Liquid crystal display and method for restoring broken wires

A liquid crystal display and grid line technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as waste and increase production costs, and achieve the effects of avoiding waste, saving production costs, and avoiding product waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

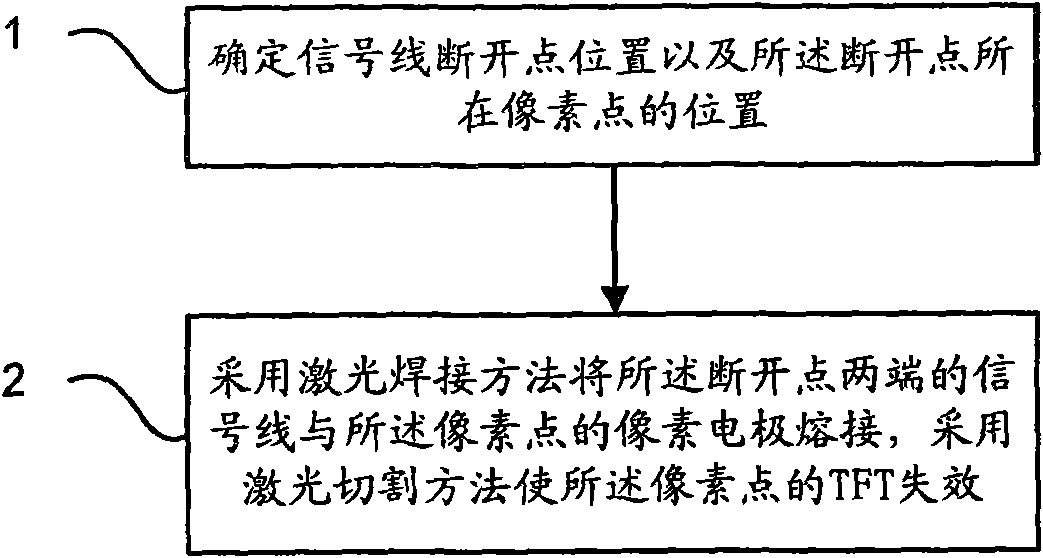

[0033] figure 1 It is a flow chart of the method for repairing a broken line of a liquid crystal display of the present invention, specifically including:

[0034] Step 1. Determine the position of the disconnection point of the signal line and the position of the pixel where the disconnection point is located;

[0035] Step 2. Laser welding is used to weld the signal lines at both ends of the disconnection point to the pixel electrode of the pixel, and laser cutting is used to disable the TFT of the pixel.

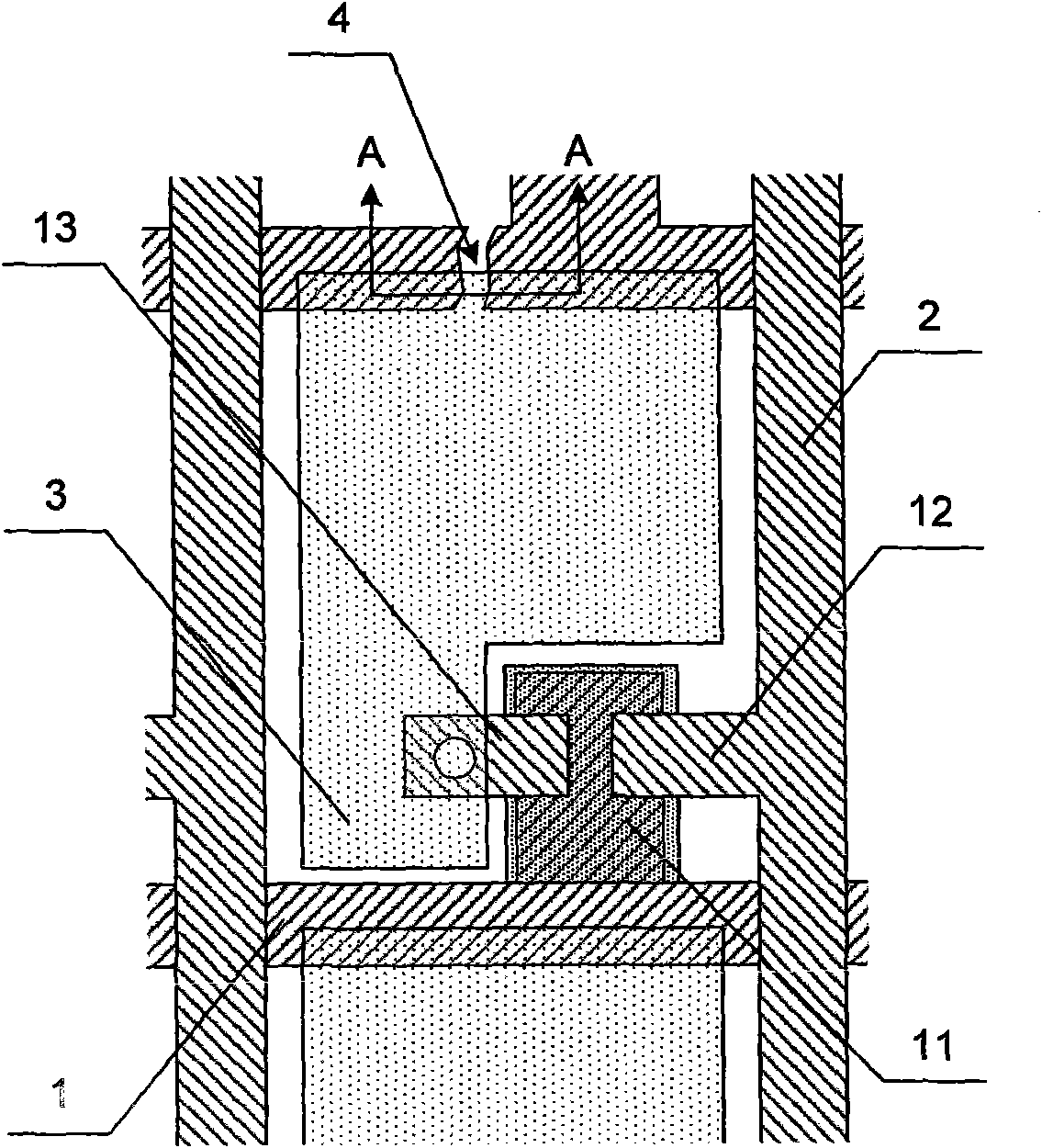

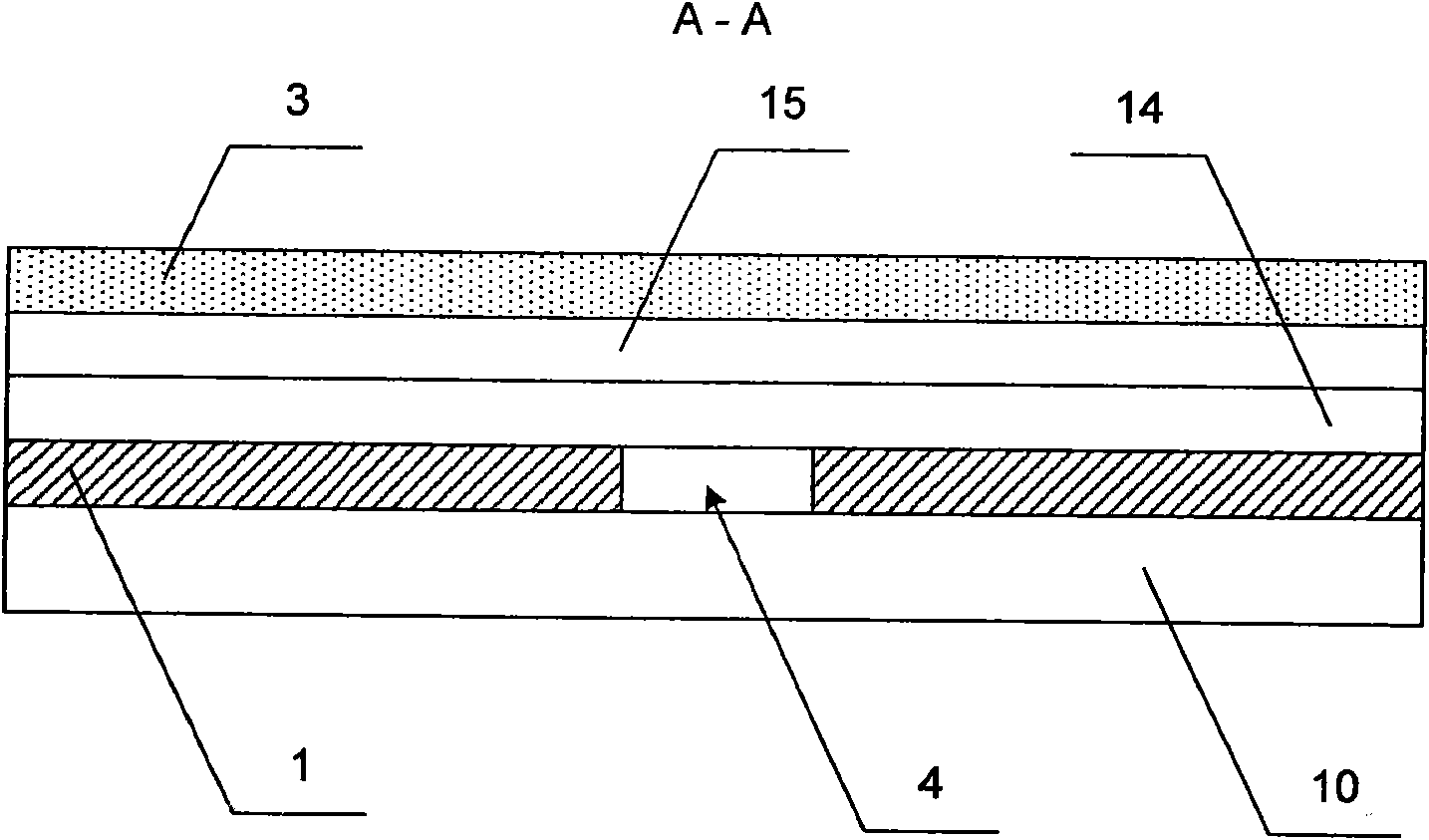

[0036] figure 2 Figure 8 It is a schematic diagram of the first embodiment of the method for repairing a broken line of a liquid crystal display of the present invention, wherein the array substrate of the liquid crystal display is a thin film transistor liquid crystal display (Thin FilmTransistor Liquid Crystal Display, referred to as TFT-LCD) array substrate, and the storage capacitor is located Typical pixel structure on Cst On Gate. The TFT-LCD array substrate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com