Technique for manufacturing 150-400mm thick carbon constructional steel plate by using continuous casting slabs

A carbon structure and slab technology, applied in the field of metal materials, can solve the problems of low production efficiency, low yield, and high energy consumption, and achieve the effects of high production efficiency, low cost, and increased heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

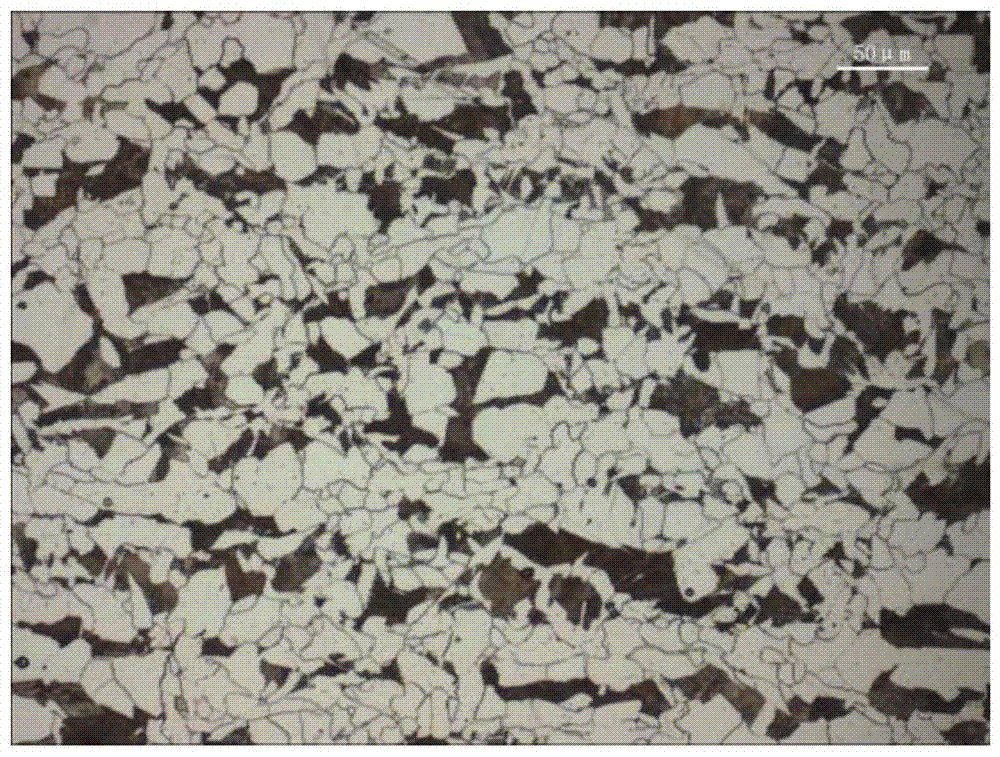

Image

Examples

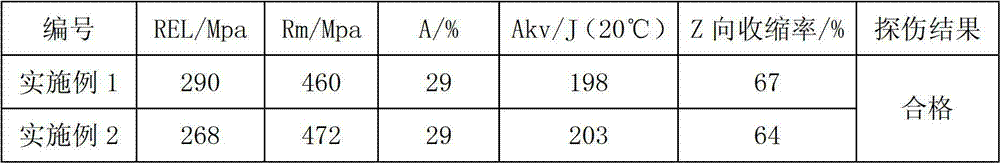

Embodiment 1

[0031] Embodiment 1: Production of 200mm thick Q235B steel plate:

[0032] 1) High-purity molten steel is smelted. After the molten steel is smelted in a converter, LF+RH double refining is carried out. LF refining fully removes inclusions and desulfurization. RH vacuum treatment maintains a vacuum degree of 100Pa for 14 minutes. After refining, the gas in the molten steel [O] 13ppm, [H]2ppm.

[0033] 2) The continuous casting process of molten steel adopts full protection pouring, and uses electromagnetic stirring, pouring at a constant speed to produce continuous casting slabs with a thickness of 250mm and the same fixed length. The analysis results of the melting composition are as follows:

[0034] Table 1 Example 1 Continuous Casting Slab Chemical Composition

[0035] chemical composition C Si mn P S Contentwt% 0.20 0.25 1.10 0.016 0.004

[0036] 3) The two 250mm thick continuous casting slabs produced are processed by milling machine to r...

Embodiment 2

[0047] Embodiment 2: Production of 200mm thick Q235B steel plate:

[0048] 1) High-purity molten steel is smelted. After the molten steel is smelted in a converter, LF+RH double refining is carried out. LF refining fully removes inclusions and desulfurization. RH vacuum treatment maintains a vacuum degree of 100Pa for 16 minutes. After refining, the gas in the molten steel [O] 12ppm, [H]2.1ppm.

[0049] 2) The continuous casting process of molten steel adopts full protection pouring, and uses electromagnetic stirring, pouring at a constant speed to produce continuous casting slabs with a thickness of 250mm and the same fixed length. The analysis results of the melting composition are shown in Table 2:

[0050] Table 2 Example 2 Continuous Casting Slab Chemical Composition

[0051] chemical composition C Si mn P S Contentwt% 0.18 0.30 1.15 0.010 0.008

[0052] 3) The two 250mm thick continuous casting slabs produced are processed by milling mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com