Method for improving performance uniformity of steel roll of Ti microalloyed high strength machinery

A technology of mechanical steel and micro-alloying, which is applied in the direction of temperature control, etc., can solve the problem that there is no steel coil inner and outer ring strength properties. Effective improvement measures are proposed, and the performance of the inner and outer rings of the steel coil and the uniformity of the width direction are studied. and elaboration, without paying attention to the performance fluctuation of high-strength mechanical steel, to achieve the effect of improving the comprehensive yield, improving the uniformity of properties, and improving the strength and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

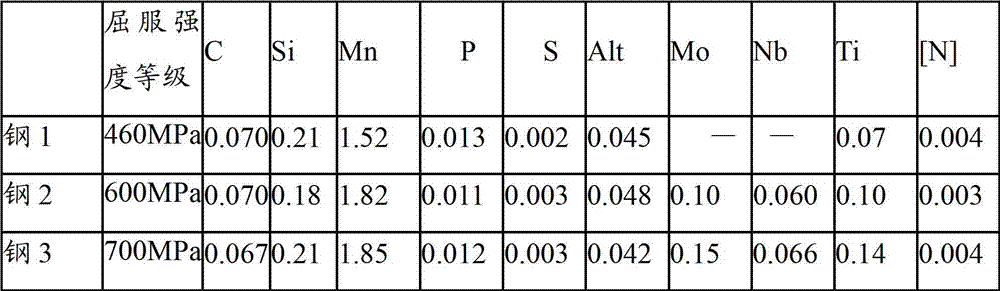

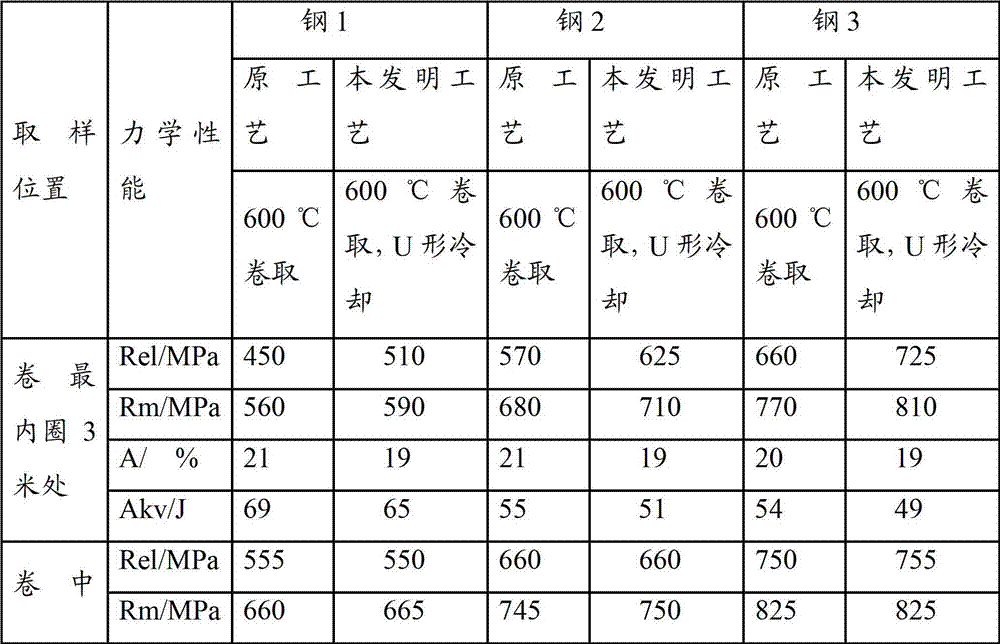

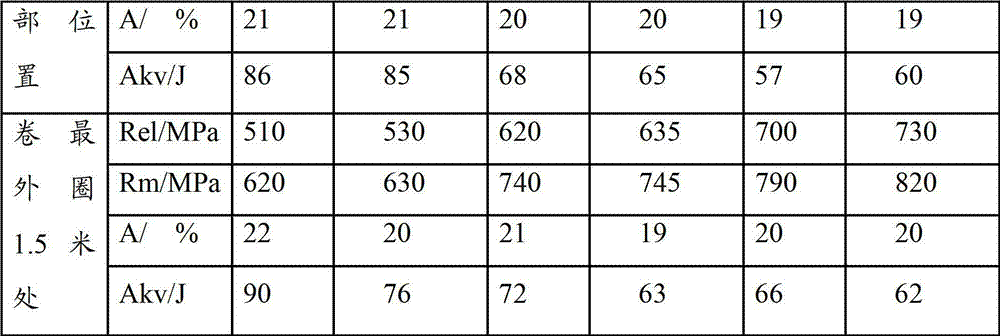

[0030]This embodiment provides a method for improving the uniformity of the coil performance of Ti microalloyed high-strength mechanical steel. By changing the shape of the coiling curve and using U-shaped cooling, the coiling temperature of the innermost 15-meter circle of the coil is increased by 15- At 20°C, the coiling temperature of the 15-meter outermost circle of the coil increases by 10-15°C. In this embodiment, the coiling temperature setting value of the original process is 600°C. In the present invention, the coiling temperature is controlled at 620°C within 15 meters of the inner circle of the steel coil, and the coiling temperature is controlled at 615°C within 15 meters of the outermost circle of the steel coil. ℃ control. Then samples were taken at 3 meters from the inner circle of the coil, at the normal position in the middle of the steel coil, and at 1.5 meters from the outermost circle of the coil for mechanical performance inspection. The impact sample siz...

Embodiment 2

[0038] A method for improving the uniformity of Ti microalloyed high-strength mechanical steel coil performance provided by this embodiment is to use an induction heater to heat the intermediate billet before finish rolling, so that the temperature of the heated intermediate billet is higher than that of the rough rolled billet. The ending temperature is 0-150°C higher to make up for the temperature drop caused by excessive heat dissipation at the edge of the thin-gauge intermediate billet, thereby improving the uniformity of the final product along the transverse direction. The steel type selected in this example is a Ti microalloyed high-strength steel with a yield strength of 700 MPa, and the Ti content is 0.12%. The specific chemical composition is shown in Table 3. In the production process, the rough rolling finish temperature is set at 1080°C. According to the method of the present invention, the edge portion of the intermediate billet is induction heated before finishin...

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that in this embodiment, the coiling temperature is controlled at 615° C. within 15 meters of the inner ring of the steel coil, and 610° C. within 15 meters of the outermost ring of the steel coil. Other places are completely consistent with Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Longitudinal yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com