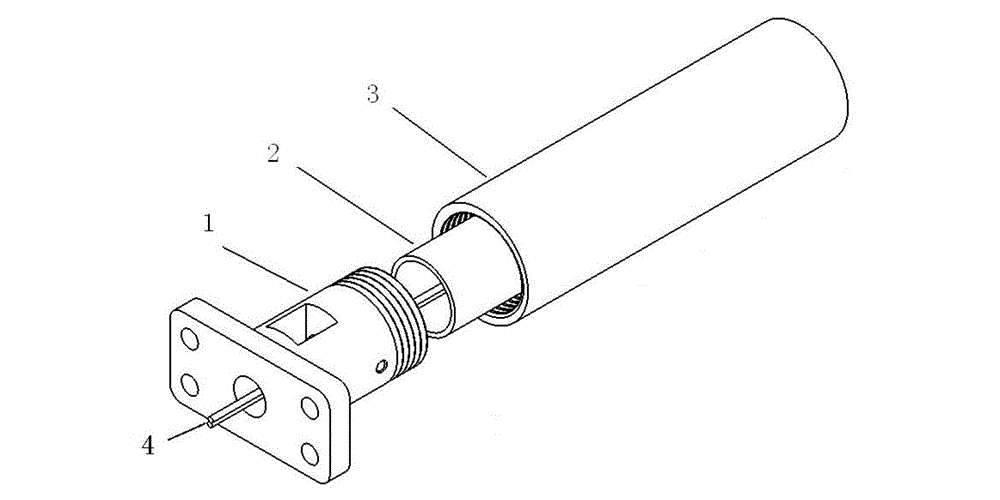

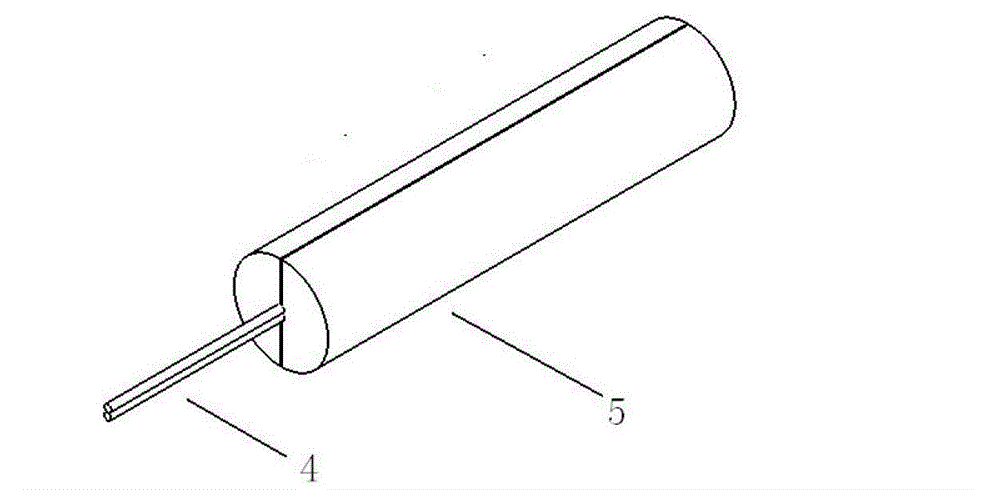

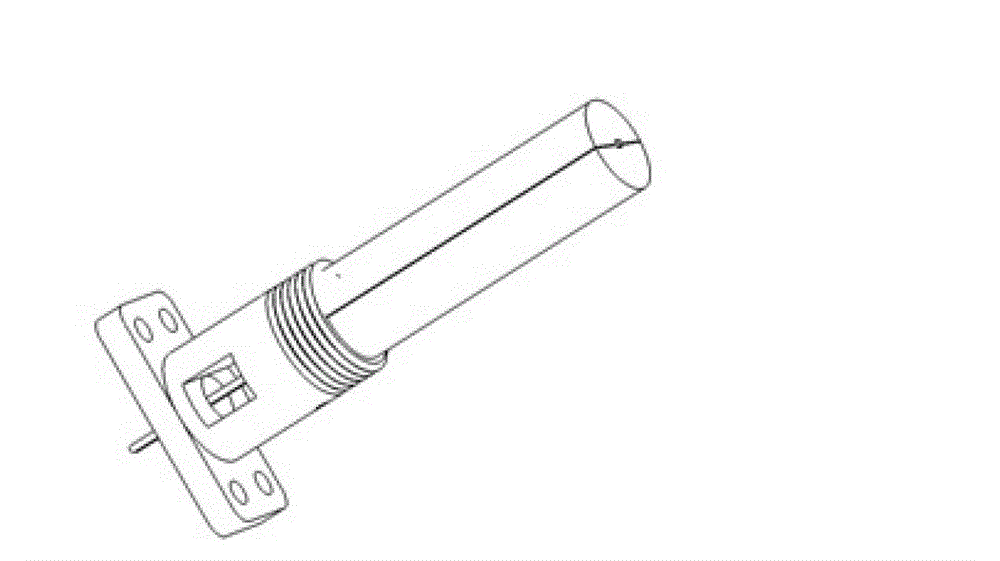

[0031] Embodiment 1, a kind of superconducting magnet joint, refer to figure 1 , including the joint seat 1 fixed on the seat plate and the copper sleeve 2 and the envelope 3 connected thereto, the two superconducting wires 4 are all niobium-three-tin superconducting wires 10 introduced from the lead hole on the end face of the joint seat 1, and welded to be superconducting Joint, between the copper sleeve 2 and the superconducting joint is potted Wood's alloy 7, see Figure 4 , two niobium-three-tin superconducting wires 10 are surrounded by Nb barrier layer 8, lead-bismuth conductor 9, Wood alloy 7 and copper sheath 2; the envelope 3 is connected to the joint seat 1 by threads, and is used to protect the superconducting joint 1 and shield the magnetic field ; In order to ensure high mechanical strength, the joint seat 1 and the envelope 3 are made of stainless steel, and in order to reduce the resistance of the superconducting joint, the copper sleeve 2 is made of oxygen-fre...

Embodiment 2

[0036] Embodiment 2, a kind of superconducting magnet joint, refer to figure 1 , including the joint base 1 fixed on the seat plate and the copper sleeve 2 and the envelope 3 connected thereto; in order to facilitate the production of superconducting joints when the materials of the two superconducting wires are different, the end surface and the side of the joint base 1 are respectively provided with lead holes. In this embodiment, the two superconducting wires 4 are a niobium-three-tin superconducting wire 10 and a niobium-titanium superconducting wire 6, which are respectively introduced and welded into superconducting joints from the lead holes on the end face and side of the joint base 1, see Figure 5 , the niobium-three-tin superconducting wire 10 and the niobium-titanium superconducting wire 6 are surrounded by a Nb barrier layer 8, a lead-bismuth conductor 9, Wood's alloy 7 and a copper sleeve 2; between the copper sleeve 2 and the superconducting joint is potted Wood'...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com