Sizing and rolling process of thick-walled seamless steel pipe by two-roller cross-rolling mill

A seamless steel pipe and skew rolling mill technology, applied in metal rolling, rolling force/roll gap control, etc., can solve the problems of complicated equipment and equipment, difficult to popularize, outward folding, etc., achieve high geometric dimensional accuracy, and be beneficial to product prices. , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

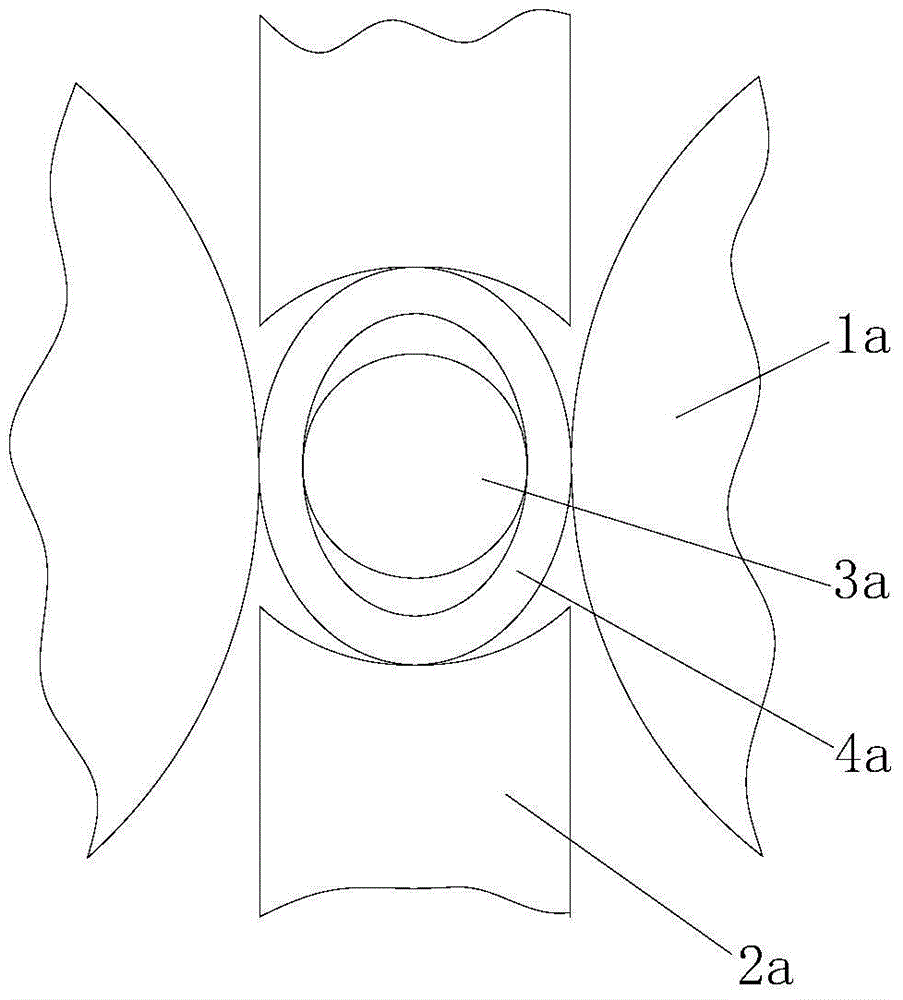

[0033] Example 1 The sizing process of thick-walled seamless steel pipes using a two-roll skew rolling mill

[0034] 1) If the outer diameter of the finished steel pipe to be obtained is 610mm, then adjust the roll 1 roll spacing of the two-roll skew rolling mill so that the roll 1 roll spacing is 616mm (610mm*1.01 times) the outer diameter of the finished steel pipe;

[0035] Adjust the guide disc distance of the two-roll skew rolling mill so that the guide disc distance is 628mm (616mm*1.02 times) of the roll distance of roll 1;

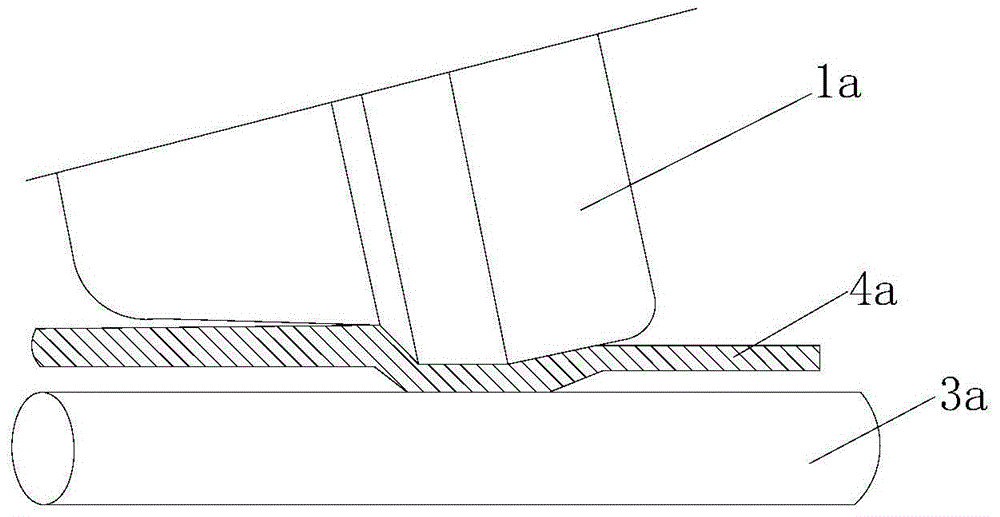

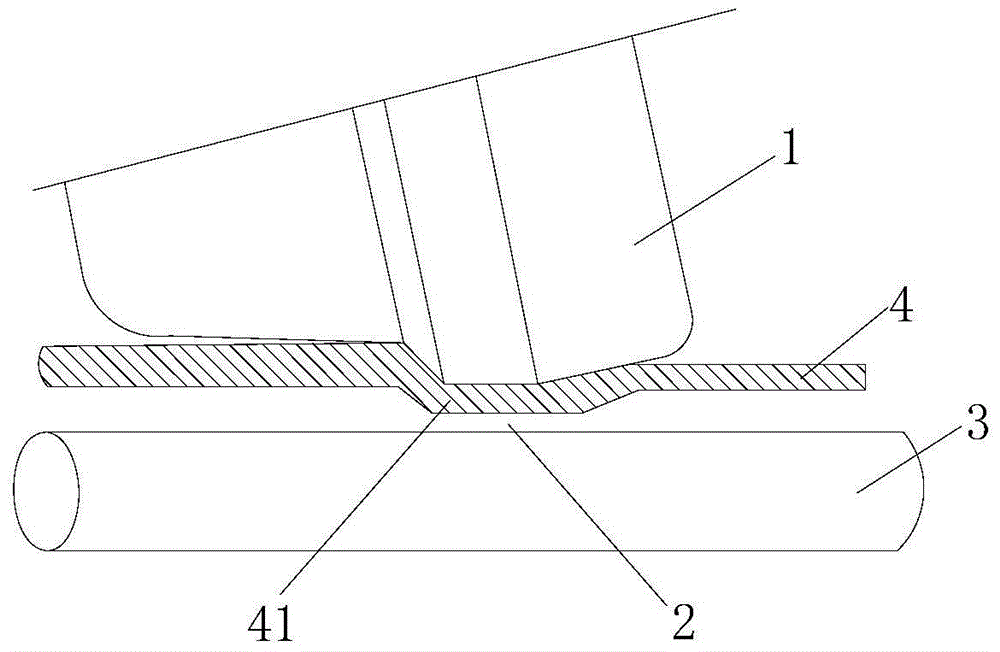

[0036] 2) Set the blank pipe 4 on the sizing mandrel 3 of the two-roll skew rolling mill, and carry out sizing rolling under the action of the roll 1 and the guide plate to obtain a thick-walled seamless steel pipe. The thickness of the thick-walled seamless steel pipe is The wall thickness is 120mm;

[0037] During sizing and rolling, the part of the blank pipe 4 that is in contact with the roll 1 is the rolling section 41, and there is always a ...

Embodiment 2

[0040] Embodiment 2 Rolling process of thick-walled seamless steel pipe

[0041] It includes a heating process, a piercing process, a wall reduction process and a sizing process in sequence, and the wall reduction process is carried out by a two-roll skew rolling mill.

[0042] The sizing process includes:

[0043] 1) If the outer diameter of the finished steel pipe is to be 660mm, then adjust the roll 1 roll distance of the two-roll skew rolling mill used during the wall reduction process so that the roll 1 roll distance is 1.01 times the outer diameter of the finished steel pipe;

[0044] Adjust the guide disc distance of the two-roll skew rolling mill so that the guide disc distance is 1.02 times the distance of roll 1;

[0045] 2) Replace the mandrel used in the wall-reducing process of the two-roll skew rolling mill with the sizing mandrel 3, and set the 4 sets of waste tubes obtained after the wall-reducing process on the sizing mandrel 3, and place them on the sizing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com