Color film substrate, manufacturing method thereof, display panel and display device

A color filter substrate and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of side viewing angle color mixing, lateral light leakage of display devices, etc., and achieve the effect of ensuring uniformity, ensuring display effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

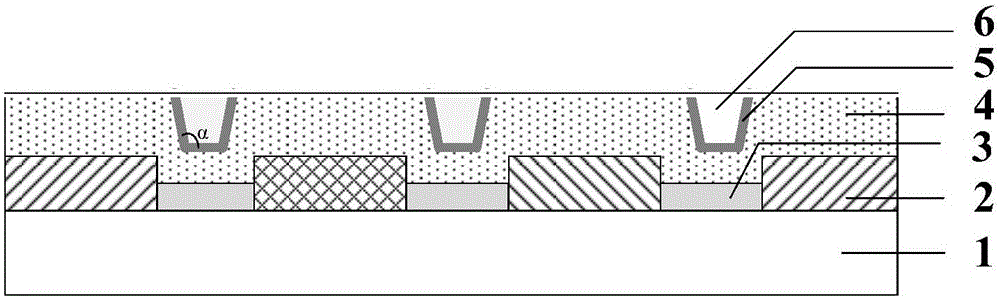

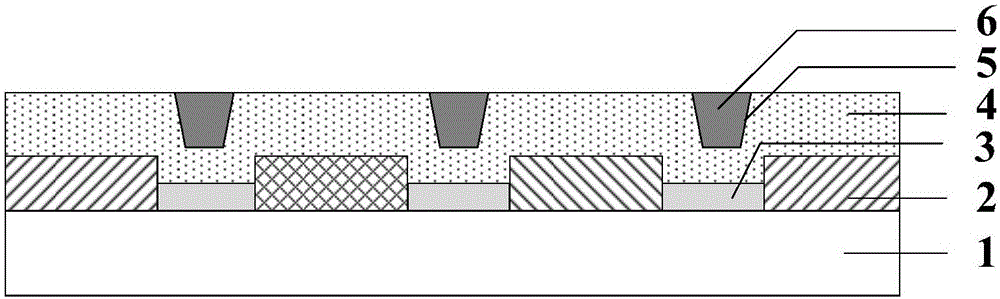

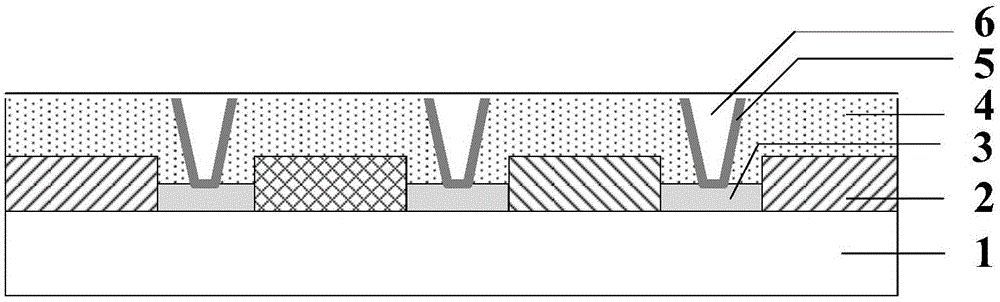

[0029] In order for those skilled in the art to better understand the technical solution of the present invention, the color filter substrate, display panel and display device of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0030] In the prior art, since the array substrate and the color filter substrate are prone to alignment errors, color mixing and light leakage at side viewing angles generally occur in display devices. For high-resolution liquid crystal display products and high color gamut LTPS (low temperature polysilicon) products, the possibility of color mixing and light leakage at side viewing angles is greater.

[0031] In order to solve this problem, the inventor found that black matrix light-shielding protrusions can be made in the area where the black matrix is located between adjacent color filter units or the thickness of the black matrix can be increased to prevent color mixing betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com