Backlight module

A technology of backlight module and backlight source, applied in the directions of optics, light guide, light source, etc., can solve the problem of light leakage of the backlight module, so as to improve the light efficiency and solve the effect of light leakage on the light-incident side.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

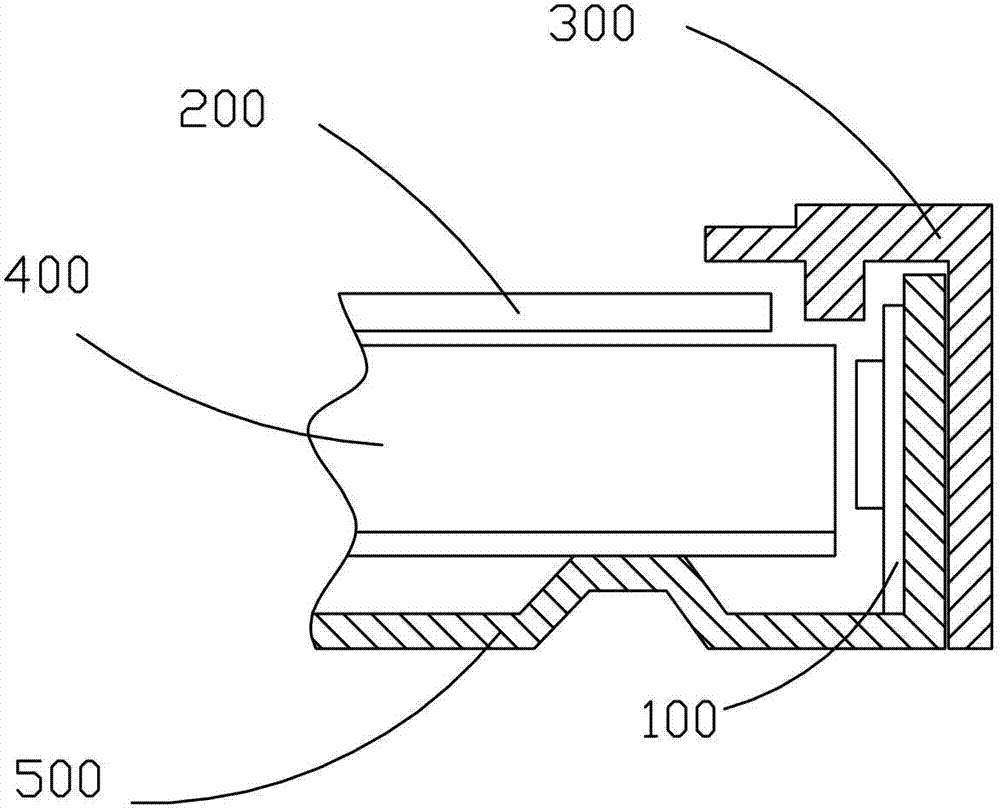

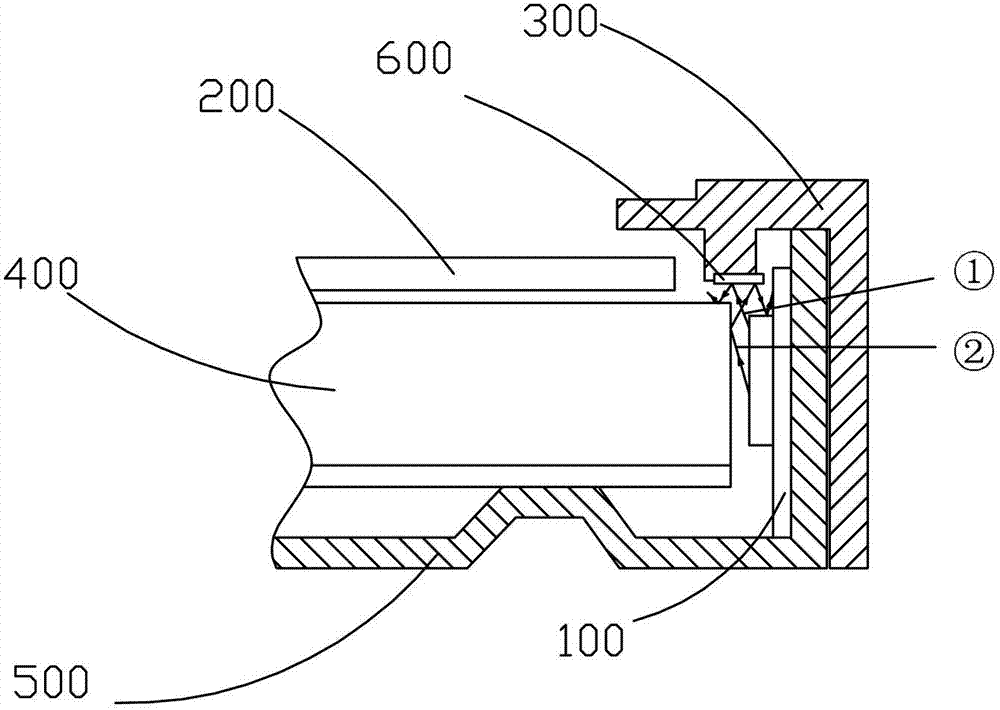

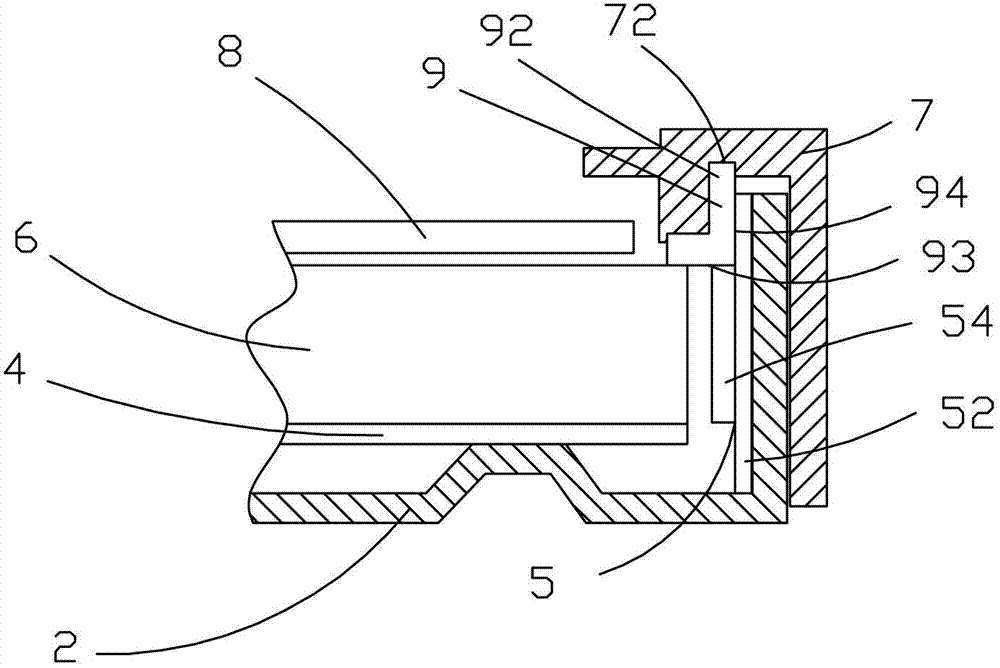

[0032] see image 3 , the present invention provides a backlight module, which includes: a backplane 2, a reflective sheet 4 arranged in the backplane 2, a light guide plate 6 arranged on the reflective sheet 4, an optical film group arranged on the light guide plate 6 8. The backlight 5 arranged in the backplane 2 and opposite to the light guide plate 6, the plastic frame 7 arranged on the backplane 2, and the backlight 5 and the light-incoming end of the light guide plate 6 are arranged above the light-incoming end and are tightly plugged and pasted. The elastic retaining wall 9 is attached or fixed on the plastic frame 7. The elastic retaining wall 9 includes a bottom surface 93 and a side surface 94 perpendicular to the bottom surface 93. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com