A new type of compressor self-limiting exhaust valve plate, exhaust valve plate assembly, compressor

An exhaust valve plate and compressor technology, applied in the field of compressors, can solve the problems of increased compressor noise, high-speed impact of valve plates and baffles, and increased impact degree, so as to reduce the number of parts, simplify the assembly process, and eliminate noise. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

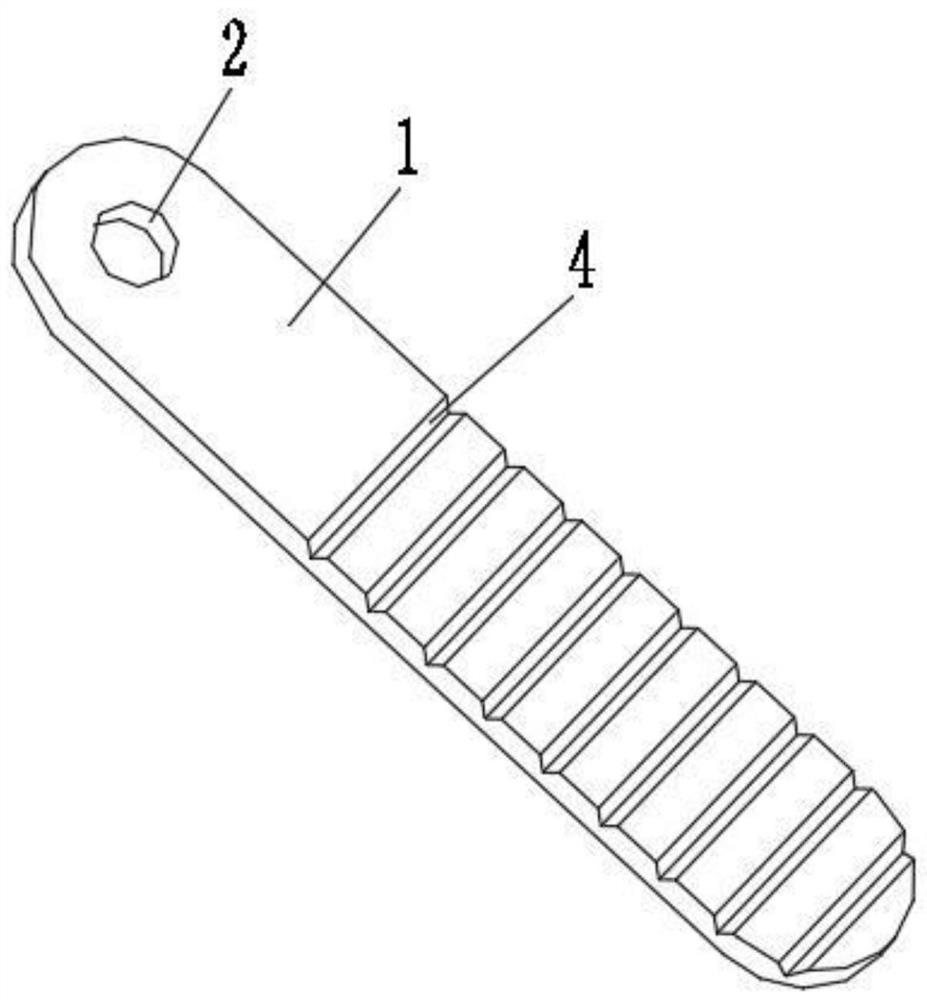

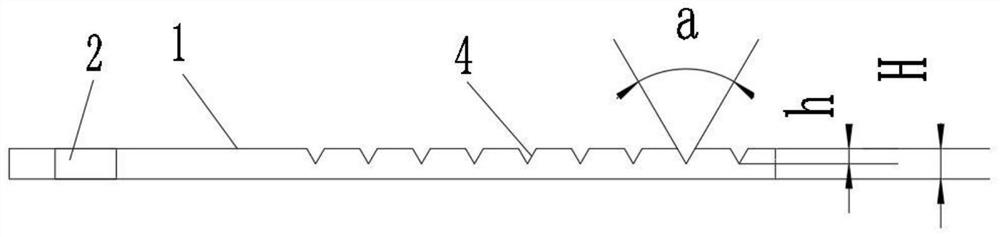

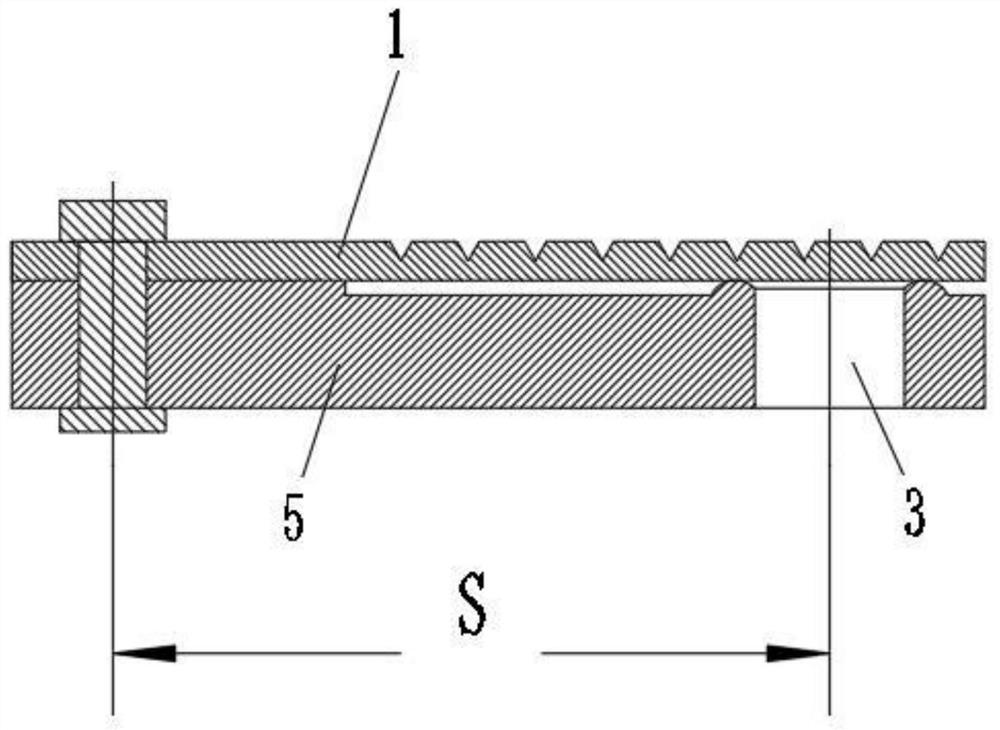

[0027] A new type of compressor self-limiting exhaust valve plate in this embodiment, such as Figure 1-4 As shown, including a valve plate 1, one end of the valve plate 1 is provided with a mounting hole 2 along the thickness direction of the valve plate 1, and the surface of the valve plate 1 facing away from the exhaust hole 3 is along the surface of the valve plate 1 There is at least one groove 4 crossing the valve plate 1 in the thickness direction. Install and fix the valve plate 1 on the valve seat 5 by opening an installation hole 2 along the thickness direction of the valve plate 1 at one end of the valve plate 1, and at the same time, through the surface of the valve plate 1 facing away from the exhaust hole 3 along the thickness of the valve plate 1 The groove 4 across the valve plate 1 is set in the direction of the compressor. When the compressor exhausts, the valve plate 1 is bent due to the impact of the gas, and the state of the valve plate 1 is determined by ...

Embodiment 2

[0035] This embodiment provides an exhaust valve assembly, such as Figure 1-4 As shown, the exhaust valve plate assembly uses the new self-limiting exhaust valve plate of the compressor described in Embodiment 1, and the valve plate 1 is fixed by opening a mounting hole 2 along the thickness direction of the valve plate 1 at one end of the valve plate 1. It is installed and fixed on the valve seat 5. At the same time, the groove 4 crossing the valve plate 1 is set on the surface of the valve plate 1 facing away from the exhaust hole 3 along the thickness direction of the valve plate 1. When the compressor exhausts, the valve plate 1 Bending occurs due to the impact of gas. At this time, the opening of the groove 4 will gradually decrease with the increase of the bending angle of the valve plate 1. When the bending angle of the valve plate 1 reaches a certain angle, the groove 4 will be completely closed, which can prevent the valve plate 1 continues to bend, so as to realize ...

Embodiment 3

[0038] This embodiment provides a compressor, which uses the exhaust valve plate assembly described in Embodiment 2, because the valve plate 1 is installed and fixed by opening an installation hole 2 at one end of the valve plate 1 along the thickness direction of the valve plate 1 On the valve seat 5, at the same time, by opening a groove 4 across the valve plate 1 along the thickness direction of the valve plate 1 on the surface of the valve plate 1 facing away from the exhaust hole 3, when the compressor is exhausted, the valve plate 1 will be exhausted due to gas At this time, the opening of the groove 4 will gradually decrease with the increase of the bending angle of the valve piece 1. When the bending angle of the valve piece 1 reaches a certain angle, the groove 4 will be completely closed, which can prevent the valve piece 1 from continuing to bend. Bending, so as to realize the automatic limit during the bending process of the valve piece 1, so the baffle can be remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com