A kind of ultrahigh-strength low-stress aluminum alloy pipe and its preparation method

An ultra-high-strength, aluminum alloy tube technology, applied in the field of aluminum alloy preparation, can solve problems such as performance loss, achieve residual stress elimination, improve mechanical properties, and achieve significant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

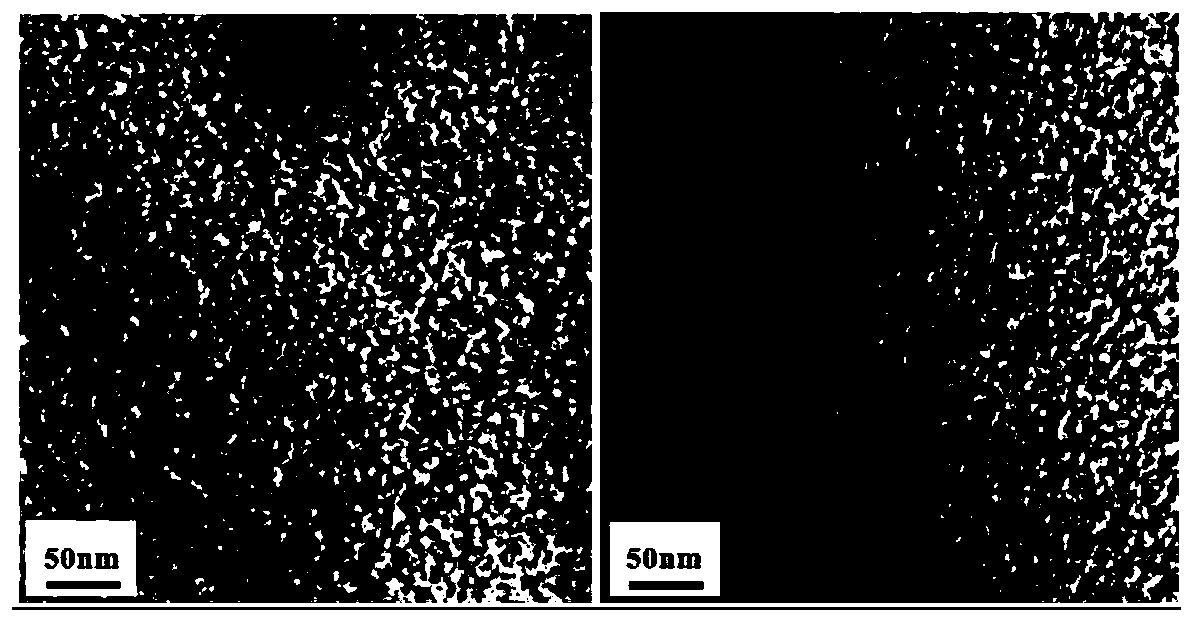

Image

Examples

Embodiment 1

[0038] A method for preparing an ultra-high-strength and low-stress aluminum alloy pipe, comprising the steps of:

[0039] (1) Insulate the extruded pipe at a solid solution holding temperature of 475°C for 4 hours, and immediately transfer it to room temperature water for quenching and cooling to room temperature.

[0040](2) Put the extruded pipe obtained in step (1) into a cryogenic treatment device, cool it to -200°C at a rate of 25°C / s, keep it warm for 40 minutes, and quickly transfer it to an oil tank after taking it out. The oil temperature is 160°C. The time is 20 minutes, and the heating rate is 35°C / min; after taking it out, put it into the cryogenic treatment device quickly, cool it to -200°C at a speed of 25°C / s, keep it for 20 minutes, and pre-stretch after taking it out, the stretching amount is 1.0% ; After stretching, put it into the cryogenic treatment device, cool it to -200°C at a rate of 25°C / s, keep it warm for 30 minutes, and quickly transfer it to an oi...

Embodiment 2

[0044] A method for preparing an ultra-high-strength and low-stress aluminum alloy pipe, comprising the steps of:

[0045] (1) Heat the extruded pipe at a solid solution holding temperature of 475°C for 4 hours, and then perform step-by-step quenching, wherein: the first stage of PAG quenching: the temperature of the extruded pipe is cooled from 475°C to 420°C, and the temperature of the PAG solution is 30°C. The rate is 15°C / s; the second stage water quenching: cool the extruded pipe after the first stage quenching to 230°C, the water temperature is 10-60°C, and the cooling rate is 80°C / s; the third stage water quenching: the second stage The extruded pipe after quenching is cooled to 60°C, the water temperature is 80°C, and the cooling rate is 10°C / s; this step ensures that the residual stress of the extruded pipe reaches the minimum after quenching and does not bend;

[0046] (2) After 1h, pre-stretch the extruded pipe obtained in step (1) until the material yields, then st...

Embodiment 3

[0050] A method for preparing an ultra-high-strength and low-stress aluminum alloy pipe, comprising the steps of:

[0051] (1) is identical with the step (1) of embodiment 2;

[0052] (2) is identical with the step (2) of embodiment 2;

[0053] (3) Put the extruded pipe obtained in step (2) into a cryogenic treatment device, cool it to -200°C at a rate of 25°C / s, keep it warm for 40 minutes, and quickly transfer it to an oil tank after taking it out. 30min, the heating rate is 35°C / min; after taking it out, put it into the cryogenic treatment device quickly, cool it to -200°C at a speed of 25°C / s, keep it warm for 20min, and pre-stretch after taking it out, the stretching amount is 1.0%; After stretching, put it into a cryogenic treatment device, cool it to -200°C at a rate of 25°C / s, keep it warm for 30 minutes, and quickly transfer it to an oil tank after taking it out. The oil temperature is 80°C, and the storage time is 1200 minutes. min; take it out and carry out pre-st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com