Colorful film substrate and method for manufacturing same

A technology of a color film substrate and a manufacturing method, which is applied in the field of color film substrates and its manufacturing, can solve problems such as increasing elasticity and stability, and increasing the length of columnar spacers, so as to achieve increased stability and effective Elasticity, the effect of avoiding light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

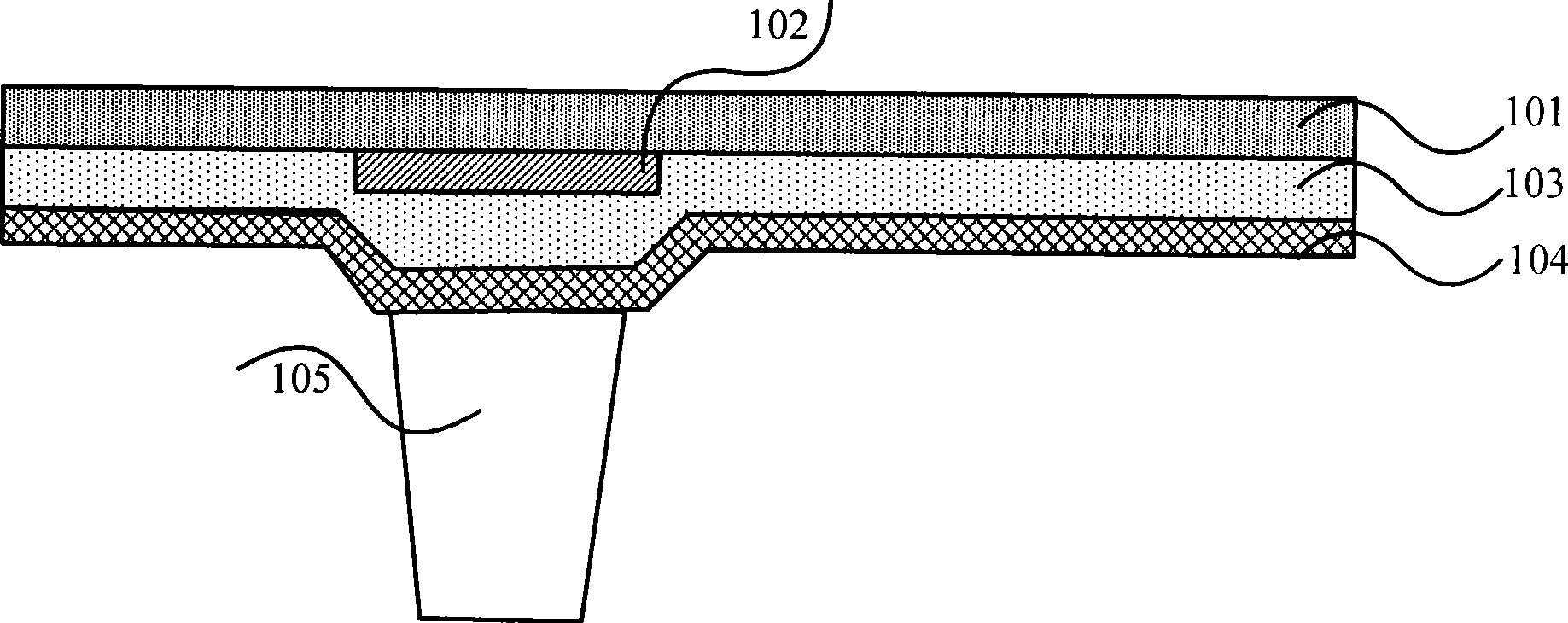

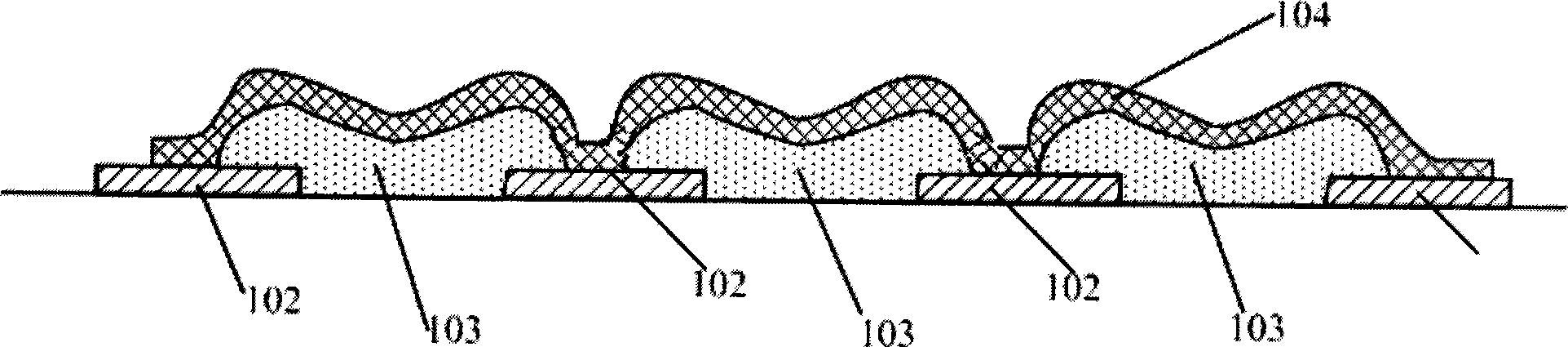

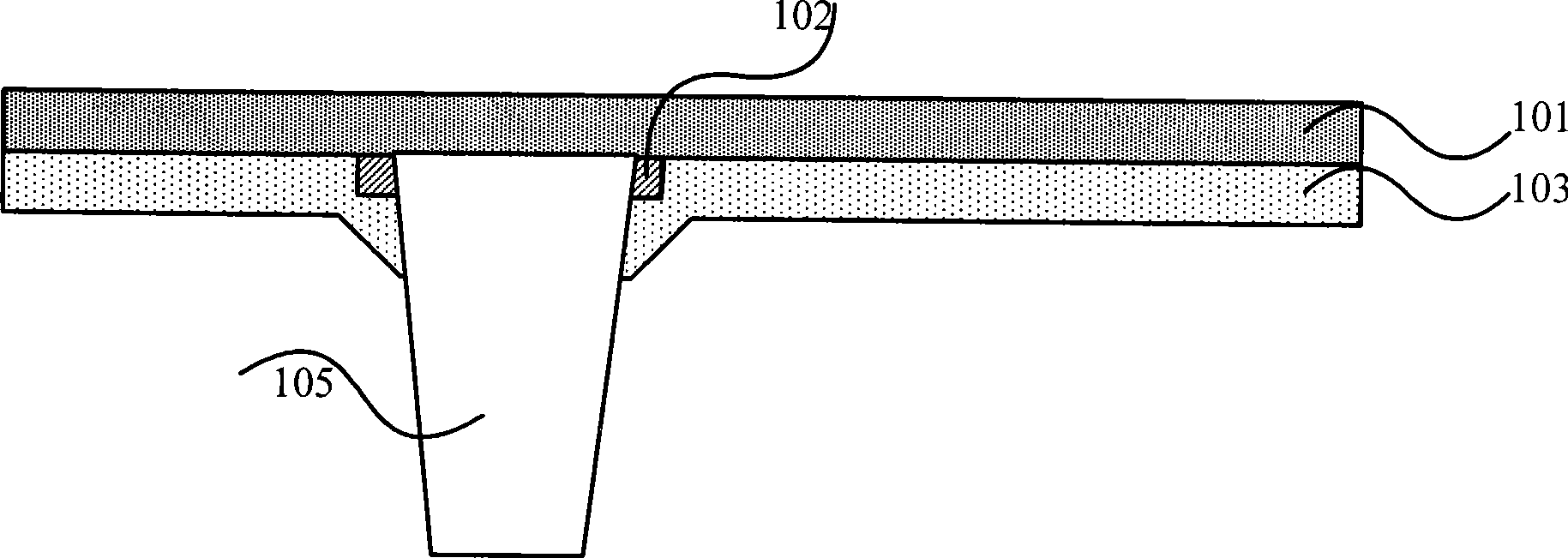

[0030] Such as figure 2 As shown, it is a cross-sectional view of the color filter substrate of the present invention. The color filter substrate includes a glass substrate 101, a columnar spacer 105, a black matrix 102 and a pixel resin 103. One end of the columnar spacer 105 is fixed on the glass substrate 101, and the other One end is suspended; the black matrix 102 is formed on the glass substrate 101 and is located around the columnar spacer 105, so that the black matrix 102 tightly wraps the root of the columnar spacer 105, exposing the other end of the columnar spacer 105 suspended; the pixel resin 103 Formed on the glass substrate 101 and the black matrix 102 , the pixel resin 103 covers the entire glass substrate 101 , exposing the other end of the column spacer 105 suspended in the air. In this embodiment, a common electrode 104 may also be included, and the common electrode 104 is formed on the pixel resin 103 , exposing one end of the columnar spacer 105 suspended...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com