Low-temperature wafer direct bonding machine and wafer bonding method

A direct bonding and wafer bonding technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor debonding and synthesis efficiency, and achieve the goals of avoiding scrapping, improving success rate, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] As mentioned in the background art, the existing debonding technology still has the problem of poor success rate of debonding.

[0038] The study found that although debonding technology can be used to separate pre-bonded wafer pairs, the success rate of separation depends on time (the time between pre-bonding and debonding), and the longer the time, the lower the success rate of debonding (Unless all factors are perfectly controlled, the success rate is <=70%), because the bonding strength between the pre-bonded wafer pair has an absolute relationship with the time of placement, at room temperature, the pre-bonded wafer The bonding strength of the pair will increase rapidly in a short period of time, and the increase in bonding strength will lead to a decrease in the success rate of debonding.

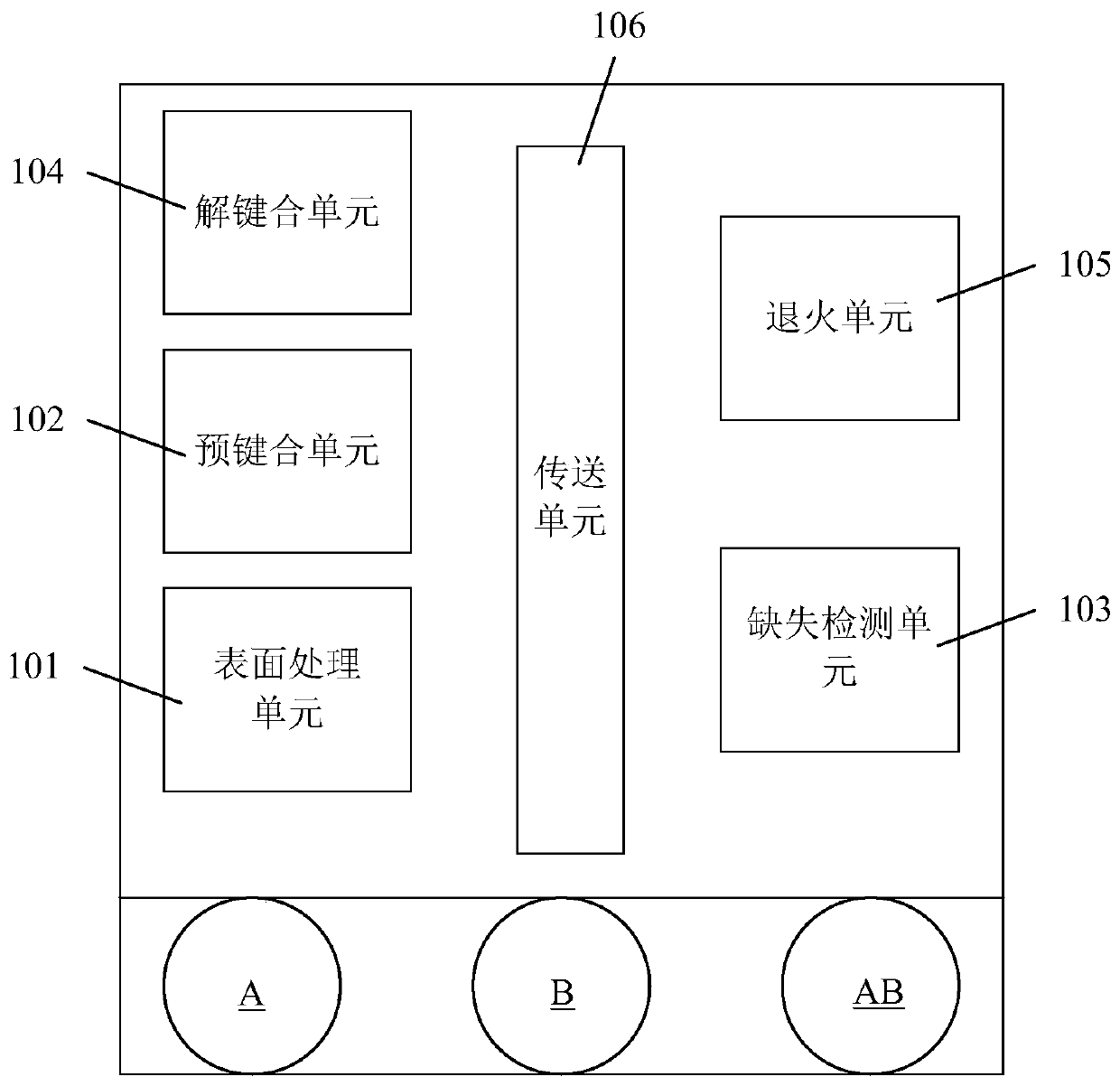

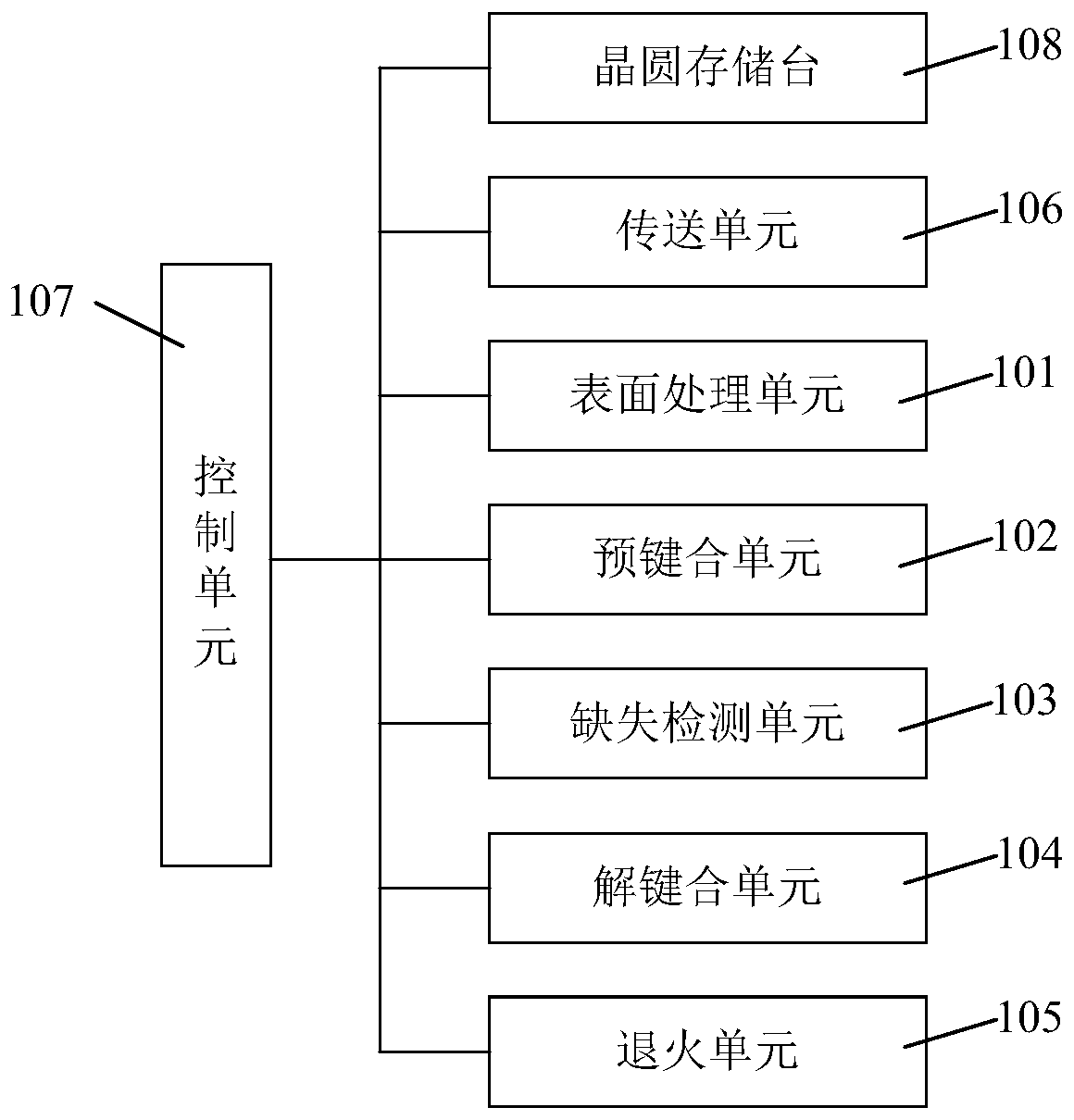

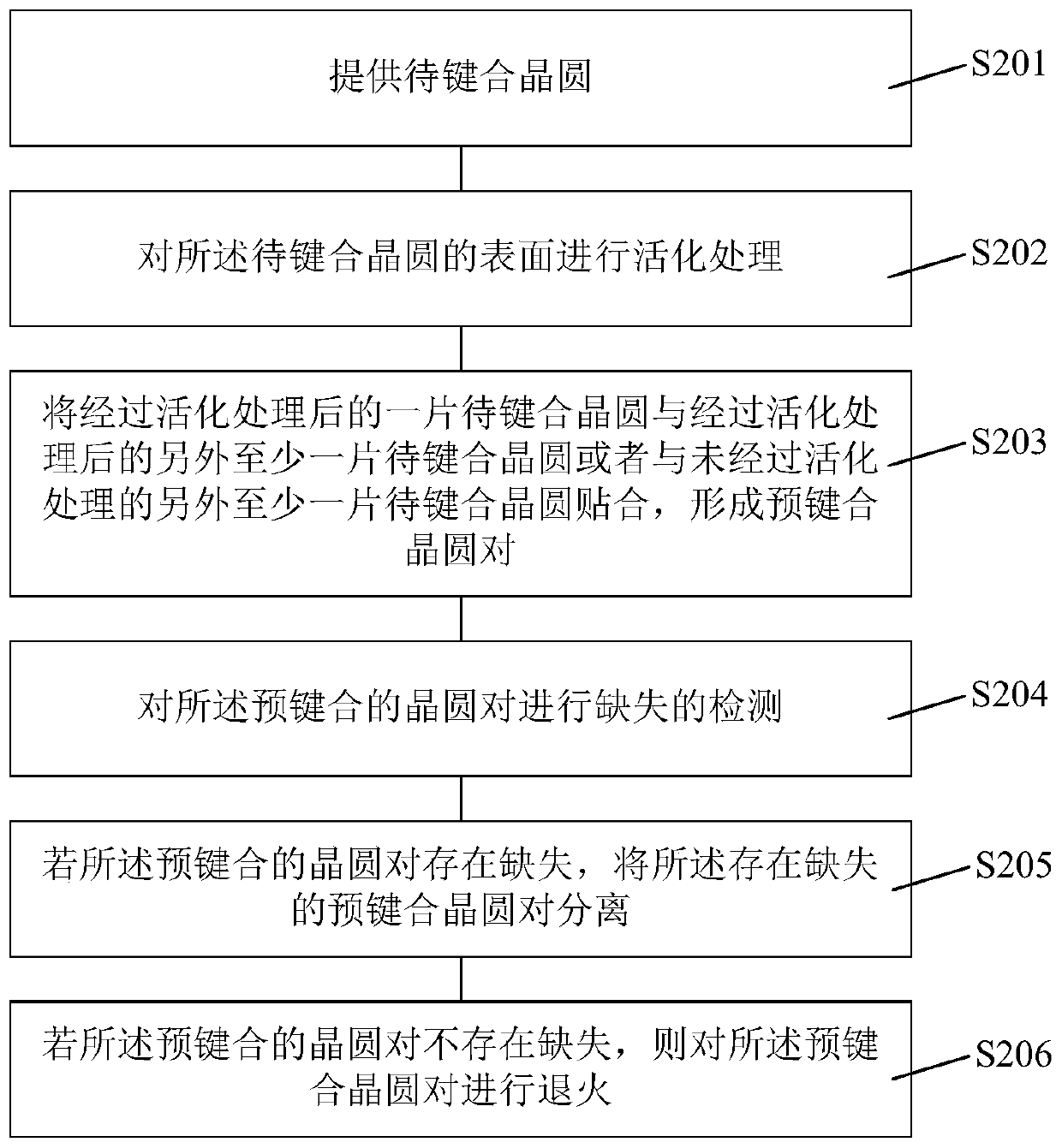

[0039] Moreover, the existing low-temperature wafer bonding generally includes four processes of surface treatment, pre-bonding, missing detection, and annealing. It is carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com