High-tension board forming device

A forming device and high-tension technology, which is applied in the field of cold stamping equipment and auto parts forming equipment, can solve the problems of difficult step surface shaping, large material springback, and poor drawing effect, so as to reduce springback and reduce The effect of sheet metal rebound and internal stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

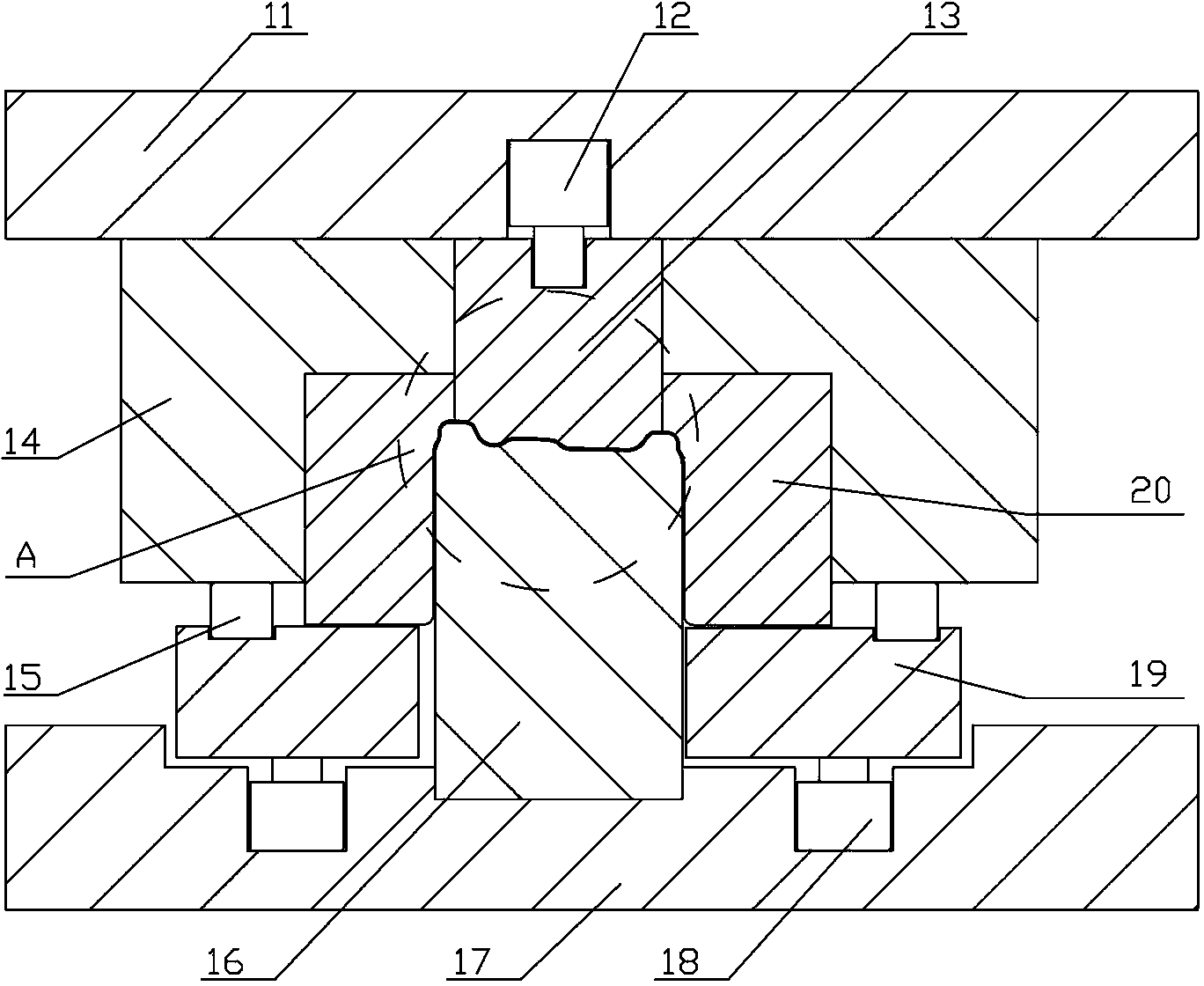

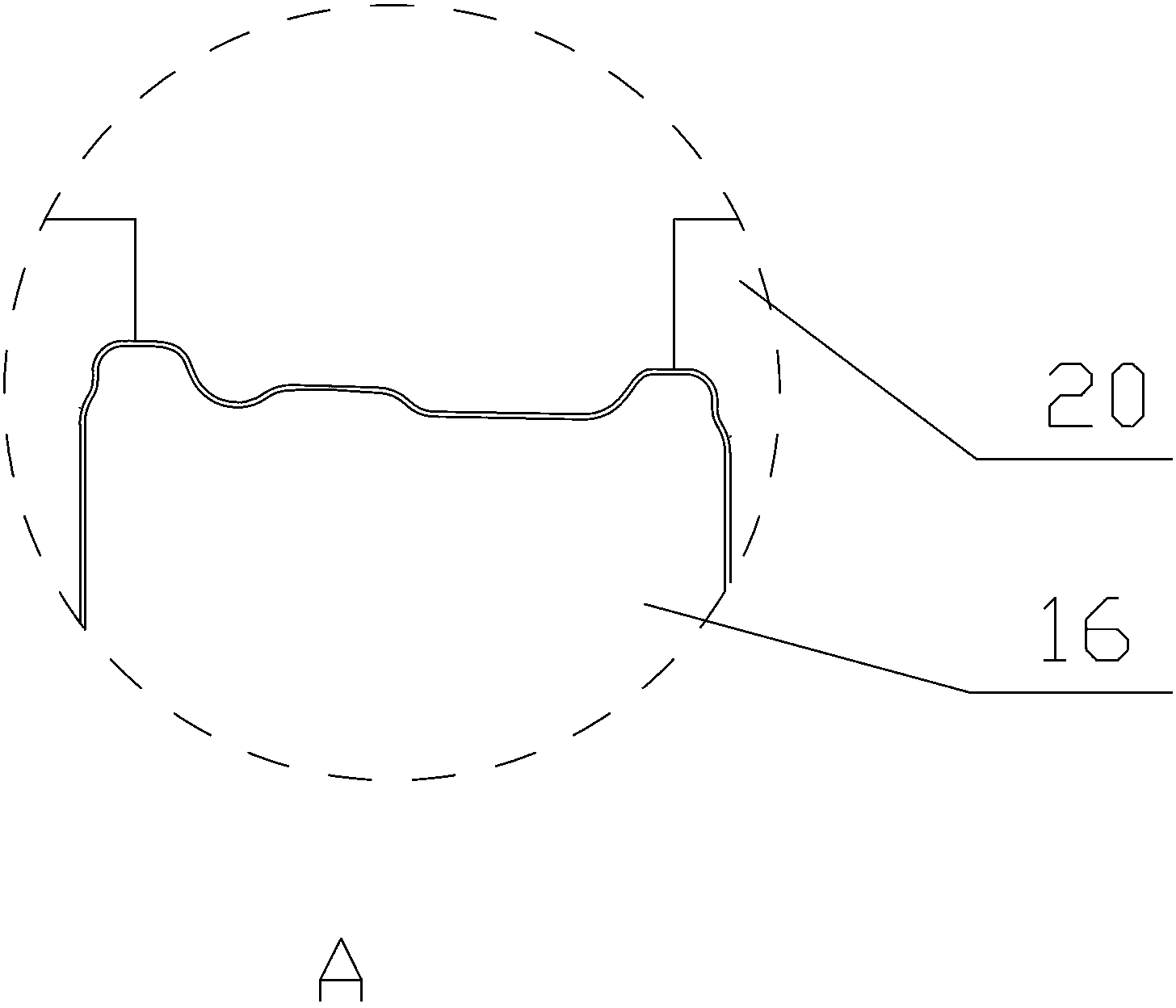

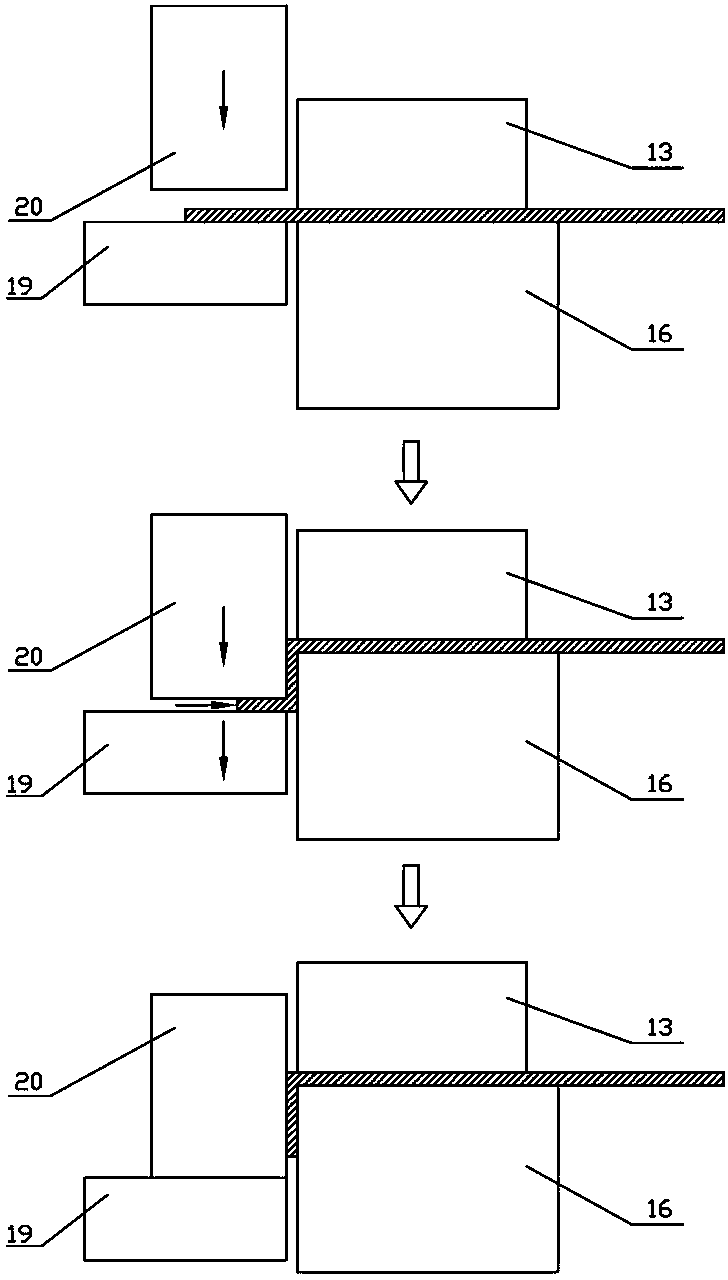

[0038] Such as Figure 1 to Figure 12As shown, a high tension plate forming device is characterized in that: a high tension plate forming device is characterized in that: comprising an upper die base 11, an upper die pressing plate 13, an upper die forming punch 20, a lower die forming male 16. The lower mold base 17 and the lower mold pressing plate 19, wherein, the above-mentioned upper mold pressing plate 13 is connected with the upper mold base 11, and the upper mold forming punches 20 are arranged on both sides of the upper mold pressing plate 13; the above-mentioned lower mold pressing plate 19 is connected with the lower mold base 17, and the middle of the lower mold pressing plate 19 is provided with the lower mold forming male 16; The two inner sidewalls are provided with grooves 22 corresponding to the convex hulls; when bending, the upper mold pressing plate 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com