Thin film transistor array substrate and fabricating method thereof

A technology of thin film transistors and array substrates, which is applied in the field of display panels and its manufacturing, and can solve problems such as light leakage in peripheral circuit areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

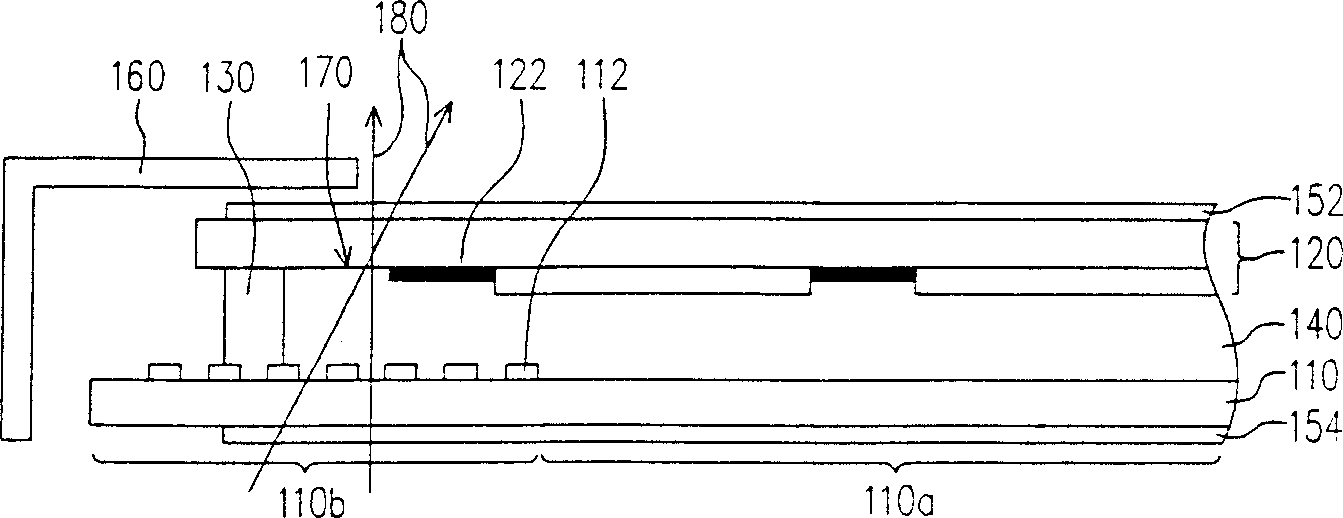

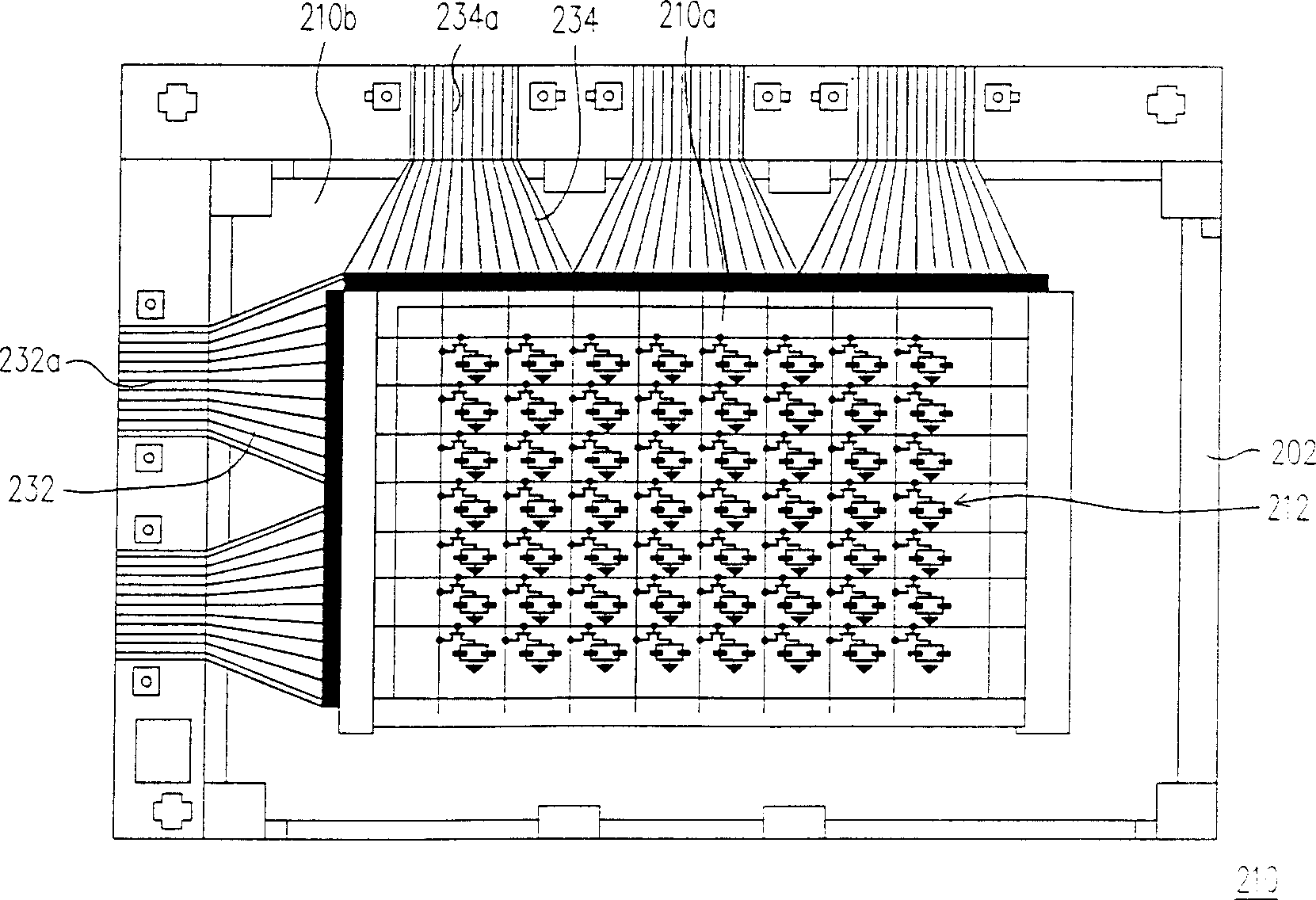

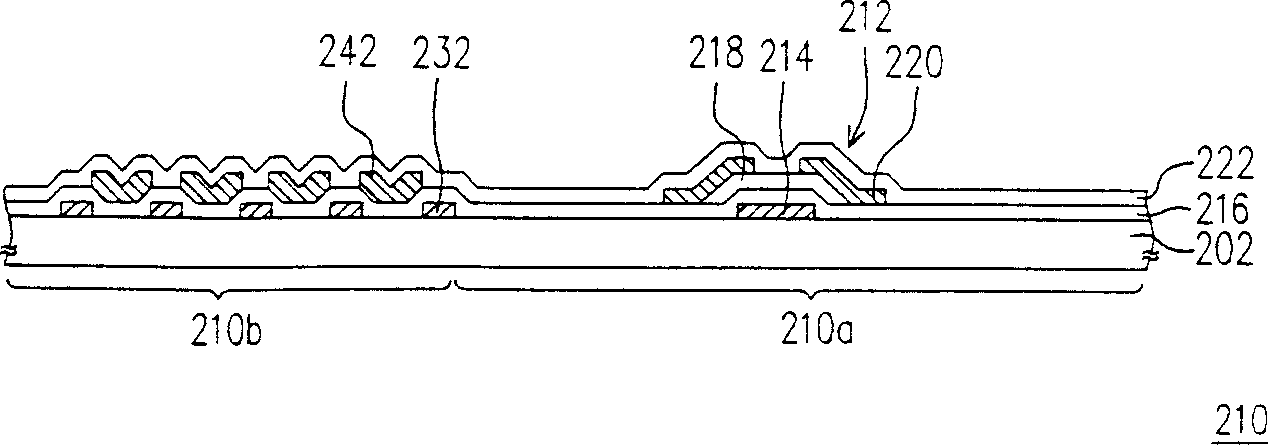

[0047] Please refer to figure 2 and 3 , figure 2 and 3 They are respectively a top view schematic diagram and a partial cross-sectional schematic diagram of a thin film transistor array substrate of the present invention. The thin film transistor array substrate 210 can be divided into, for example, a pixel area 210a and a peripheral line area 210b located on the periphery of the pixel area 210a, wherein the transparent substrate 202 in the pixel area 210a is provided with a thin film transistor array 212 composed of a plurality of thin film transistors and pixel electrodes. (not shown in the figure), and the transparent substrate 202 in the peripheral circuit area 210 b is provided with a plurality of leads connected to the thin film transistor array, which may be gate wiring 232 or source wiring 234 , for example. In addition, the ends of the gate wiring 232 and the source wiring 234 are respectively connected to a plurality of first pads 232 a and a plurality of second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com