Bend forming method of large-angle pipeline with high precision, large pipe diameter and small bending diameter ratio

A technology of bending forming and large pipe diameter, applied in the field of machining, which can solve the problems of scratching the pipe blank, high manufacturing cost, and difficulty in removing the mandrel, and achieve the effect of continuous inner surface and good follow-up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

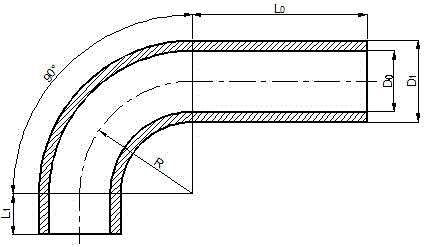

[0009] Take bending the steel pipe into a 90° elbow as an example, please refer to the shape of the 90° elbow figure 1 .

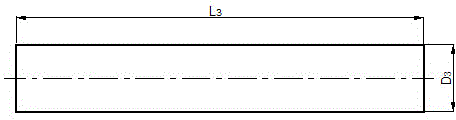

[0010] The first step is to determine the molding size. Thick-walled pipe is also called thick-walled steel pipe, the outer diameter of the steel pipe (D 1 ) and wall thickness ( ) The steel pipe with a ratio of less than 20 is called thick-walled steel pipe.

[0011] Bend-to-diameter ratio is the central curvature radius (R) of the elbow and the inner diameter of the elbow (D 0 ) ratio, which is an important parameter to describe the geometric characteristics of the elbow. The size of the bend diameter ratio accurately describes the bend degree of the bend pipe. As the bend pipe bend diameter ratio increases, the bend degree of the bend pipe will decrease. Generally, the bend pipe with R / D≤2 is a small bend diameter ratio pipe.

[0012] Large diameter pipe fittings refer to the inner diameter or diameter greater than 250mm (D 0 ≥250mm) pipe.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com