Assembling and disassembling system for port container and assembling and disassembling technology thereoffor

A container and process technology, applied in the port container handling system and its process field, can solve the problem of low efficacy and achieve the effect of low energy consumption and high-efficiency investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

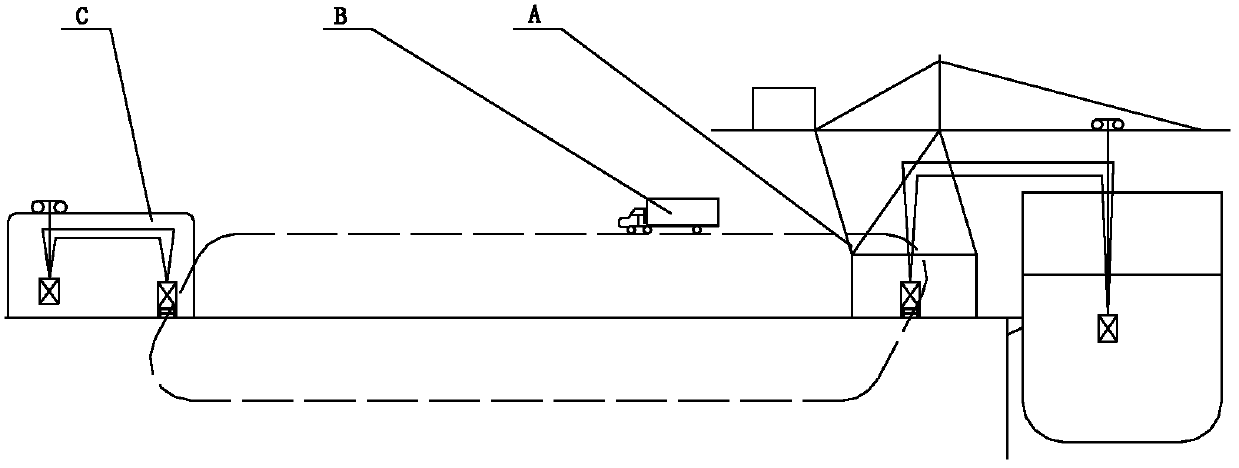

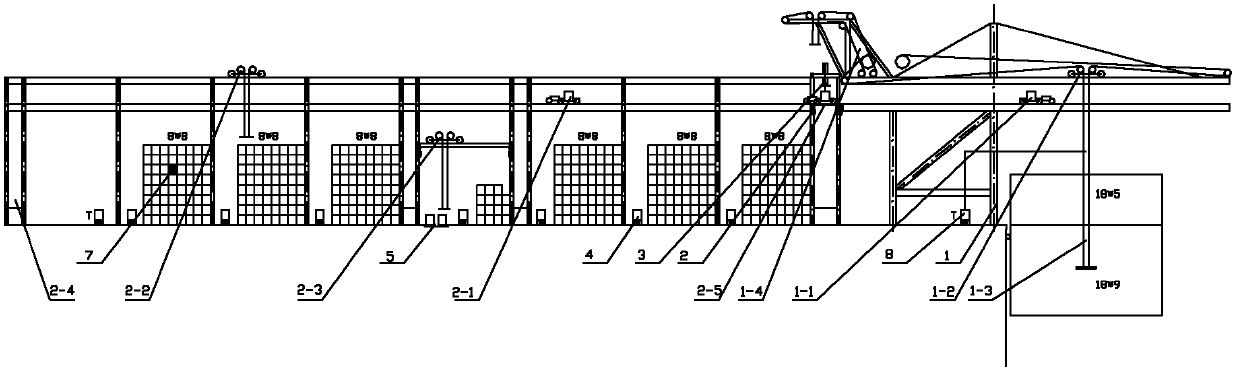

[0050] The port container loading and unloading system and its process of the present invention will be described in conjunction with the accompanying drawings and embodiments.

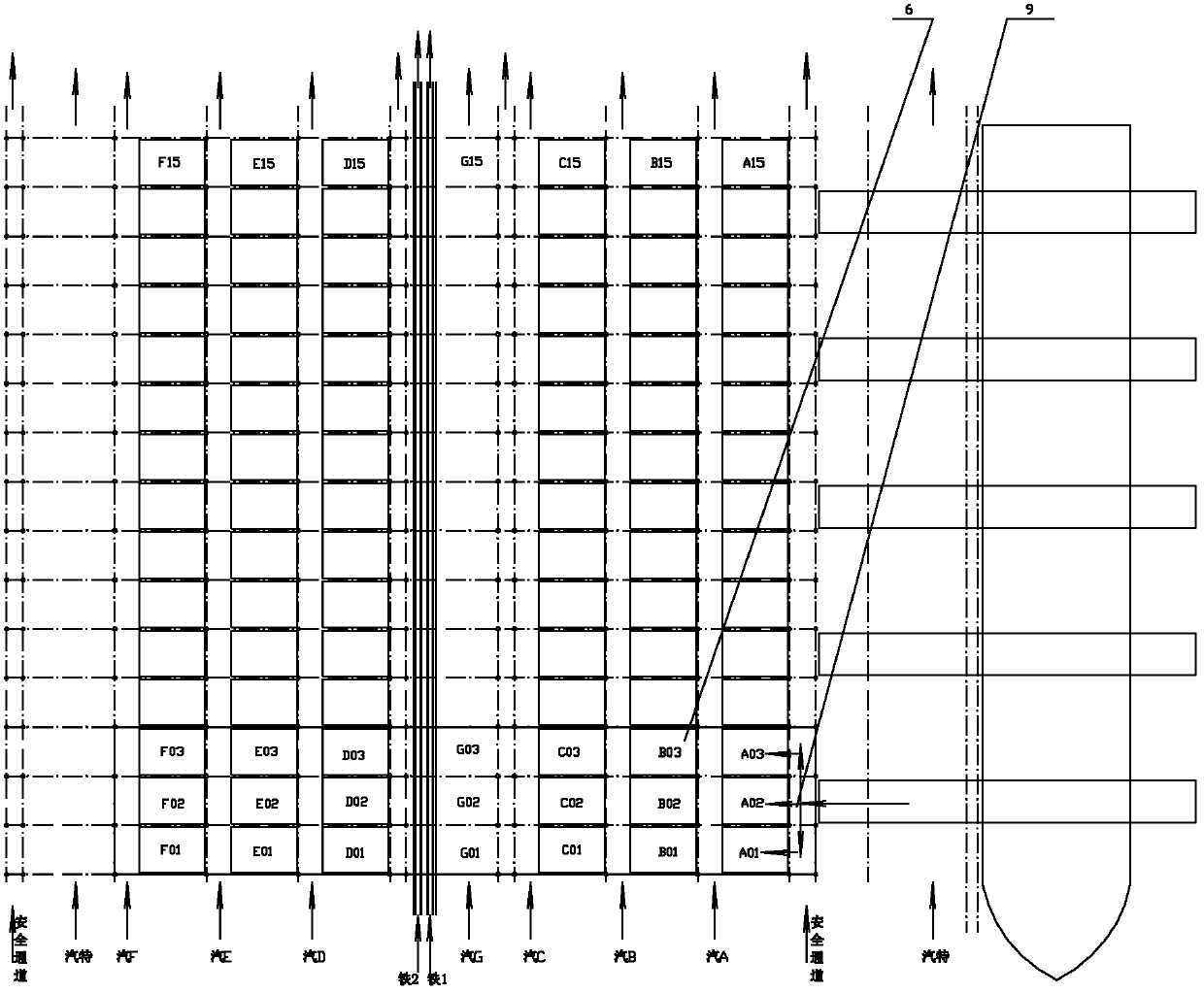

[0051]The port container loading and unloading system of the present invention comprises the quay bridge and the quay bridge transfer trolley on the wharf yard, the fixed elevated trestle behind the quay bridge and the ferry bridge, the trestle bridge transfer trolley and the yard bridge on the said dock. Another track beam parallel to it is provided under the track beam of the lifting trolley 1-2 of the quay bridge 1, and the transfer trolley 1-1 of the quay bridge runs on the other track beam, and the other track beam is set It is beneficial for the rubber tires of the transfer trolley to run on the U-shaped track with ribs. The elevated trestle 2 is provided with a ferry bridge 3, a trestle transfer trolley 2-1 and a field bridge 2-2;

[0052] The elevated trestle 2 is provided with upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com