Chip on film, flexible display panel and display device

A chip-on-chip and flexible display technology, which is applied in identification devices, static indicators, semiconductor/solid-state device components, etc., can solve problems such as poor binding between COF and flexible display panels, misalignment of input pads, etc., and achieve improvement Binding yield, avoiding misalignment, and increasing the effect of crimping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

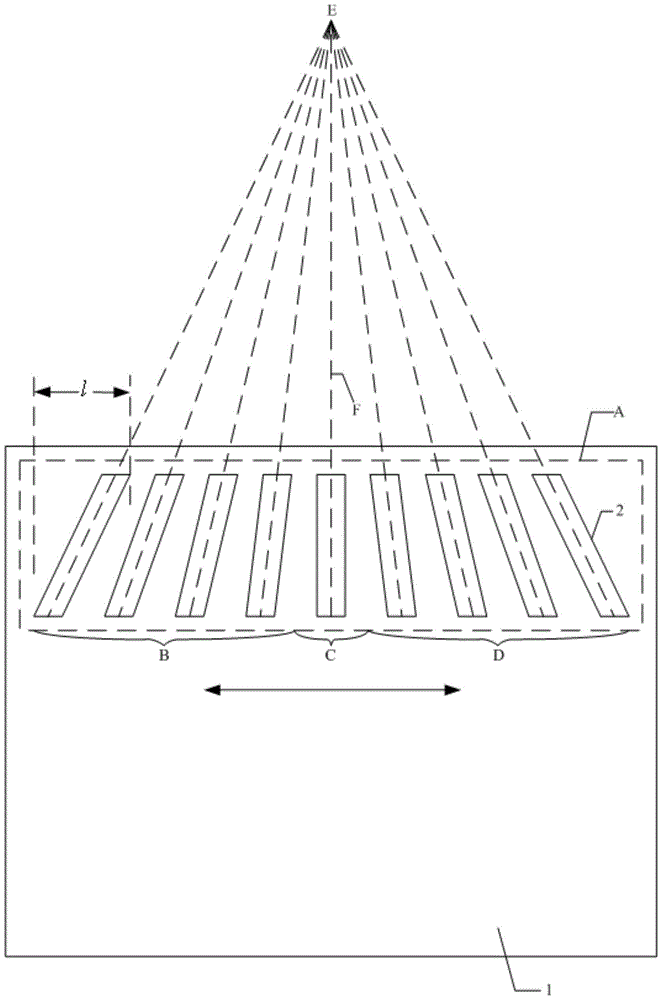

[0056] Example 1: The area where each row of input pads is located is divided into three areas: the first area, the second area and the third area.

[0057] In specific implementation, in the above flexible display panel provided by the embodiment of the present invention, since the second area is located in the center of the area where a row of input pads is located, the first area and the third area are respectively located on both sides of the second area, and the flexible The expansion of the middle area in the binding area of the display panel less than that of the side areas results in a smaller spacing between adjacent input pads in the middle area than in the side areas, so , in order to increase the crimping area between the input pad in the binding area of the flexible display panel and the output pad of the chip-on-chip film, and avoid misalignment between the output pad of the chip-on-film and the input pad in the binding area of the flexible display panel To...

example 2

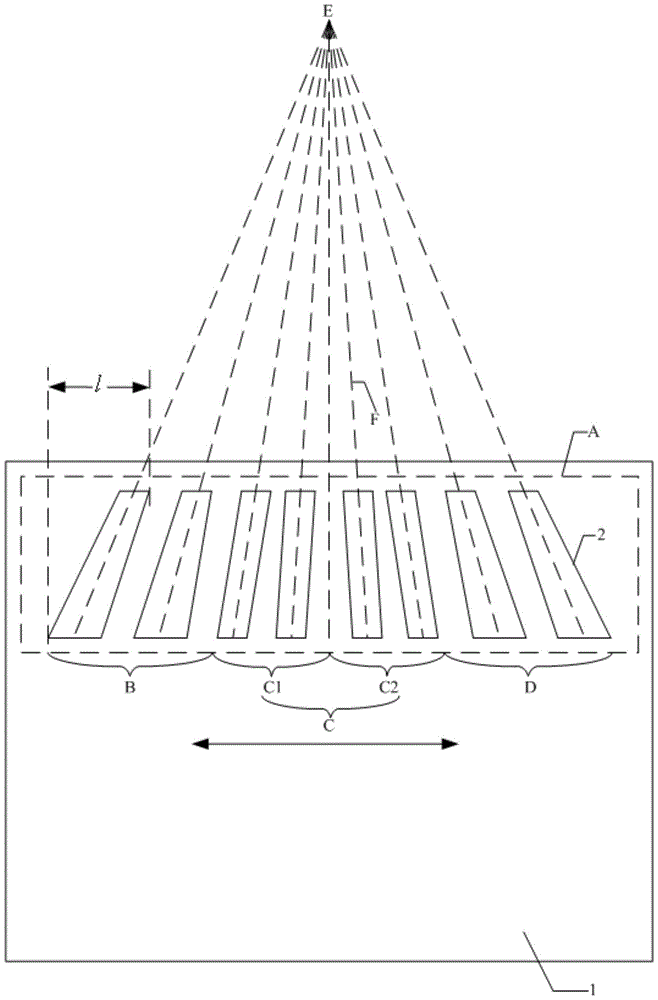

[0060] Example 2: The area where each row of input pads is located is divided into the first area, the second area and the third area, wherein the second area is divided into an even number of sub-areas, and the second area is divided into two sub-areas as an example. The area where each row of input pads is located is divided into four areas.

[0061] In specific implementation, in the above-mentioned flexible display panel provided by the embodiment of the present invention, the second area can be equally divided into M sub-areas, where M is an even number (that is, M=2, 4, 6...), figure 2 Taking the second area C equally divided into the first sub-area C1 and the second sub-area C2 as an example; since the first sub-area C1 and the second sub-area C2 are located in the center of the area where a row of input pads 2 is located, the first area B and the third area D are respectively located on both sides of the first sub-area C1 and the second sub-area C2, and the expansion ...

example 3

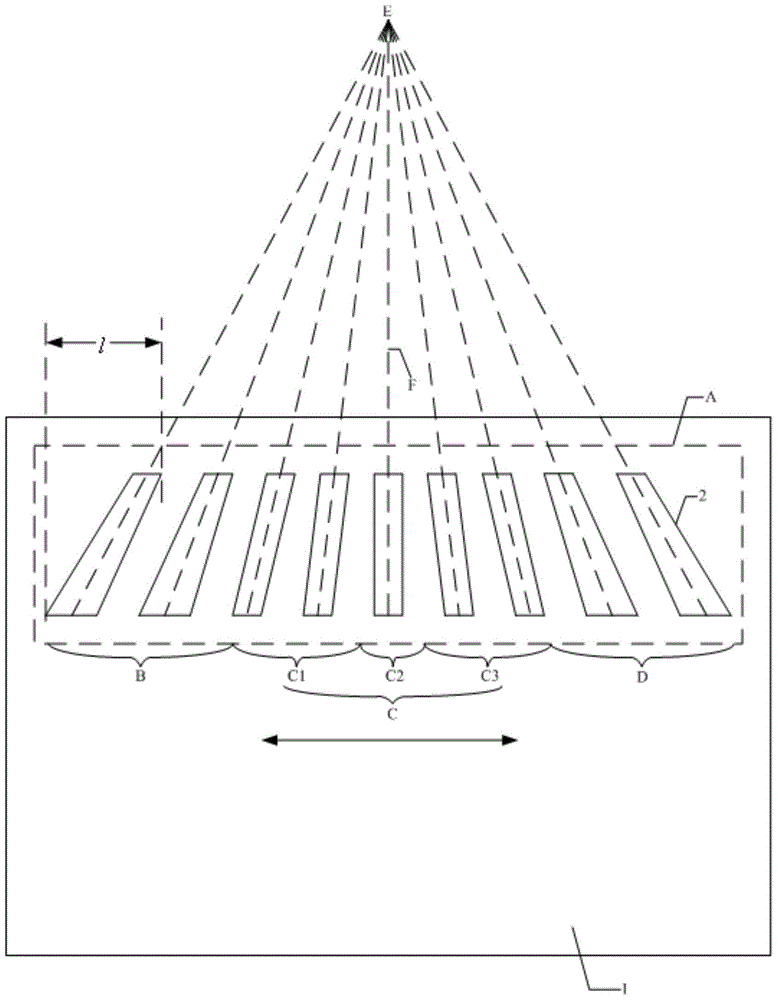

[0064] Example 3: The area where each row of input pads is located is divided into a first area, a second area and a third area, wherein the second area is divided into an odd number of sub-areas greater than 1, and the second area is divided into three sub-areas as For example, the area where each row of input pads is located is divided into five areas.

[0065] In specific implementation, in the above-mentioned flexible display panel provided by the embodiment of the present invention, the second area can be equally divided into N sub-areas, where N is an odd number greater than 1 (that is, N=3, 5, 7...), image 3 Taking the second area C equally divided into the first sub-area C1, the second sub-area C2 and the third sub-area C3 as an example; since the second sub-area C2 is located in the center of the second area C, the second area C is located at a The center of the area where a row of input pads 2 is located, that is, the second sub-area C2 is located in the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com