Backlight module and liquid crystal display device

A technology of backlight module and light source, which is applied in the direction of lighting devices, fixed lighting devices, parts of lighting devices, etc. It can solve the problems of easy deviation of film materials, inconvenient assembly, and easy entry of foreign objects, so as to prevent film material from shifting Prevents entry of foreign matter, facilitates assembly, and improves brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

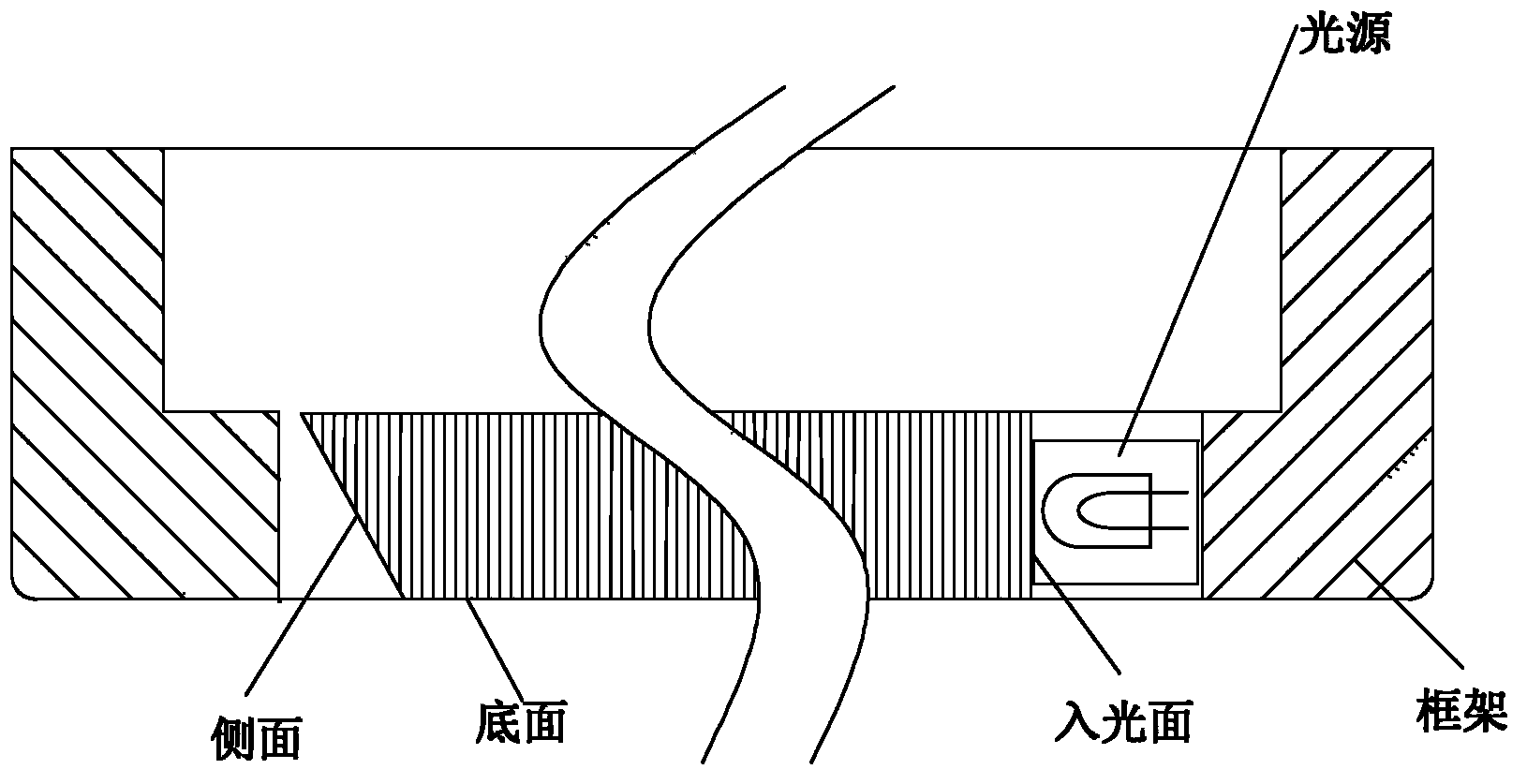

[0042] The backlight module described in this embodiment includes a light source, a frame and a film material for converting the light source into a uniform surface light source, wherein the frame accommodates the light source and the film material. The surface of the film material used to guide light to exit is the light-emitting surface, the surface opposite to the light-emitting surface is the bottom surface, and the surface adjacent to the light source is the light-incident surface.

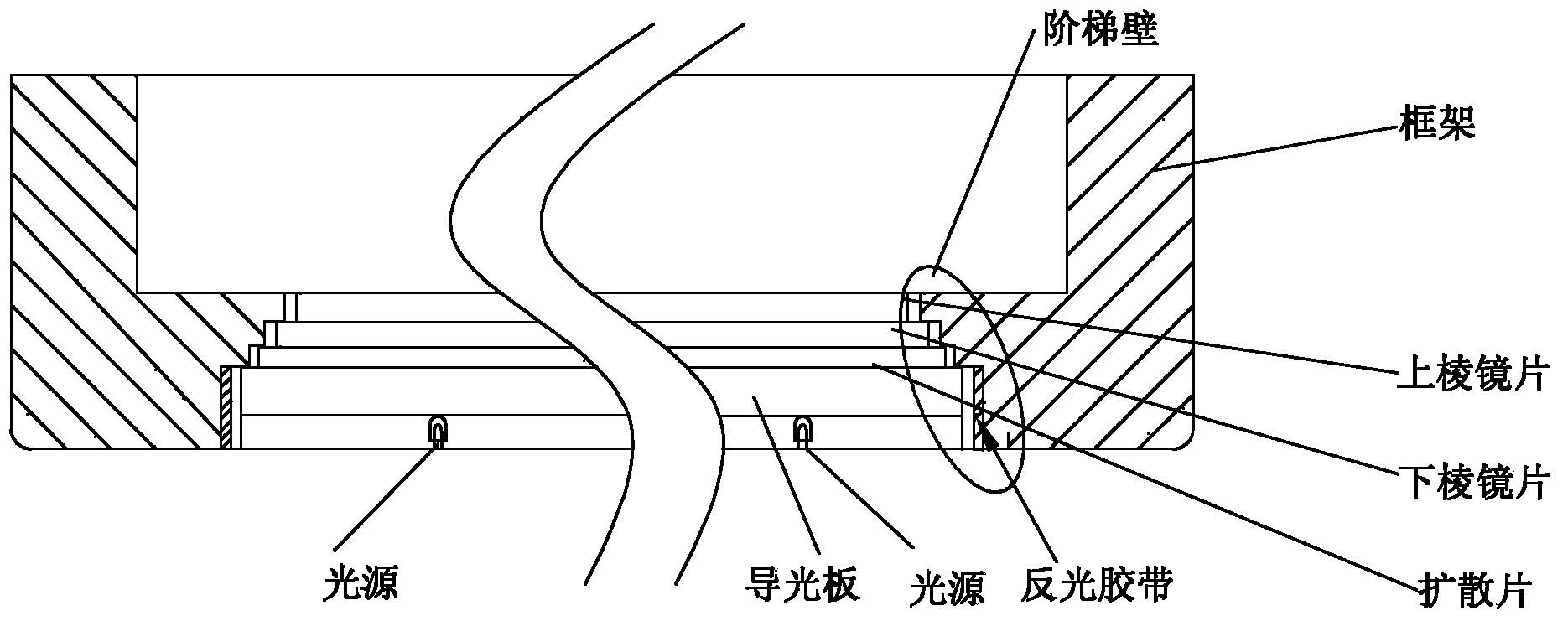

[0043] The film material is used to convert the light source into a uniform surface light source, and the film material may have slight differences according to different processes. The composition of the film material in this embodiment is as follows from bottom to top: reflective sheet, light guide plate, diffusion sheet, lower prism sheet, and upper prism sheet.

[0044] The frame accommodates the light source and the film material, and the light source can be located under the film materi...

Embodiment 2

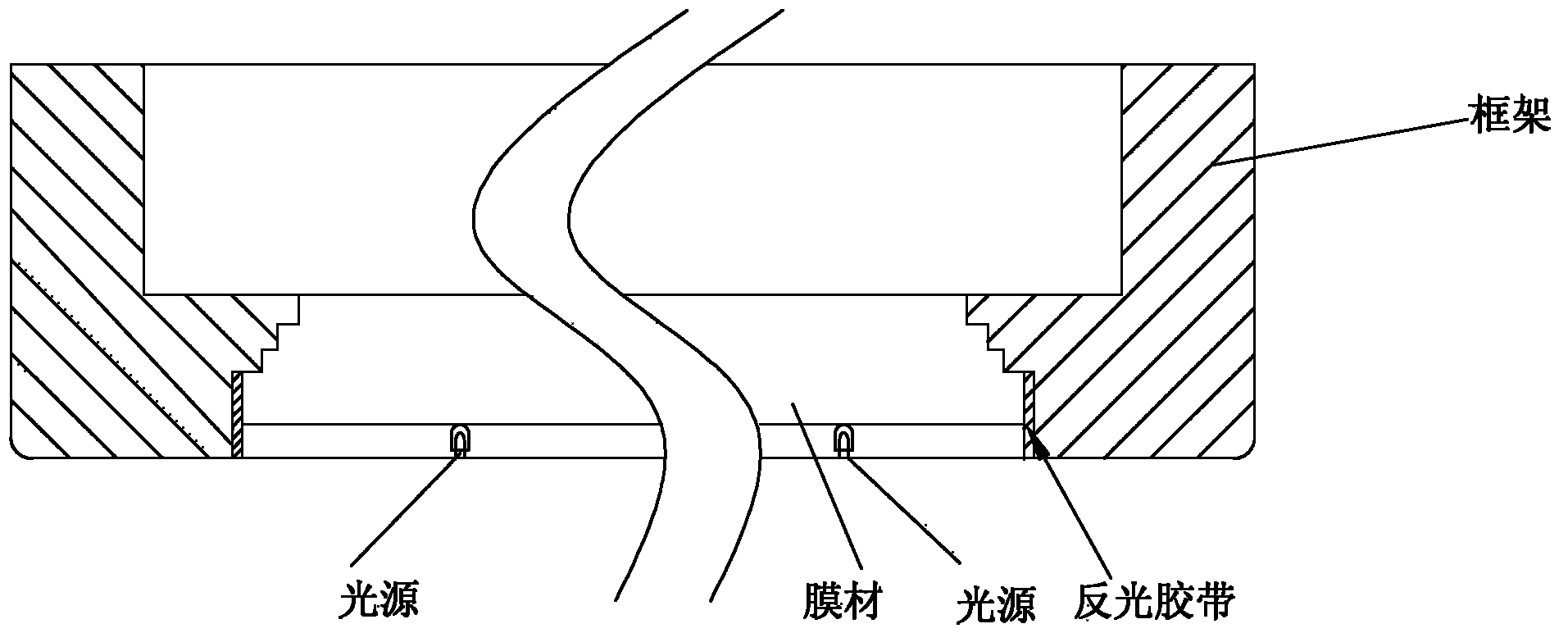

[0052] This embodiment provides a direct-type backlight module. The surface of the film material used to guide light to exit is the light-emitting surface, the surface opposite to the light-emitting surface is the bottom surface, and the surface adjacent to the light source is the light-incoming surface. , then the bottom surface is the incident surface. Any one, two or three of the four sides may be in a stepped shape, or all four sides may be in a stepped shape.

[0053] The present embodiment and prior art progress are:

[0054] For the direct-type backlight module, in the film material, except for the four sides other than the light-emitting surface and the bottom surface, at least one of the other four sides intersecting the light-emitting surface has a stepped shape, and the stepped-shaped The side surfaces are sequentially expanded along the direction from the light-emitting surface to the bottom surface. Correspondingly, the side of the frame opposite to the stepped s...

Embodiment 3

[0072] This embodiment provides a side light type backlight module. The surface of the film material used to guide light to exit is the light-emitting surface, the surface opposite to the light-emitting surface is the bottom surface, and the surface adjacent to the light source is the light-incident surface. Any one of the three sides, two sides may be in a stepped shape, or all three sides may be in a stepped shape.

[0073] The present embodiment and prior art progress are:

[0074] For the side-light type backlight module, among the four sides of the film material except the light-emitting surface and the bottom surface, except for the surface receiving the light source, among the other three sides intersecting the light-emitting surface, there are at least One side is stepped, and the stepped side expands sequentially along the direction from the light-emitting surface to the bottom surface. Correspondingly, the side opposite to the stepped side of the film material in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com