Guide rail of compound type and a method for manufacturing such a rail

A compound type, guide rail technology, applied in the direction of rails, rails, transportation and packaging, etc., can solve problems such as noise, difficulty in material forming, and click sound of guide rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

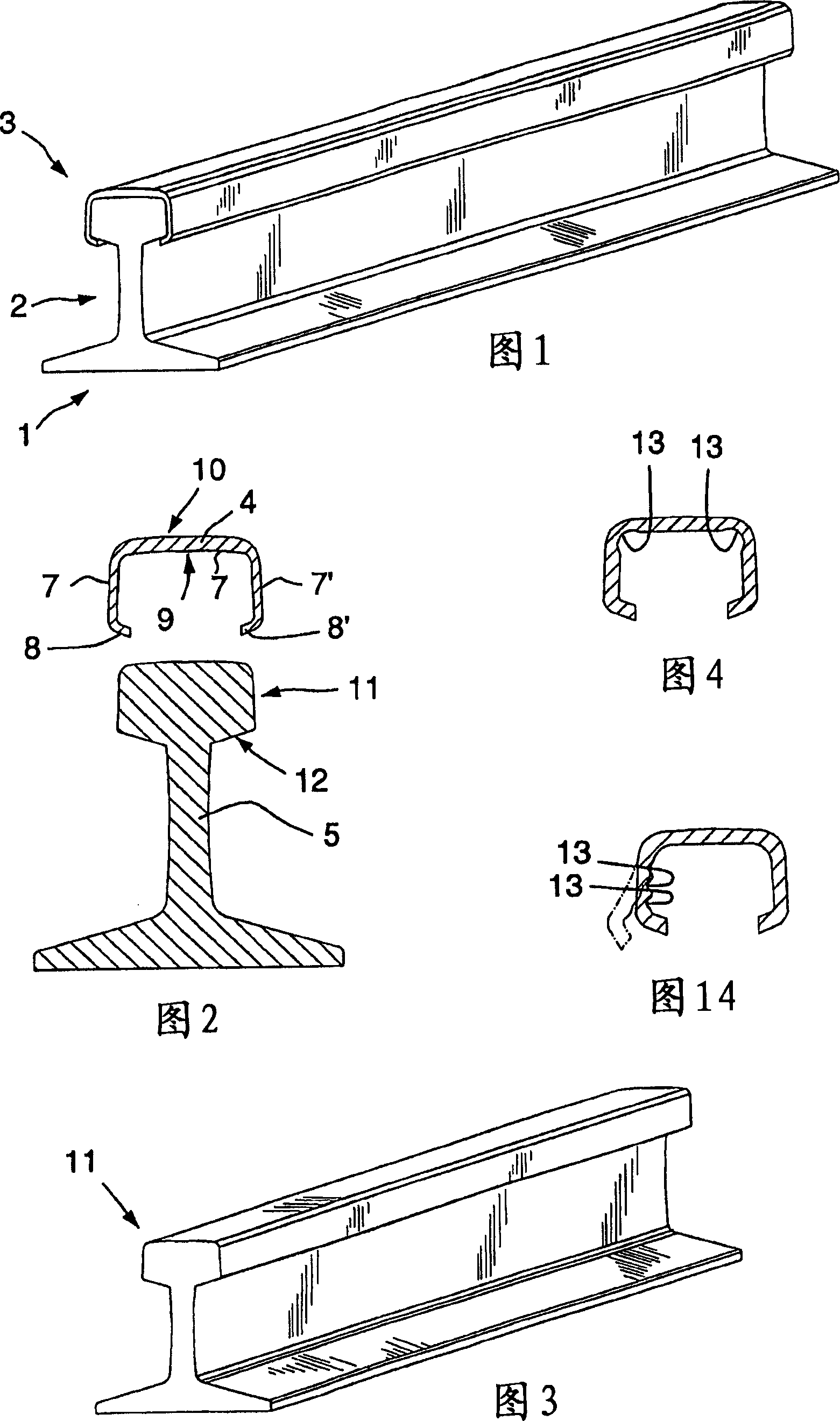

[0024] FIG. 1 illustrates an embodiment of the guide rail according to the invention, which in this case constitutes a so-called railway track generally comprising a base 1 , a web 2 and a main part 3 .

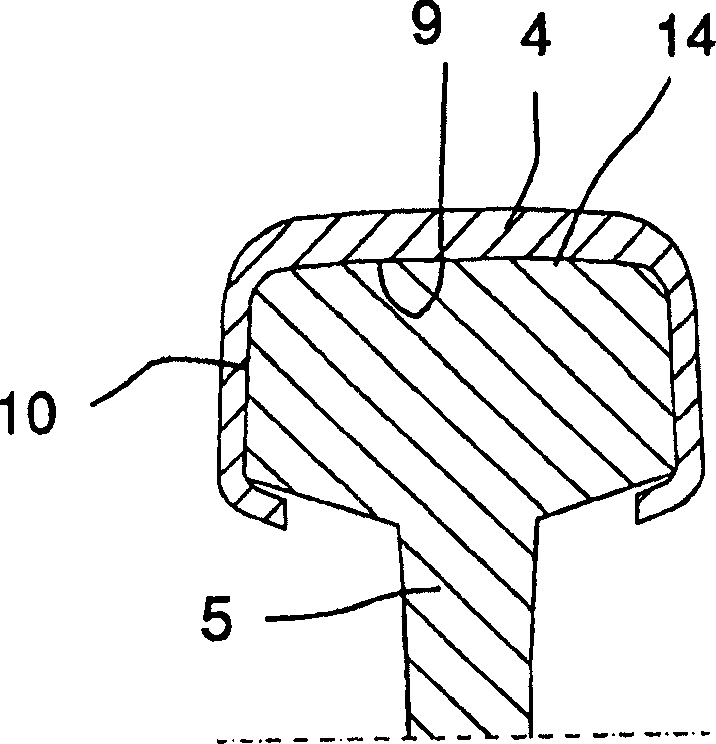

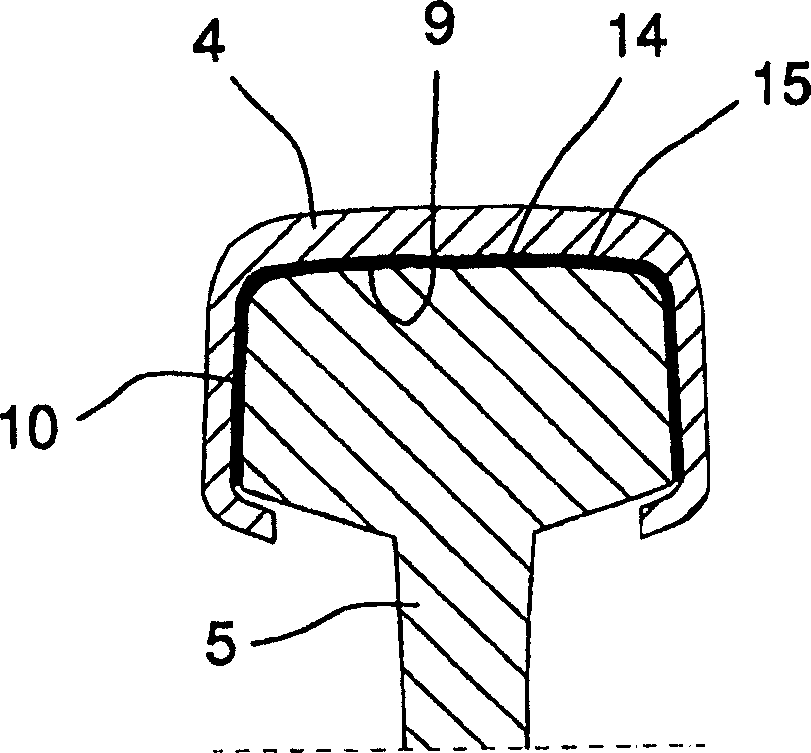

[0025] Referring to Figures 2 and 3, the guide rail of the present invention is mainly composed of two parts; a first part 4, which in this example consists of a single outer rail made of sheet metal of limited or relatively small thickness, and a second part 5, in the In this case it includes the bottom rail. The term bottom rail hereinafter denotes an element made of beams, rods or similar thick solid material which has been prepared to receive the outer rail 4 by a machining stage after rolling. In new manufacture, the bottom rail is initially given the required shape during a rolling process. Through said preparatory phase, the outer rail 4 and the base rail 5 are given a shape so that the relatively thin-walled outer rail 4 can be received without deformation and suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com