Vertical brown sugar production sanding equipment

A brown sugar, vertical technology, which is applied in the field of sand blasting devices for brown sugar production, can solve the problems of high labor intensity, high resistance to agitation, syrup splashing, etc., to reduce labor intensity, facilitate unloading and cleaning, and simple and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

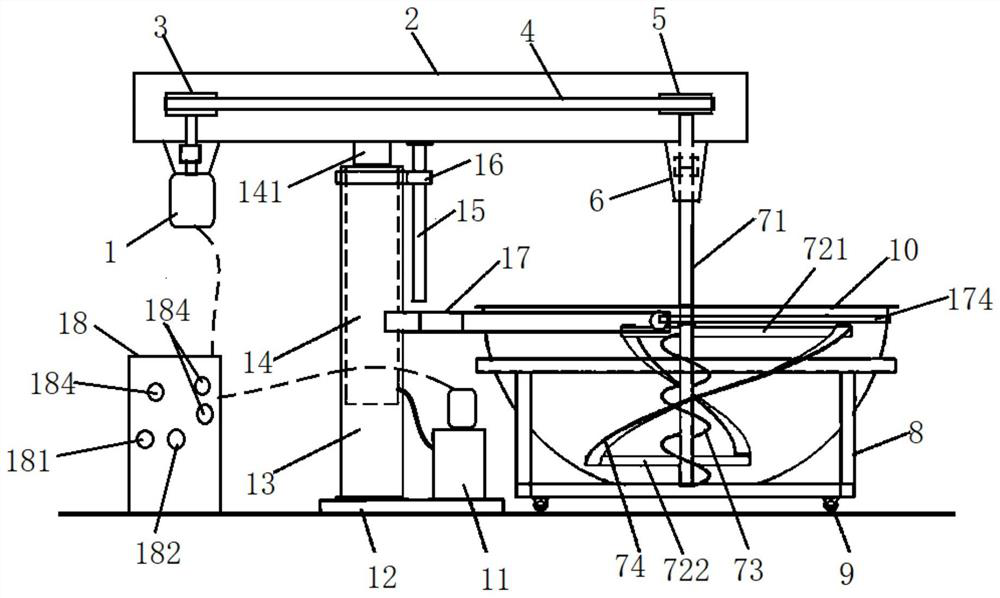

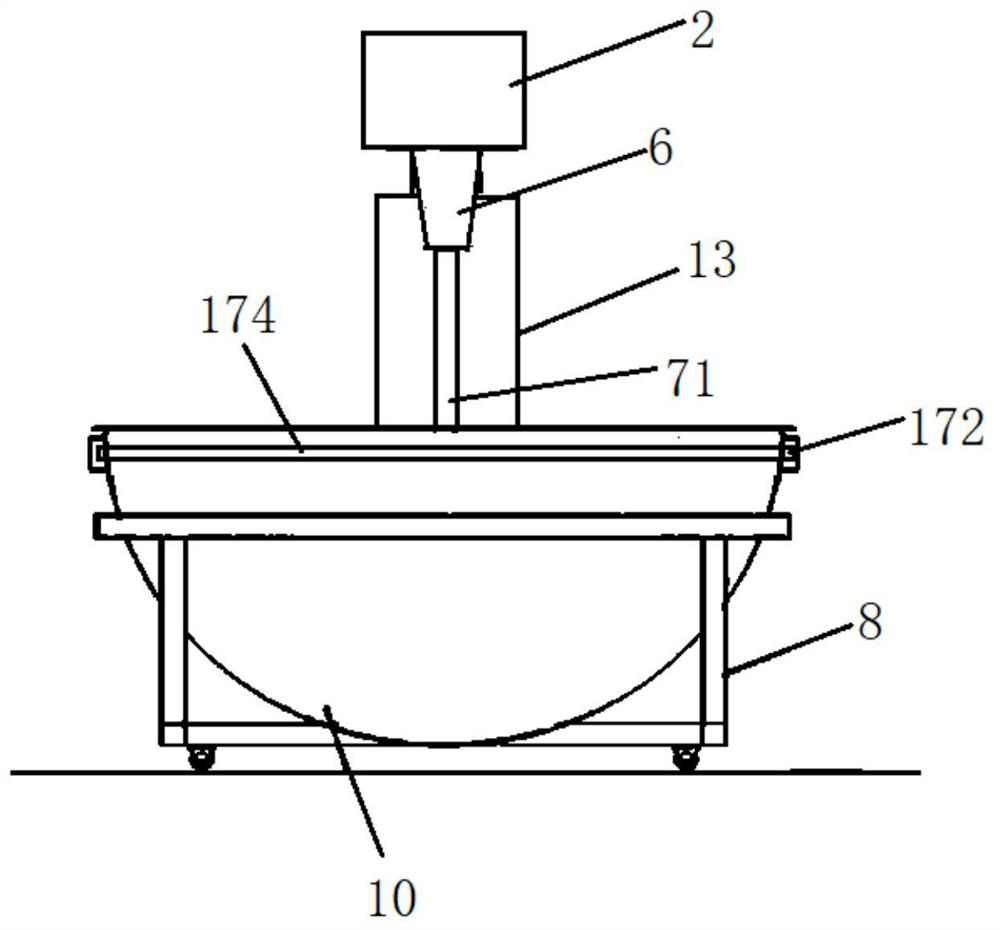

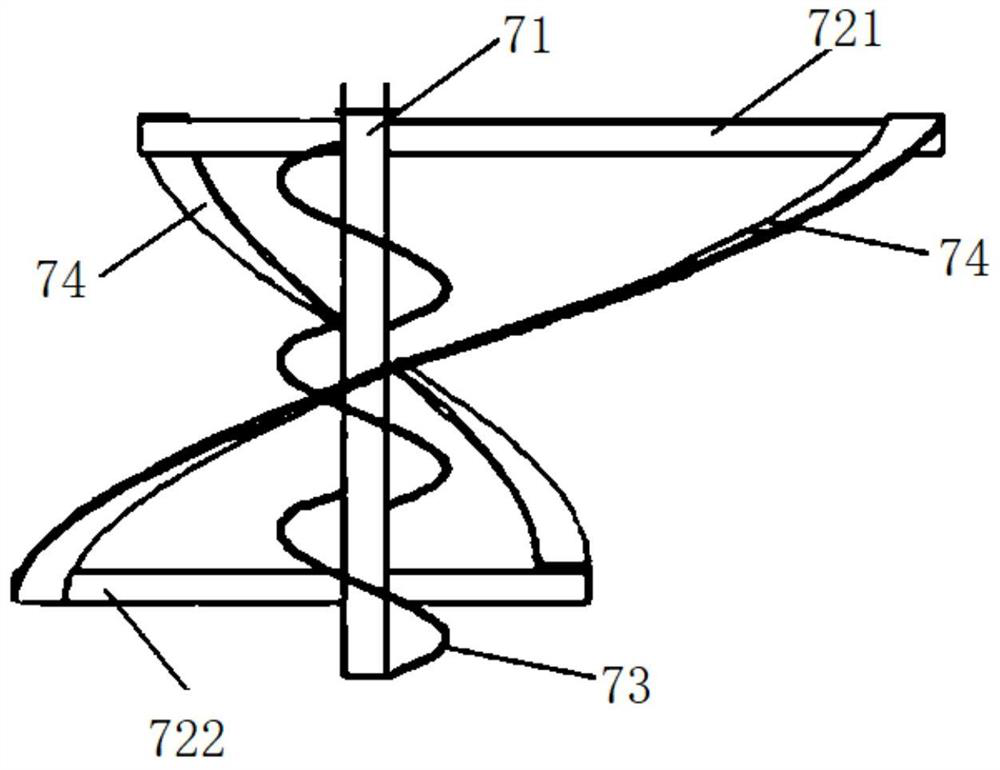

[0025] Such as figure 1 , figure 2 The vertical sanding device for brown sugar production shown includes a hydraulic lifting device, a transmission device installed on the top of the hydraulic lifting device, a sanding and stirring device driven by the transmission device, a mobile casserole that can be inserted into the sanding and stirring device, an electric control cabinet.

[0026] The hydraulic lifting device includes a column 13, a hydraulic cylinder 14 with a piston rod 141 mounted on the column facing upwards, a guide seat 16 installed on the column, and a vertical travel guide rod 15 vertically inserted in the guide seat that can be lifted and lowered. , connect the hydraulic pump 11 of the hydraulic cylinder. The column 13 is fixedly installed on the base 12, and the base 12 is fixed to the ground by anchor bolts. A tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com