Steel for quenched and tempered coiled tubing, hot rolled steel strip, steel tube and manufacturing methods of hot rolled steel strip and steel tube

A manufacturing method and oil pipe technology, which are applied in the fields of steel strips, steel grades, steel pipes and their manufacturing, can solve the problems of difficulty in developing ultra-high strength coiled tubing, large residual stress in welded parts, and decreased fatigue life of welded seams, etc. Permeability and tempering stability, good fatigue life and corrosion resistance, the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1-2

[0080] Table 1 lists the mass percentage of each chemical element in the quenched and tempered coiled tubing steel of Examples 1-6 and the steel of Comparative Examples 1-2.

[0081] Table 1. (wt%, the balance is Fe and other unavoidable impurities except P and S)

[0082]

[0083]

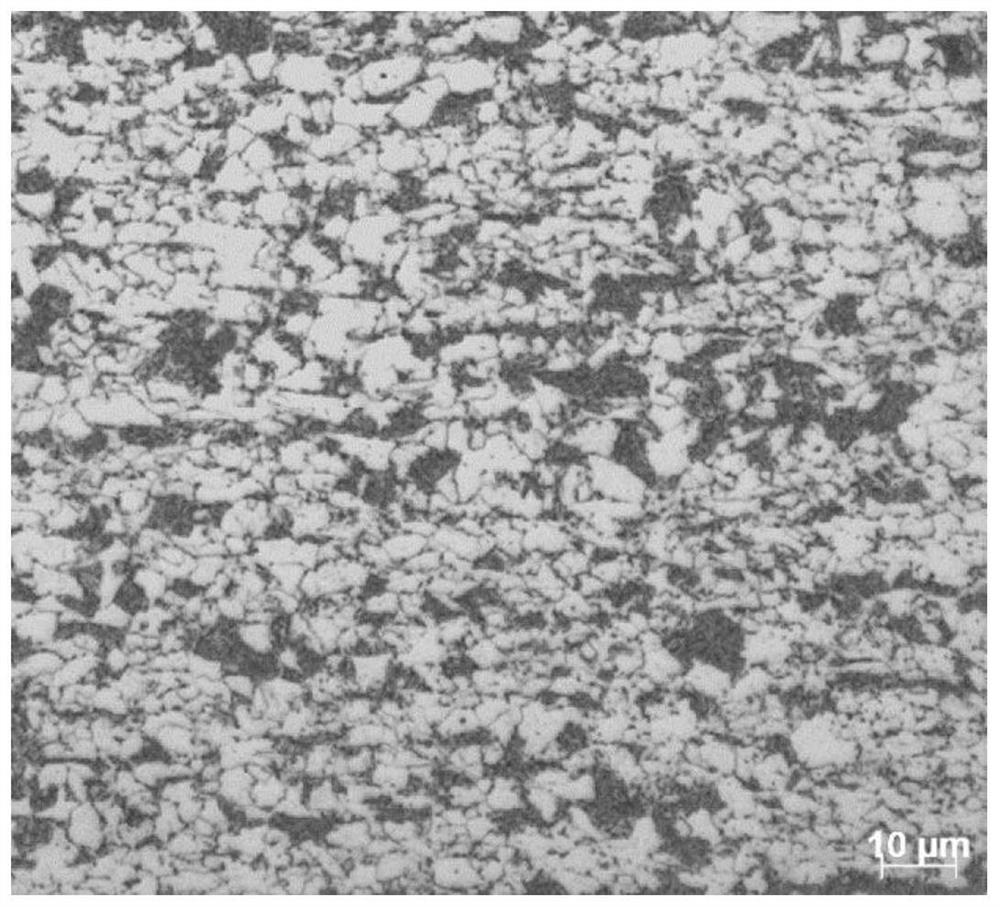

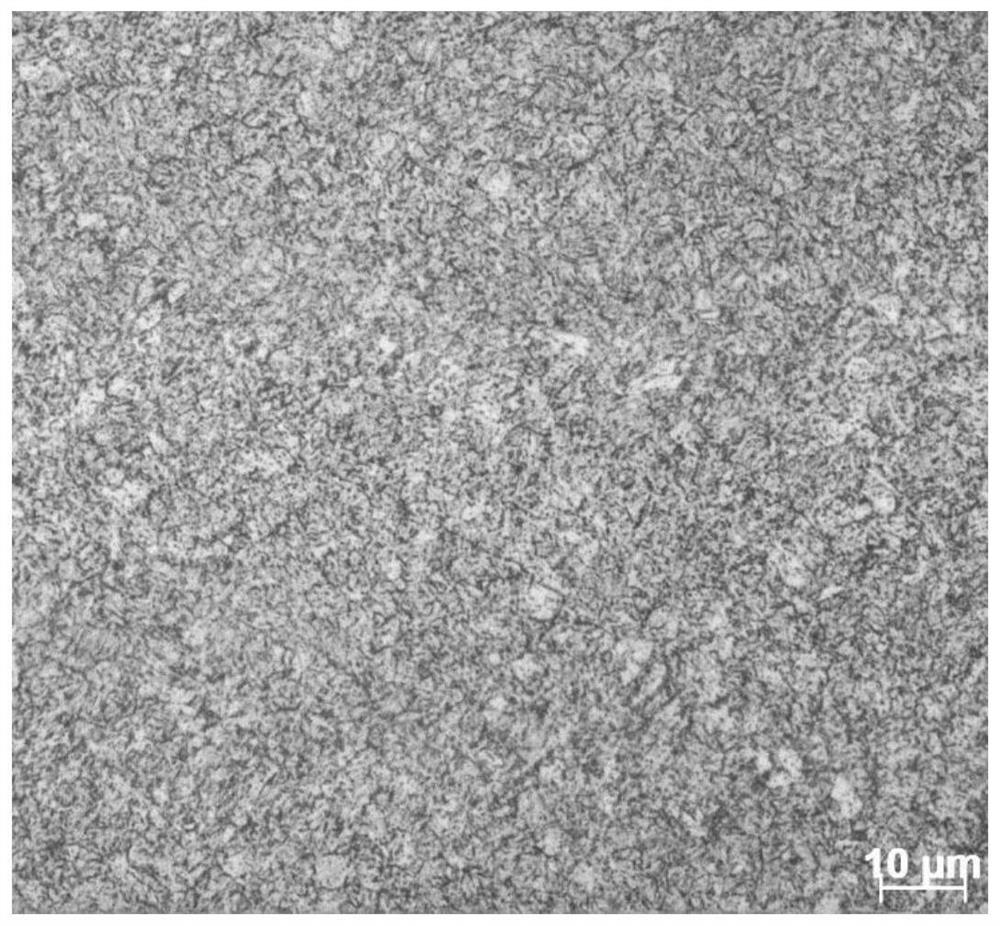

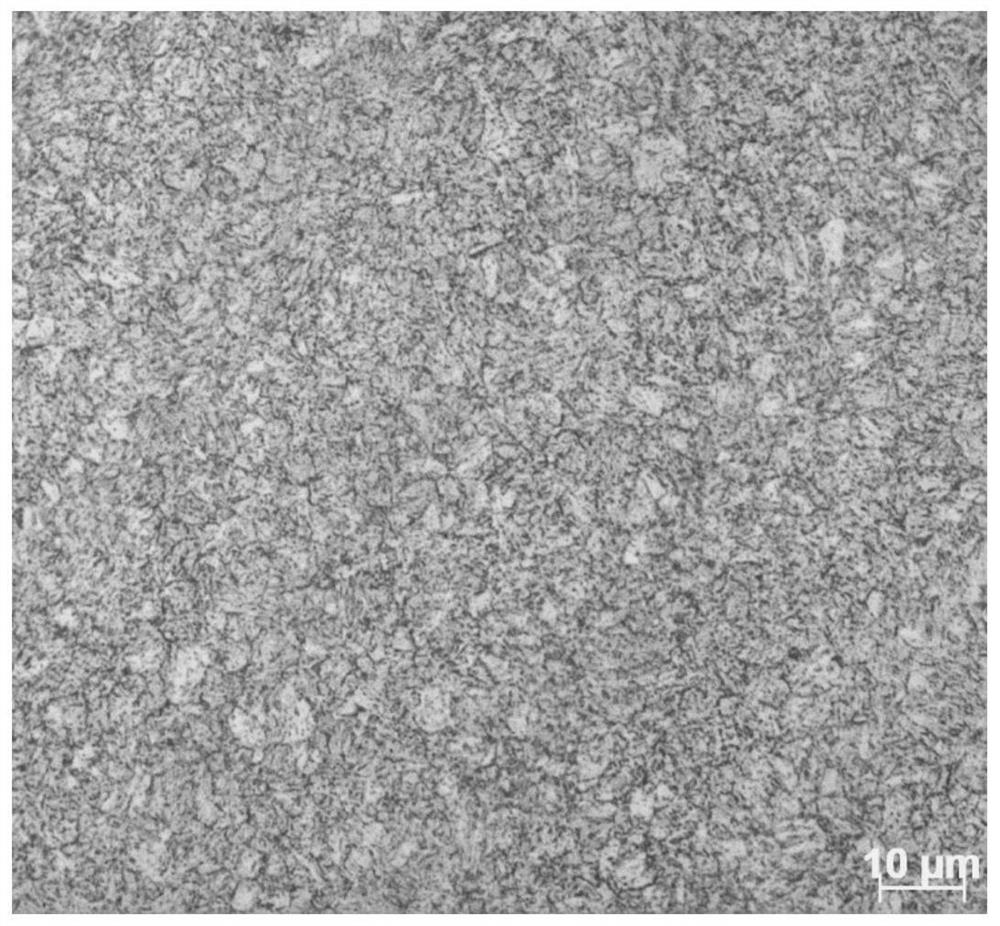

[0084] The steel for quenched and tempered coiled tubing in Example 1-6 of the present invention and the steel in Comparative Example 1-2 can be correspondingly made corresponding hot-rolled steel strips, and the following examples 1-1 to 6- 1 represents the hot-rolled steel strips prepared by using the steels for quenched and tempered coiled tubing in Examples 1-6 and the steels in Comparative Examples 1-2, respectively.

[0085] The hot-rolled steel strip of embodiment 1-1 to embodiment 6-1 and the hot-rolled steel strip of comparative example 1-1 and comparative example 2-1 all adopt the following steps to make:

[0086] (1) Smelting and continuous casting: In the smelting step, electric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com