Organic carrier used for solar cell silver paste and preparation method for organic carrier

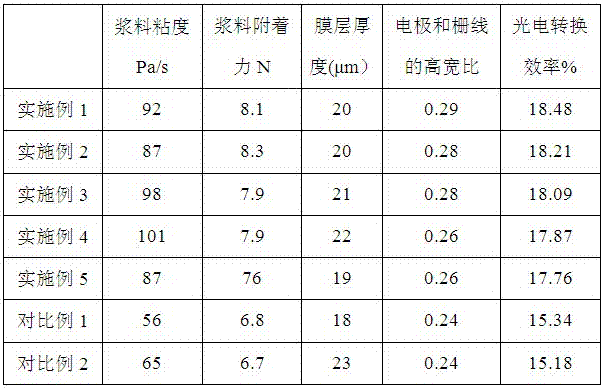

A technology of solar cells and organic carriers, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. The problems of small height and width of electrodes and gate lines can achieve the effect of excellent transfer, excellent transfer characteristics, and high aspect ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a kind of preparation method of the organic carrier for solar cell silver paste, comprising the following steps:

[0032] (1) Uniformly disperse the thickener and cationic surfactant in part of the organic solvent in an oil bath, the temperature of the oil bath is 100~160°C;

[0033](2) Evenly disperse the glass powder and hydrogenated castor oil in the remaining organic solvent, and disperse it by ultrasonic, the ultrasonic power is 300~600W, and the ultrasonic time is 5~45min;

[0034] (3) Add the mixing system of step (1) into the mixing system of step (2), add the coupling agent and stir evenly, then place it under the ultraviolet lamp for 1~10h;

[0035] (4) Grinding the reaction product in step (3), and passing through a 400-600 mesh sieve to obtain an organic carrier for solar cell silver paste.

[0036] According to the present invention, further, the mixing of the thickener and the cationic surfactant in the solvent in the s...

Embodiment 1

[0038] An organic vehicle for solar cell silver paste comprises the following parts by weight: 80 parts of DBE, 12 parts of glass powder, 1.2 parts of hydrogenated castor oil modified by polyamide, 5 parts of ethyl cellulose, 5 parts of rosin modified resin, dioxane 0.3 parts of ammonium methyl ethanolamine methyl sulfate, 5 parts of isopropyl tris(dioctyl phosphate acyloxy) titanate, 3 parts of paraffin wax, and 8 parts of ethylene glycol.

[0039] The preparation method of organic carrier for described solar cell silver paste, comprises the following steps:

[0040] (1) Evenly disperse ethyl cellulose, rosin modified resin, ammonium dialkylethanolamine methyl methylsulfate in 30 parts of DBE and stir in an oil bath, the temperature of the oil bath is 120°C, and the The rotating speed of stirring and mixing is 500 rpm, and the time of stirring and mixing is 10min;

[0041] (2) Evenly disperse the glass powder and polyamide-modified hydrogenated castor oil in 50 parts of DBE,...

Embodiment 2

[0045] An organic vehicle for solar cell silver paste includes 70 parts by weight of terpineol, 15 parts of glass powder, 1 part of polyamide-modified hydrogenated castor oil, 15 parts of ethyl cellulose, and 0.1 parts of trialkylammonium chloride Parts, 6 parts of vinyltrimethoxysilane, 2 parts of paraffin, 5 parts of ethylene glycol.

[0046] The preparation method of organic carrier for described solar cell silver paste, comprises the following steps:

[0047] (1) Evenly disperse ethyl cellulose and trialkylammonium chloride in 30 parts of terpineol and stir in an oil bath, the temperature of the oil bath is 100°C, and the stirring speed is 500 rpm / minute, the time of the stirring and mixing is 5min;

[0048] (2) Evenly disperse glass powder and polyamide-modified hydrogenated castor oil in 40 parts of terpineol, and ultrasonically disperse with ultrasonic power of 300W and ultrasonic time of 45 minutes;

[0049] (3) Add the mixed system of step (1) into the mixed syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com