Polaroid, display module, touch control type display device, and manufacturing method thereof

A technology of a display module and a display device is applied in the field of polarizers to achieve the effects of improving the bonding yield, smoothing the light-emitting surface, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the above-mentioned objects, features, and advantages of the present invention more apparent, a detailed description will be given below in conjunction with the accompanying drawings.

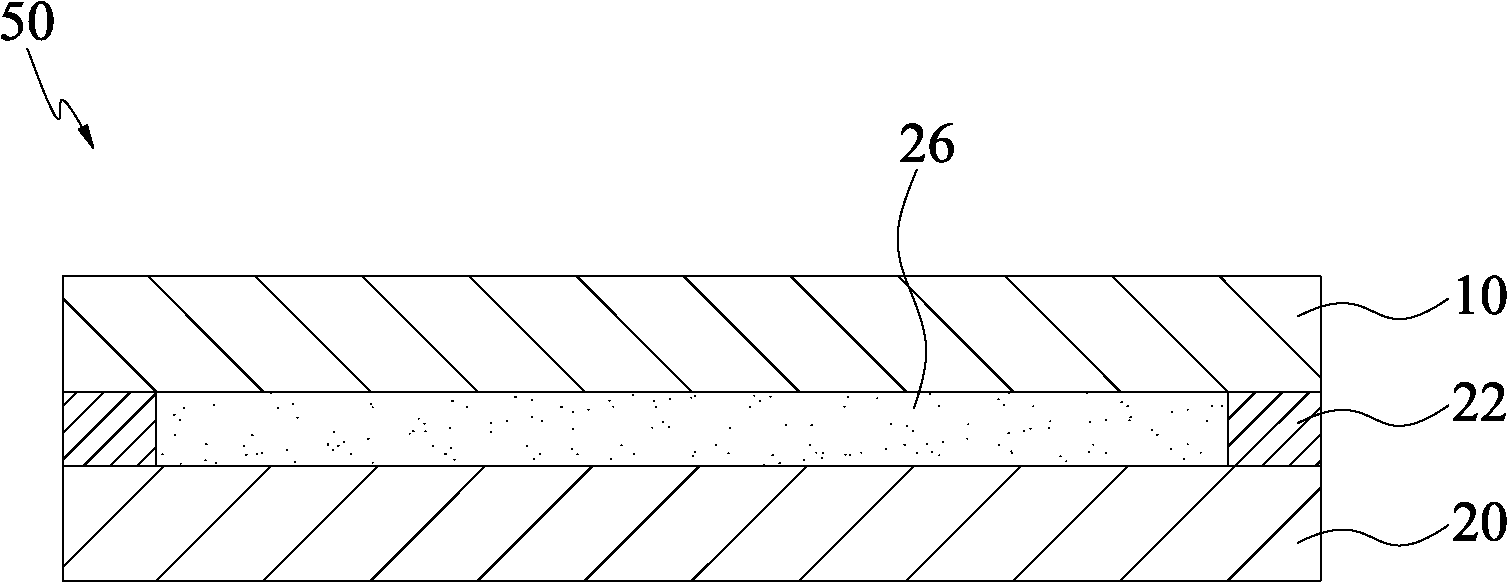

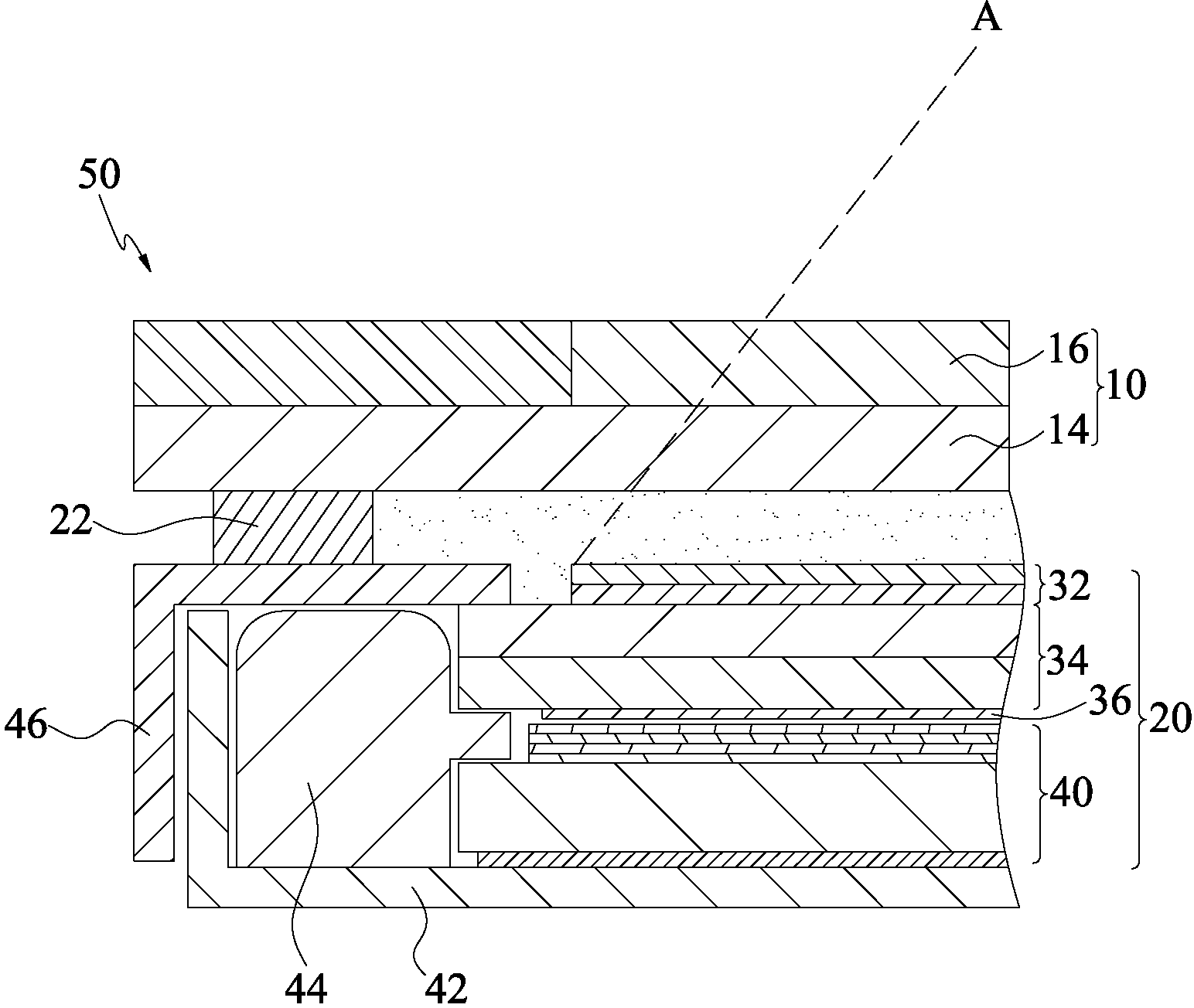

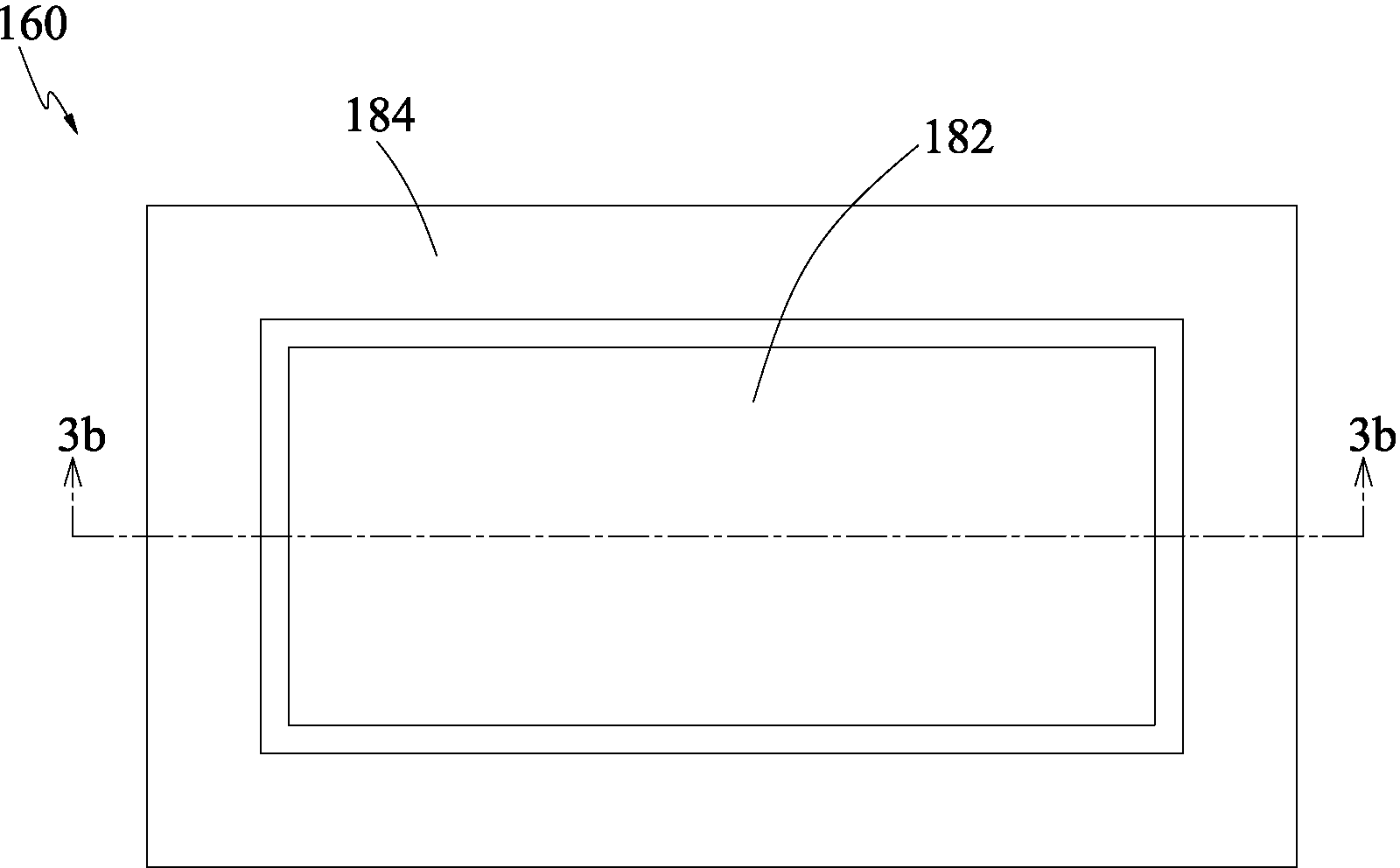

[0066] Please refer to Figure 3a and Figure 3b , which shows the structure of the polarizer 160 of the first embodiment of the present invention. The polarizer 160 includes a release film 162 , an adhesive layer 164 and a polarizing substrate layer 166 . For example, the polarizing substrate layer may include a polyvinyl alcohol (PVA) body layer, a triacetyl cellulose (TAC) support film and a protective film.

[0067] The adhesive layer 164 is disposed on a surface 166a of the polarizing substrate layer 166, and includes a middle region 182 and a peripheral region 184, the middle region 182 is separated from the peripheral region 184, wherein the middle region 182 of the glue layer 164 is an optical The adhesive layer 164 of the peripheral area 184 can be optically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com