Auxiliary unloading device for circular wound needle, cable core winding equipment and cable core forming method

An auxiliary unloading device, a circular technology, which is used in battery assembly machines, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc. Wrinkles and slumps, compact structure, quality-assured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

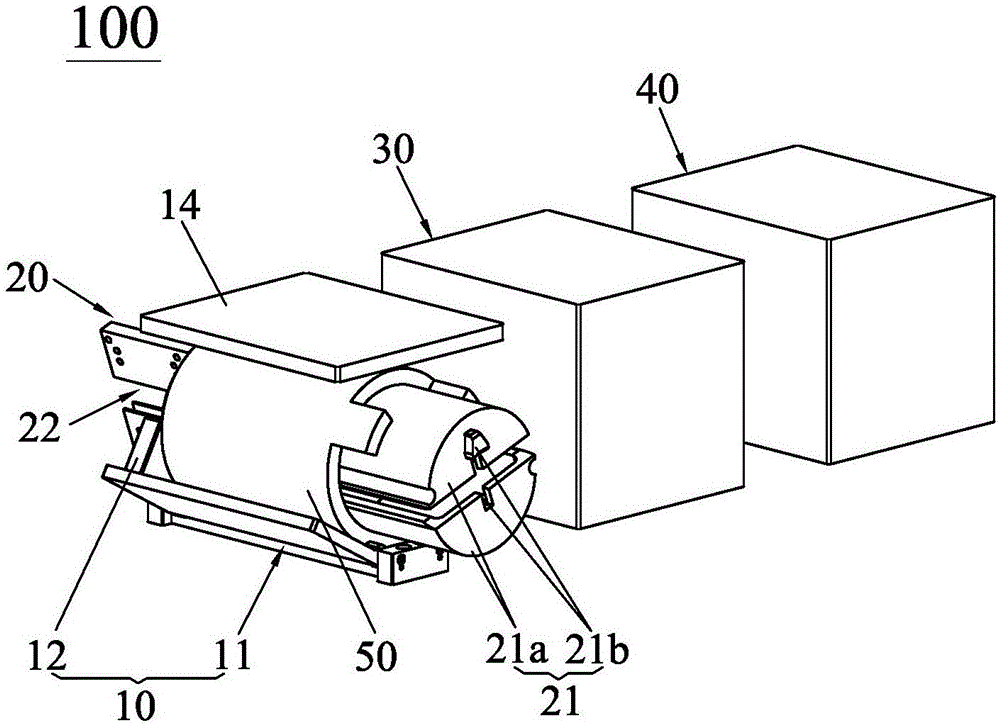

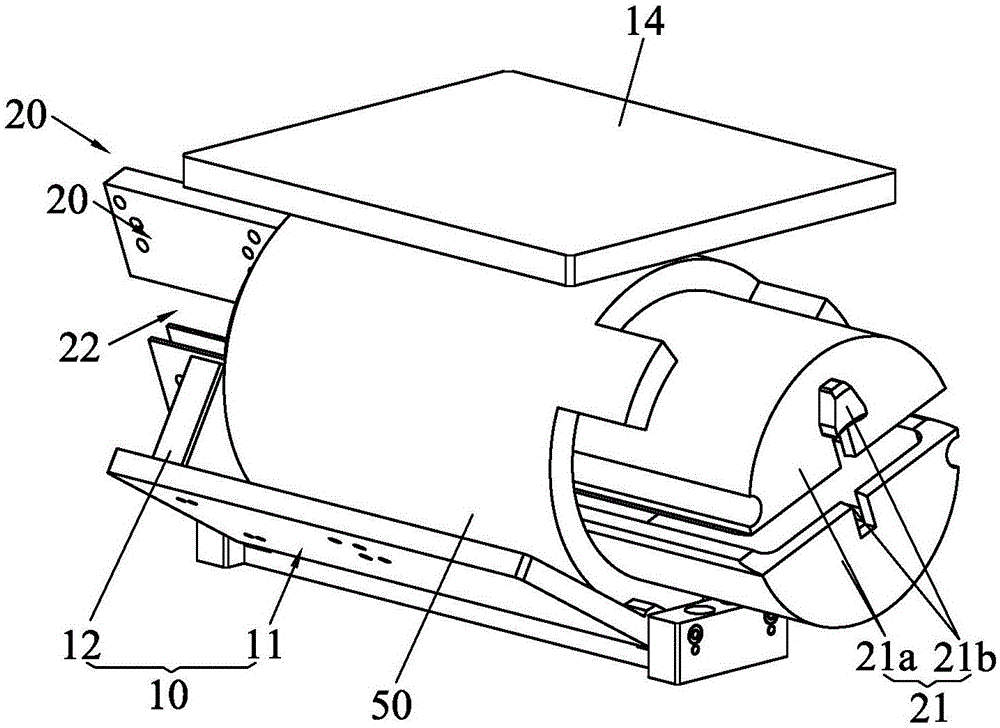

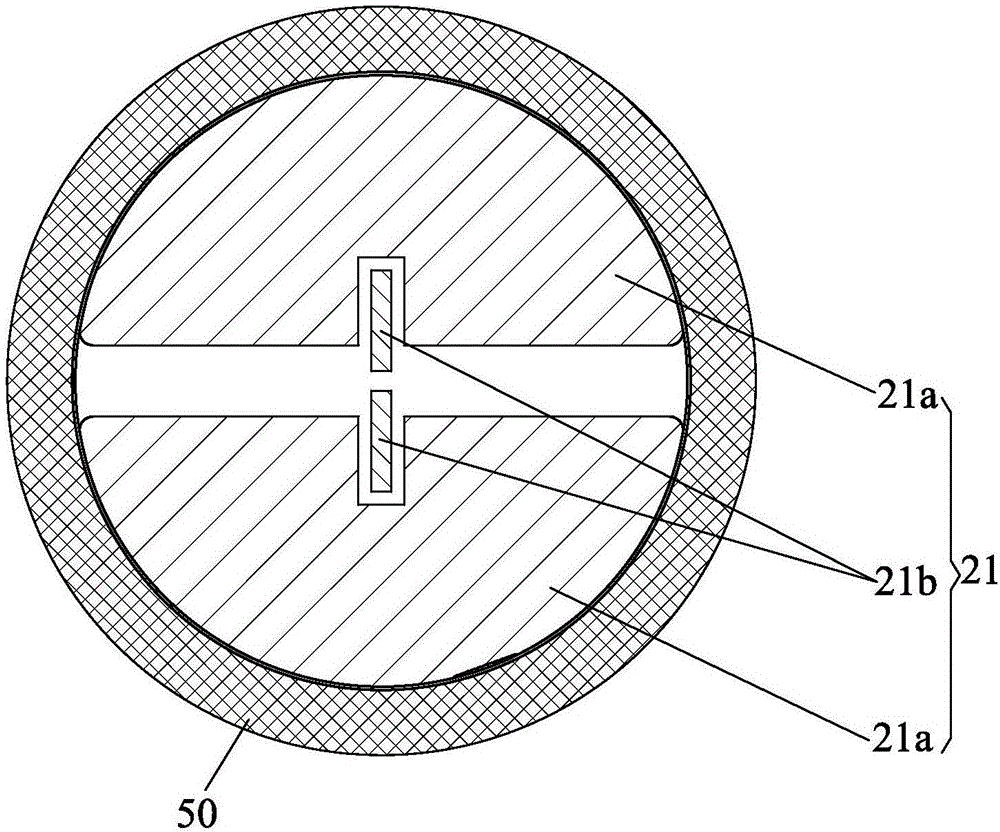

[0037] see figure 1 and figure 2 , The cell winding equipment 100 of the present invention includes an auxiliary unloading device 10 for circular needle winding, a circular needle winding mechanism 20 , a secondary pre-pressing mechanism 30 and a thermoforming mechanism 40 . The circular needle winding mechanism 20 is used to wind the diaphragm and pole pieces out of the circular battery core 50, so as to overcome the problem that the elliptical winding needle produces fluctuations during winding, so that the circular battery core 50 can be wound smoothly and can High-speed winding, the line speed can reach more than 1m / s during winding, so as to improve productivity; specifically, combined with image 3 , in this embodiment, the circular needle rolling mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com