Method for calculating ultrahigh-cycle fatigue crack initiation time

A fatigue crack and time calculation technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the estimated contribution of remaining life is not direct enough, coupling effect is not considered, and the crack growth rate is not constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

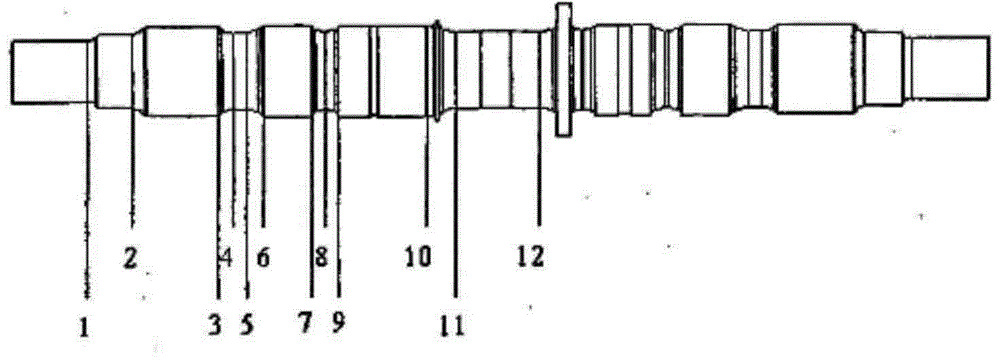

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

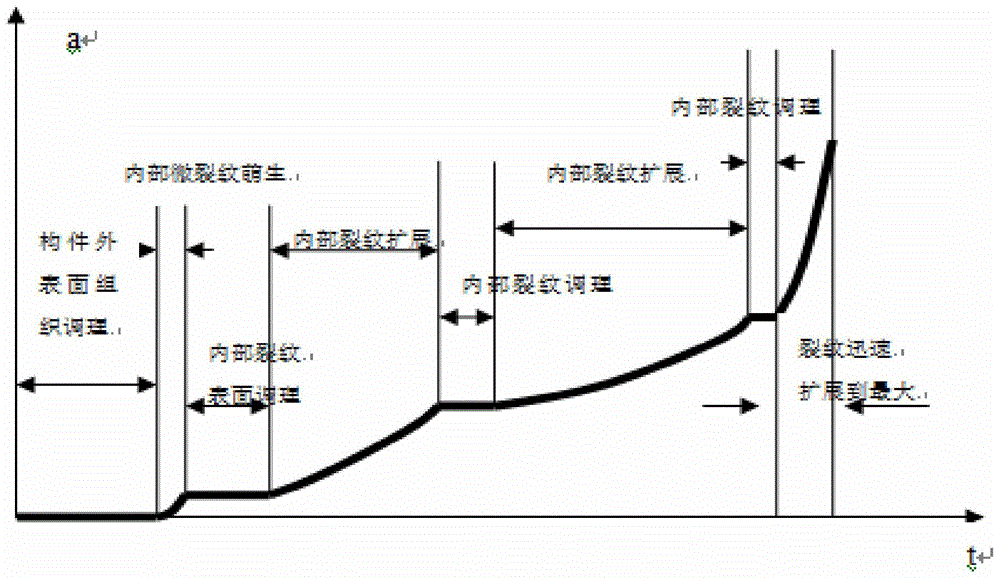

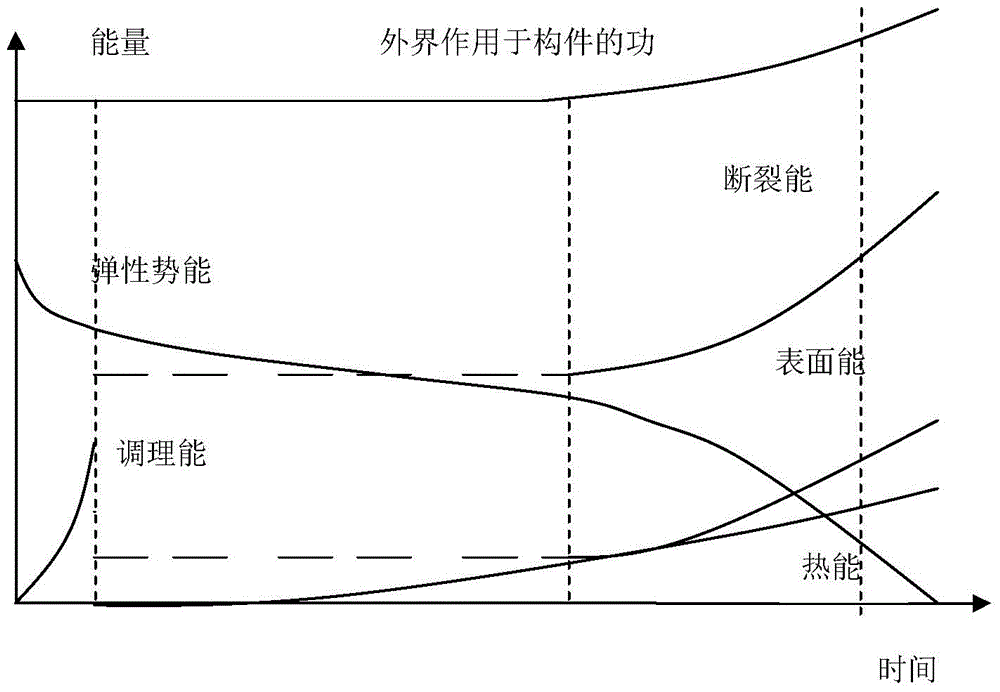

[0048] The internal structure of the material is not uniform, and the environment of each lattice is not the same. Under the alternating load, the component bears the force, the component undergoes slight deformation, and absorbs a large proportion of energy in the form of potential energy. Stress concentration at some places, dislocations occur in some minority lattices, molecular spacing changes, local temperature rises, thermal expansion occurs, and thermal stress occurs. At the same time, due to local temperature rises, the mechanical properties of materials in local areas change, yield strength and cracks The threshold value is getting smaller, resulting in very small cracks; the generation of cracks requires the formation of surface energy on the one hand, and on the other hand, the generation of strain, the formation of potentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com