Color film substrate as well as manufacturing method and display device thereof

A color filter substrate and manufacturing method technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as reducing user experience, light leakage of liquid crystal panels, affecting the display quality of liquid crystal display devices, etc., to increase the thickness of liquid crystal cells, improve Display quality, the effect of solving the problem of peripheral light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

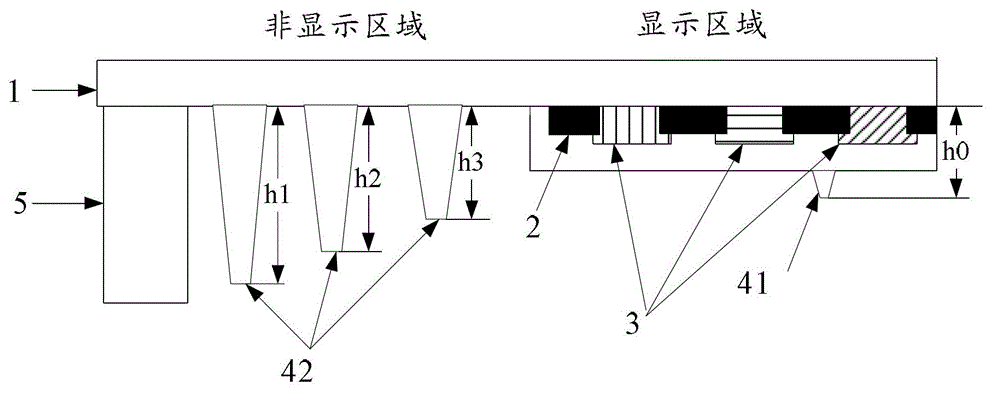

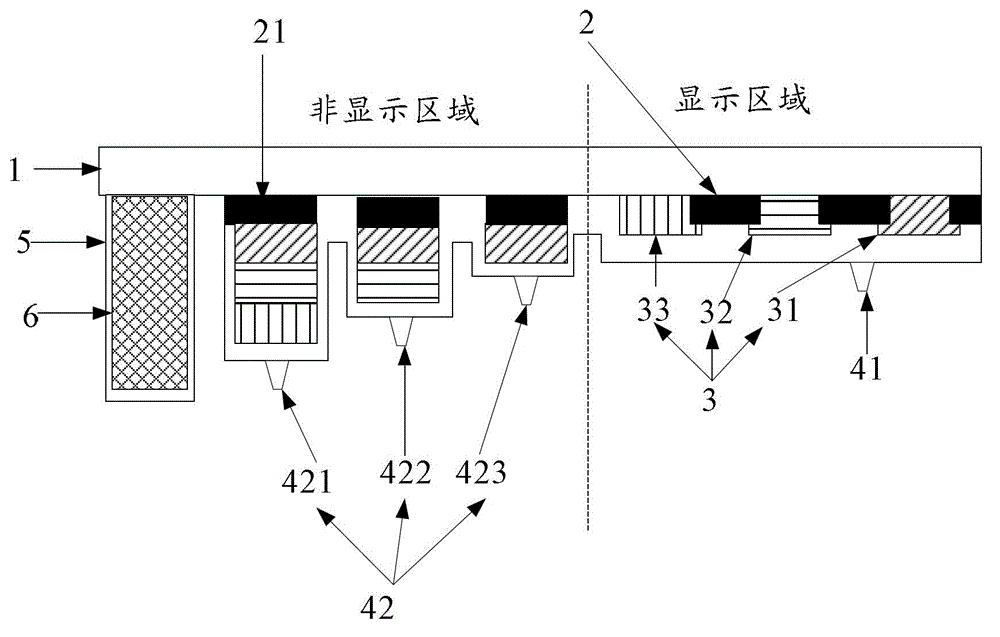

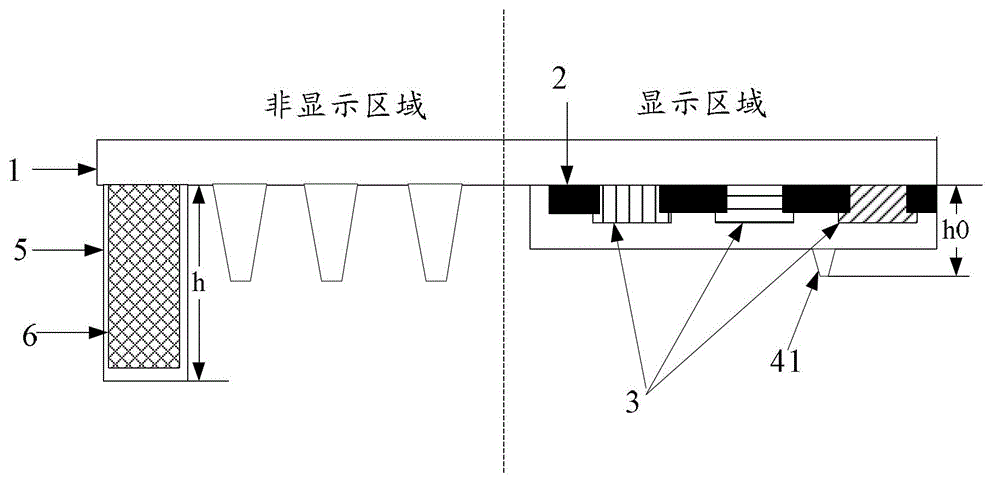

[0061] An embodiment of the present invention provides a color filter substrate, such as image 3 As shown, it includes a transparent substrate 1 , a black matrix 2 and a color filter 3 arranged on the transparent substrate 1 .

[0062] A display area spacer 41 is provided in the display area of the color filter substrate, and a sealant layer 5 is provided in the non-display area of the color filter substrate, and the top end of the sealant layer 5 is inserted into the transparent substrate. The height value h of the surface is greater than the height value h0 from the top of the display spacer 41 to the inner surface of the transparent substrate, and the difference between the two height values h-h0 is a preset value, so that the thickness of the liquid crystal cell is increased, Reduces the possibility of light leakage.

[0063] Under normal circumstances, the brightness value of light leakage that can be perceived by the naked eye is 0.4nit (nit), 1nit=1cd / m2 (candel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com