Compressing device and edge wrapping equipment

A technology of pressing device and pressing block, which is applied in the field of pressing device and hemming equipment, and can solve the problems of substandard quality of finished interior canopy, easy wrinkling, uneven tension of decorative fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

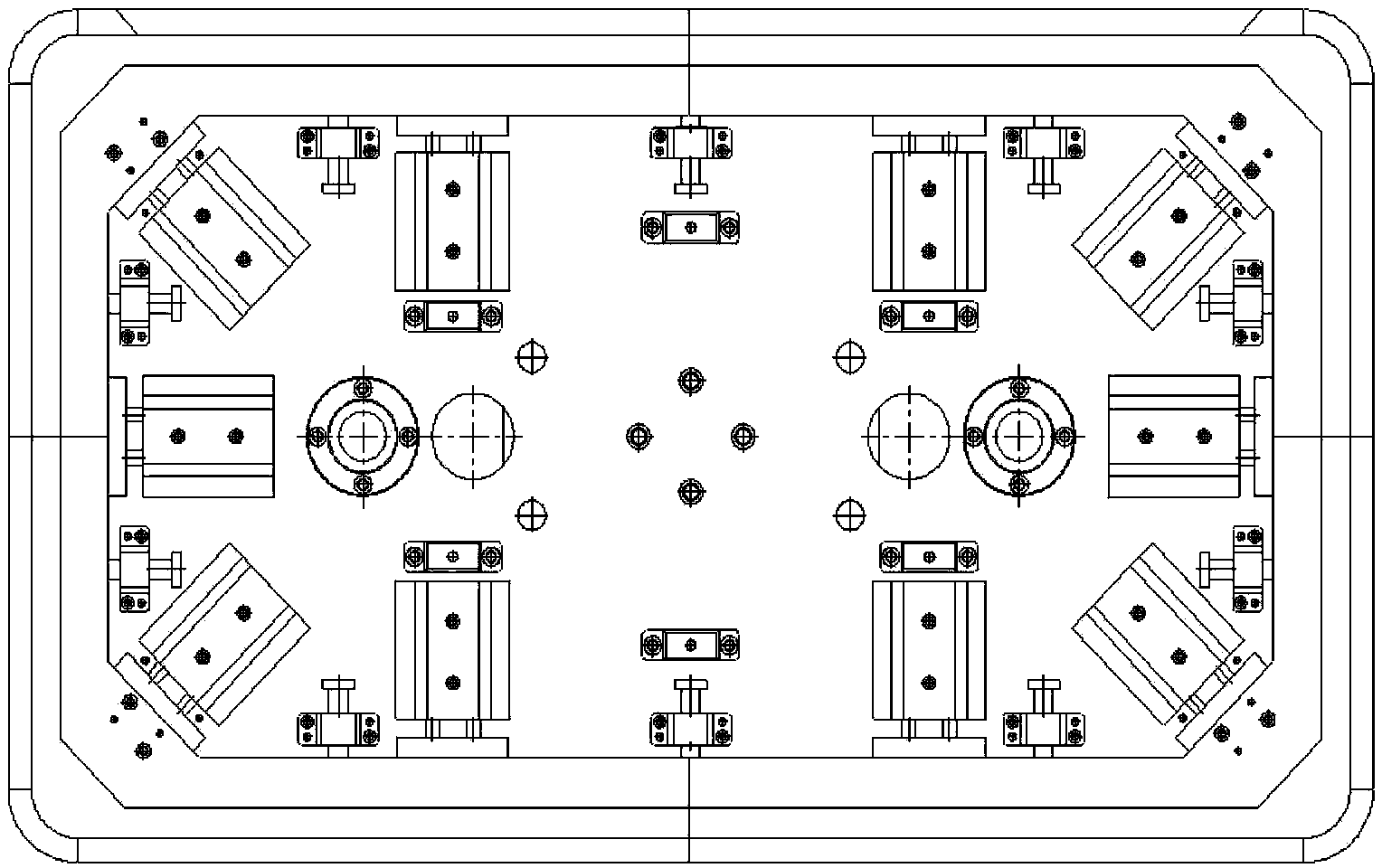

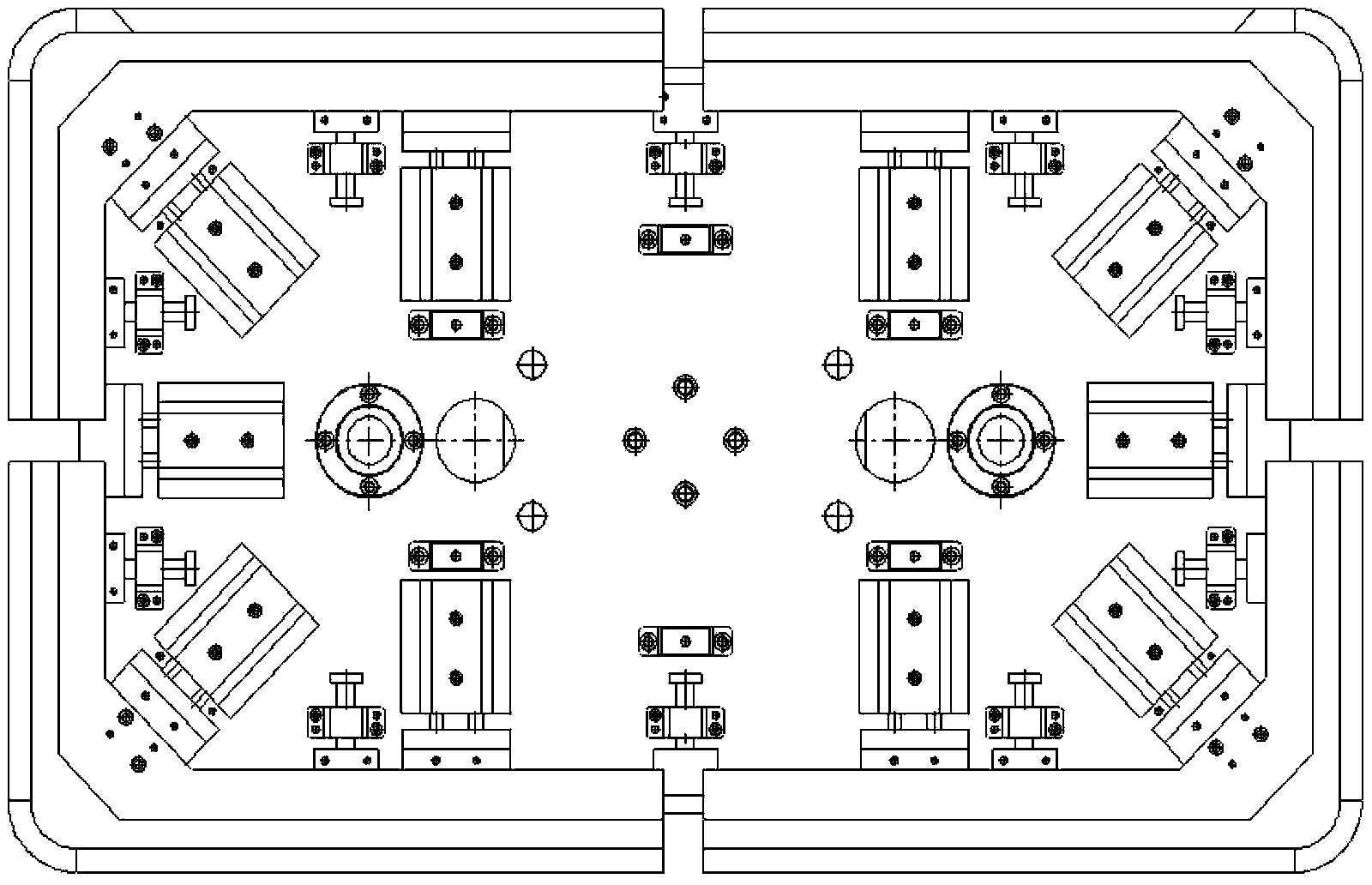

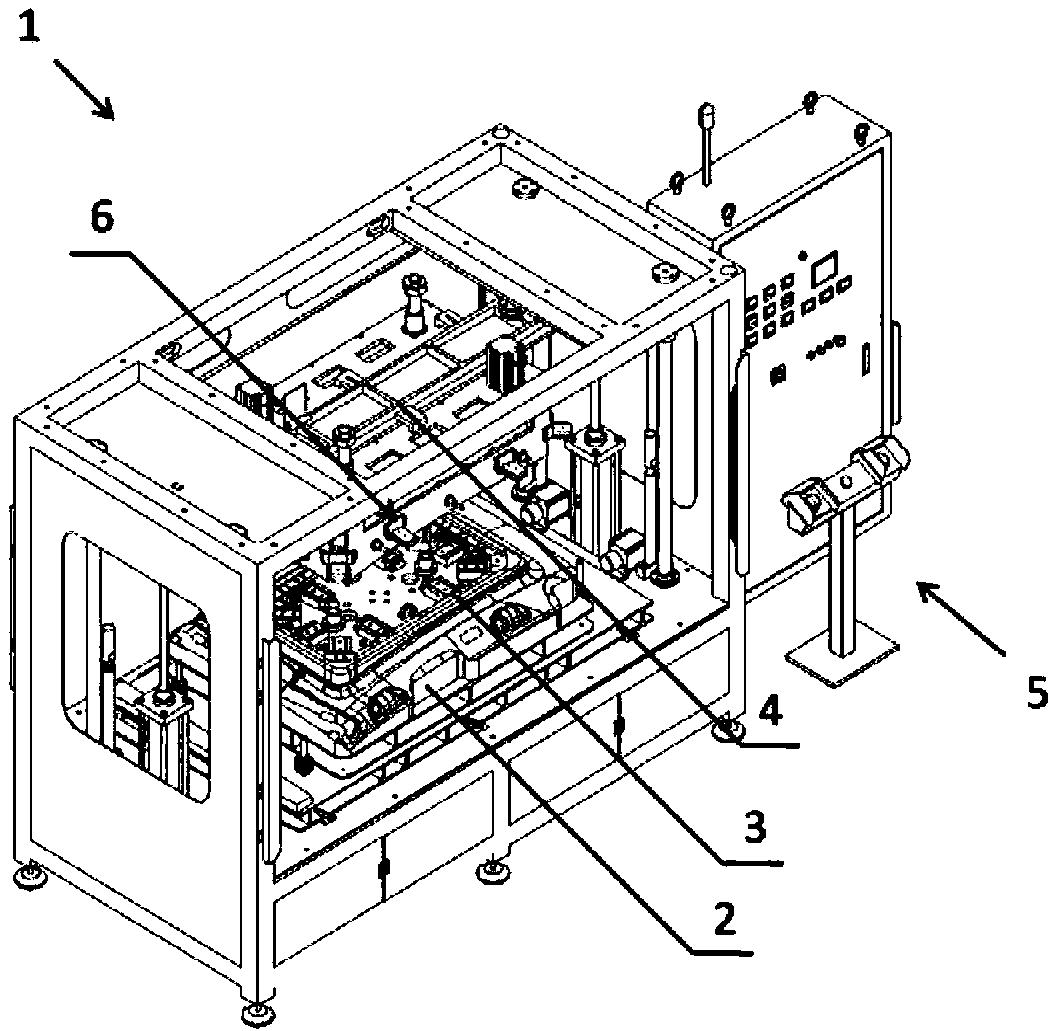

[0047] image 3 It is a structural schematic diagram of the hemming equipment of the embodiment of the present invention.

[0048] Figure 4 It is the front view of the hemming equipment of the embodiment of the present invention.

[0049] Figure 5 It is a block diagram of a hemming device according to an embodiment of the present invention.

[0050] like image 3 , 4As shown in , 5, the hemming device 1 is used to turn over and paste the edge material at the opening of the sunroof in the decorative fabric pasted on the inner surface of the semi-finished interior roof of the car and stick it to the outer surface of the semi-finished interior roof, including the electrification part 31. The control unit 5, the positioning device 2, the heating device 4, the flanging device 3 and the pressing device 6. Wherein, the pressing device 6 further includes a pressing mechanism 17 and a control mechanism 18 .

[0051] The control unit 5 is used to overall control and coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com