Straightening scheme of metal plate-belt roll type combination straightening machine

A metal strip and straightening machine technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems of reducing strip straightening quality, slippage, noise, etc. The effect of straight precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

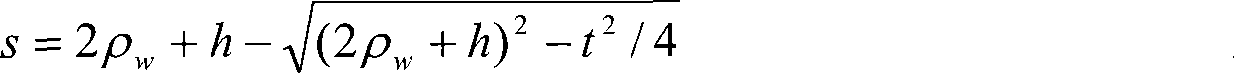

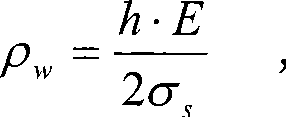

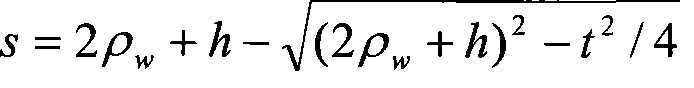

[0013] Now there is a metal strip with thickness h=400mm, modulus of elasticity E=210000Mpa, yield limit σ s = 400Mpa, take the roll distance t = 400mm of the large roller system of the roller-type combined straightening machine, and bring it into the formula ρ w = h · E 2 σ s and s = 2 ρ w + h - ( 2 ρ w + h ) 2 - t 2 / 4 , The reduction amount s = 2.4 mm was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com