Alkali-free liquid accelerator and preparation method and application thereof

A technology of quick-setting agent and liquid, applied in the field of building materials, can solve the problems of large construction dust, strength shrinkage, health hazards of construction workers, etc., and achieve the effects of small strength loss in the later stage, no loss of compressive strength, and fast and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

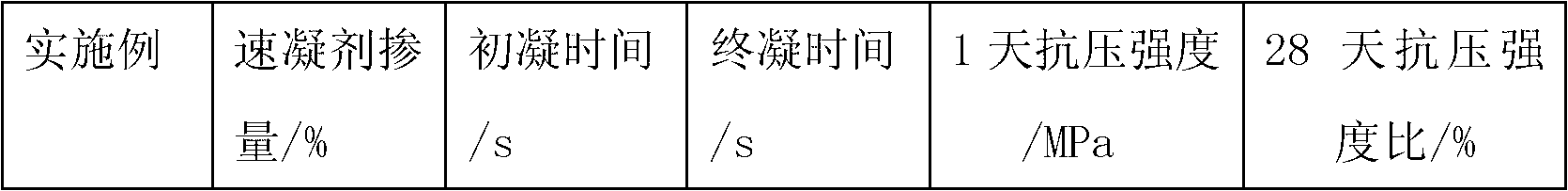

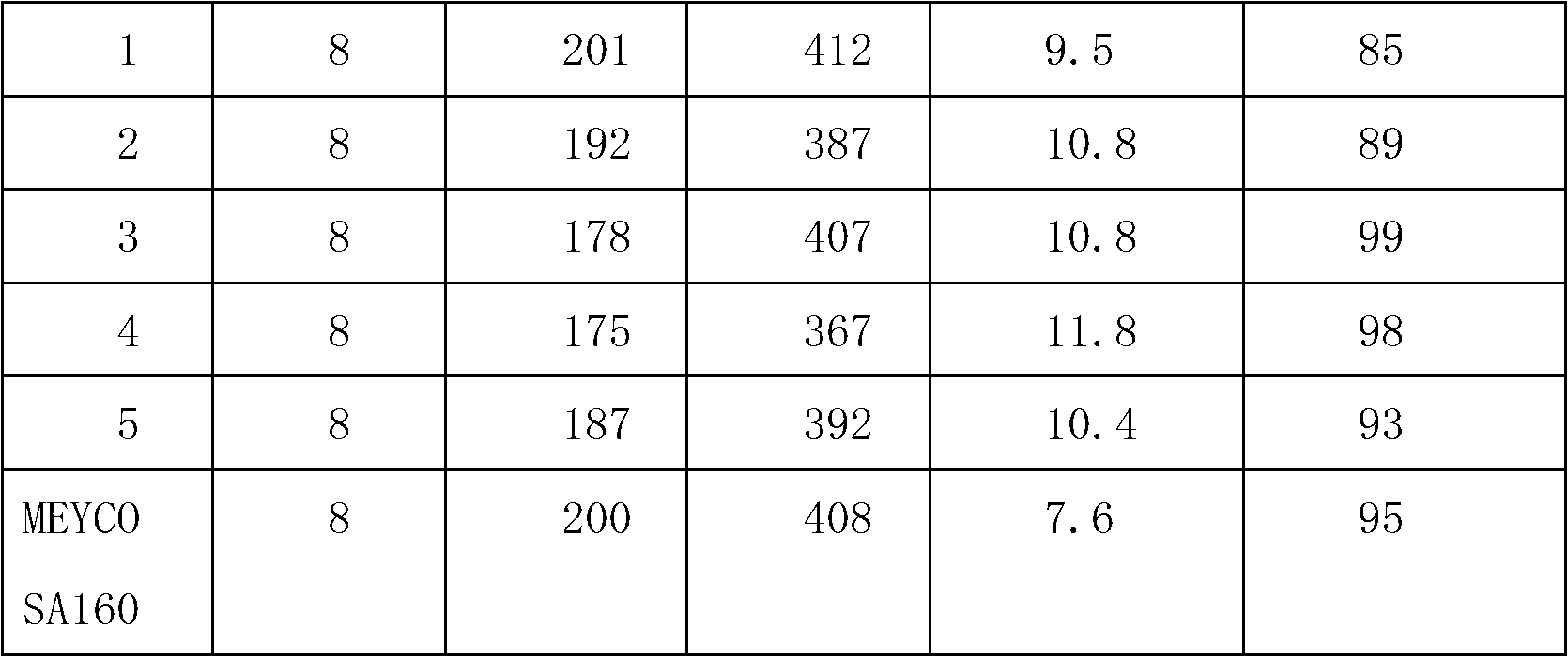

Examples

Embodiment 1

[0023] The preparation method of an alkali-free liquid quick-setting agent comprises the following raw materials and their mass percentages: 50% of aluminum sulfate, 1% of citric acid, 7% of diethanolamine, 10% of glycerin, 1% of nitric acid and 31% of water.

Embodiment 2

[0025] A preparation method of an alkali-free liquid quick-setting agent, the raw materials used and their mass percentages are composed of: 55% of aluminum sulfate, 1% of citric acid, 10% of triethanolamine, 7% of diethylene glycol, 1% of phosphoric acid, and 26% of water .

Embodiment 3

[0027] The preparation method of a non-alkali liquid quick-setting agent comprises the following raw materials and their mass percentages: 45% of aluminum sulfate, 2% of lactic acid, 5% of triethanolamine, 5% of ethylene glycol, 2% of sulfuric acid and 41% of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com