Liquid accelerator and preparation method thereof

A technology of quick-setting agent and liquid, which is applied in the field of liquid accelerator and its preparation, which can solve the problems of fast liquid accelerator preparation method and lack of setting time, so as to improve the final setting time and compressive strength, and the synthesis process is simple , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

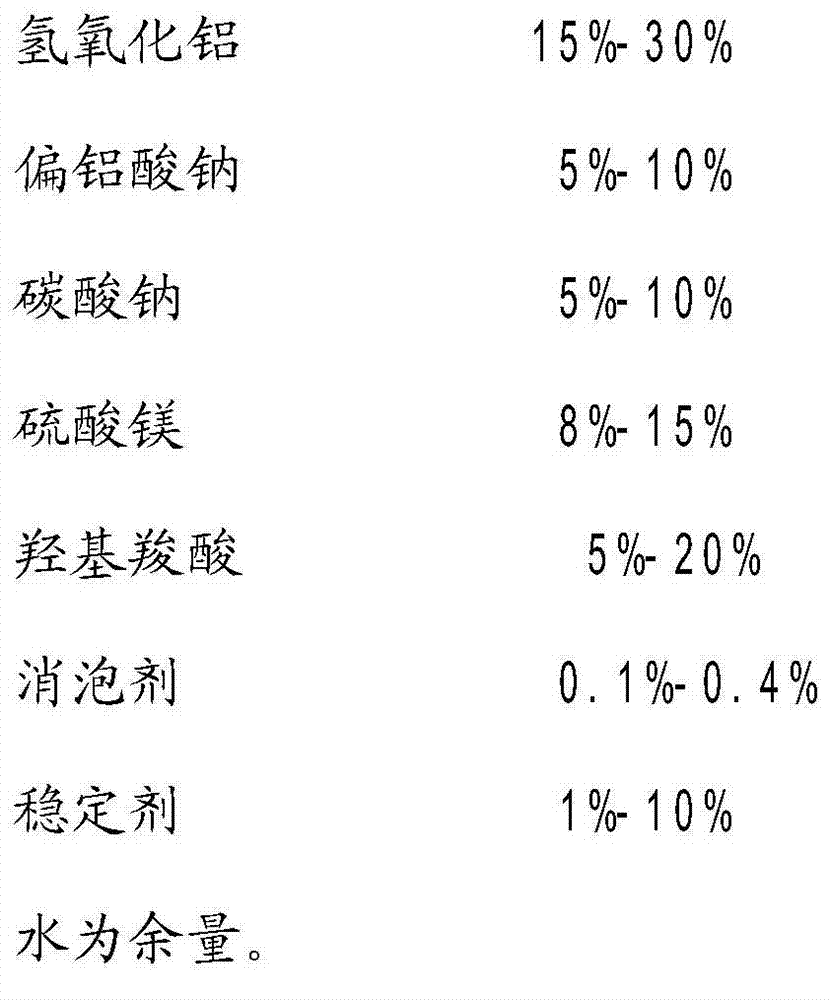

[0017] The invention provides a liquid quick-setting agent, and the quick-setting agent is composed of the following components by mass percentage:

[0018]

[0019]

[0020] The defoamer is selected from the combination of glycerin fatty acid ester and glycerin.

[0021] The hydroxycarboxylic acid is selected from five combinations of citric acid, salicylic acid, lactic acid, formic acid and oxalic acid.

[0022] The stabilizer is selected from the combination of urea, formaldehyde and polyacrylamide.

[0023] The preparation method of liquid accelerator of the present invention comprises the following steps:

[0024] Dissolve aluminum sulfate, aluminum hydroxide, sodium carbonate, and magnesium sulfate in hot water. After the dissolution is complete, add hydroxycarboxylic acid slowly under stirring. After the dissolution is complete, add defoamer and stabilizer in sequence. to room temperature to prepare the product.

[0025] The stirring rate during the stirring is...

Embodiment 2

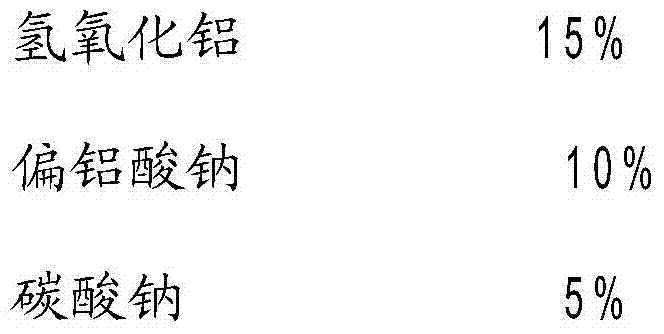

[0028] The difference between embodiment 2 and embodiment 1 is: the present invention provides a kind of liquid quick-setting agent, and described quick-setting agent is made up of following components by mass percentage:

[0029]

[0030] The defoamer is glycerin fatty acid ester.

[0031] The hydroxycarboxylic acid is selected from a combination of citric acid and salicylic acid.

[0032] The stabilizer is selected from five combinations of urea, formaldehyde, polyacrylamide, diethanolamine and triethanolamine.

[0033] In the preparation method of the liquid quick-setting agent according to the present invention, the stirring rate during the stirring is 700r / min.

Embodiment 3

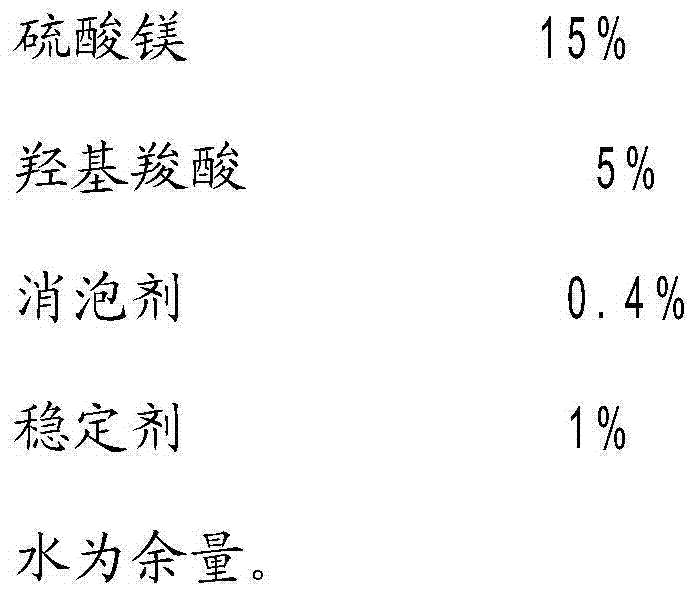

[0035] The difference between embodiment 3 and embodiment 1 is: the present invention provides a kind of liquid quick-setting agent, and described quick-setting agent is made up of following components by mass percentage:

[0036]

[0037]

[0038] The defoamer is glycerin.

[0039] The hydroxycarboxylic acid is selected from one or a combination of citric acid, salicylic acid, lactic acid, formic acid and oxalic acid.

[0040] The stabilizer is selected from the combination of diethanolamine and triethanolamine. In the preparation method of the liquid quick-setting agent according to the present invention, the stirring rate during the stirring is 900r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com