Plastic partition splitting system and method of use

A technology of plastic clapboards and pallets, used in pile separation, thin material handling, object separation, etc., can solve the problems of human impact, low efficiency, high labor intensity, etc., achieve reliable fixation, save human resources, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

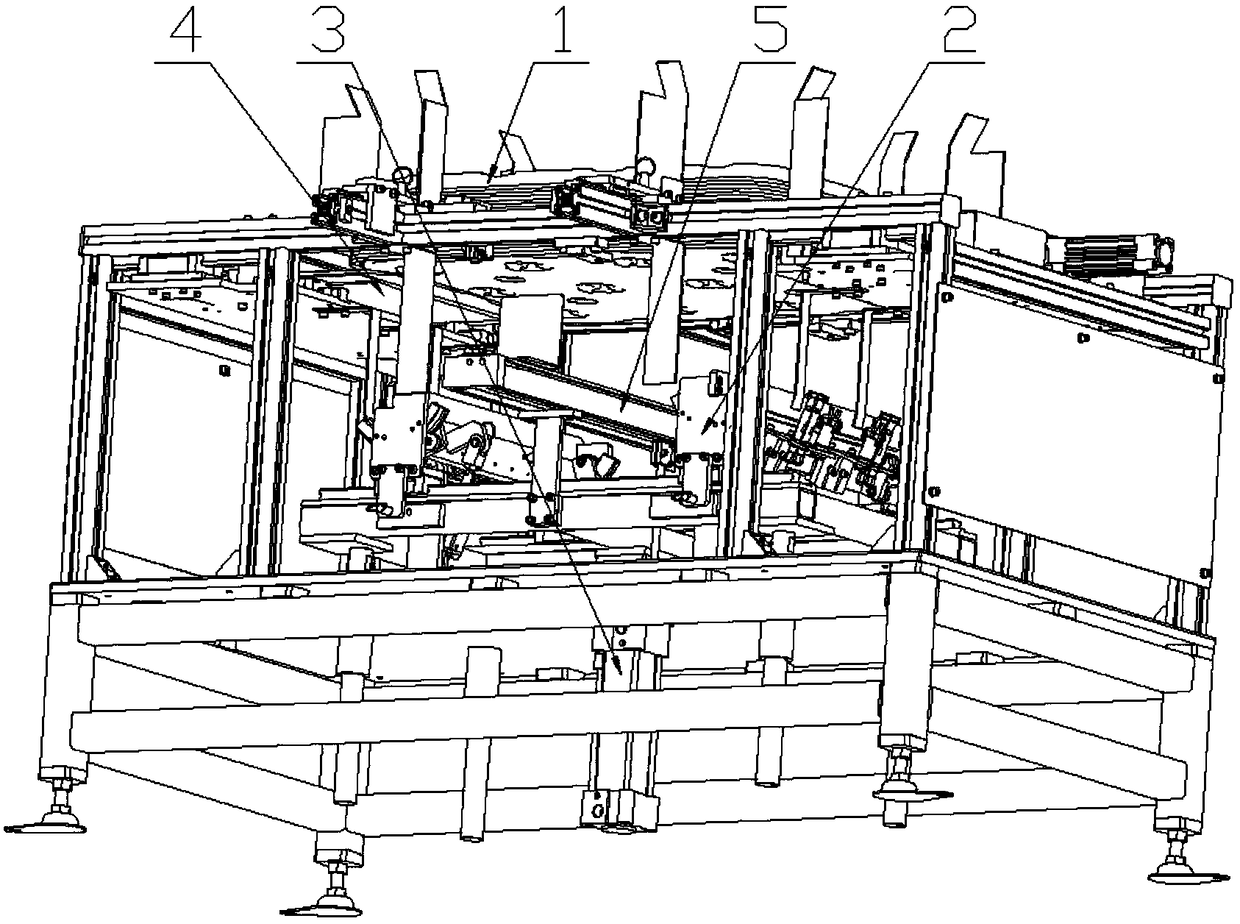

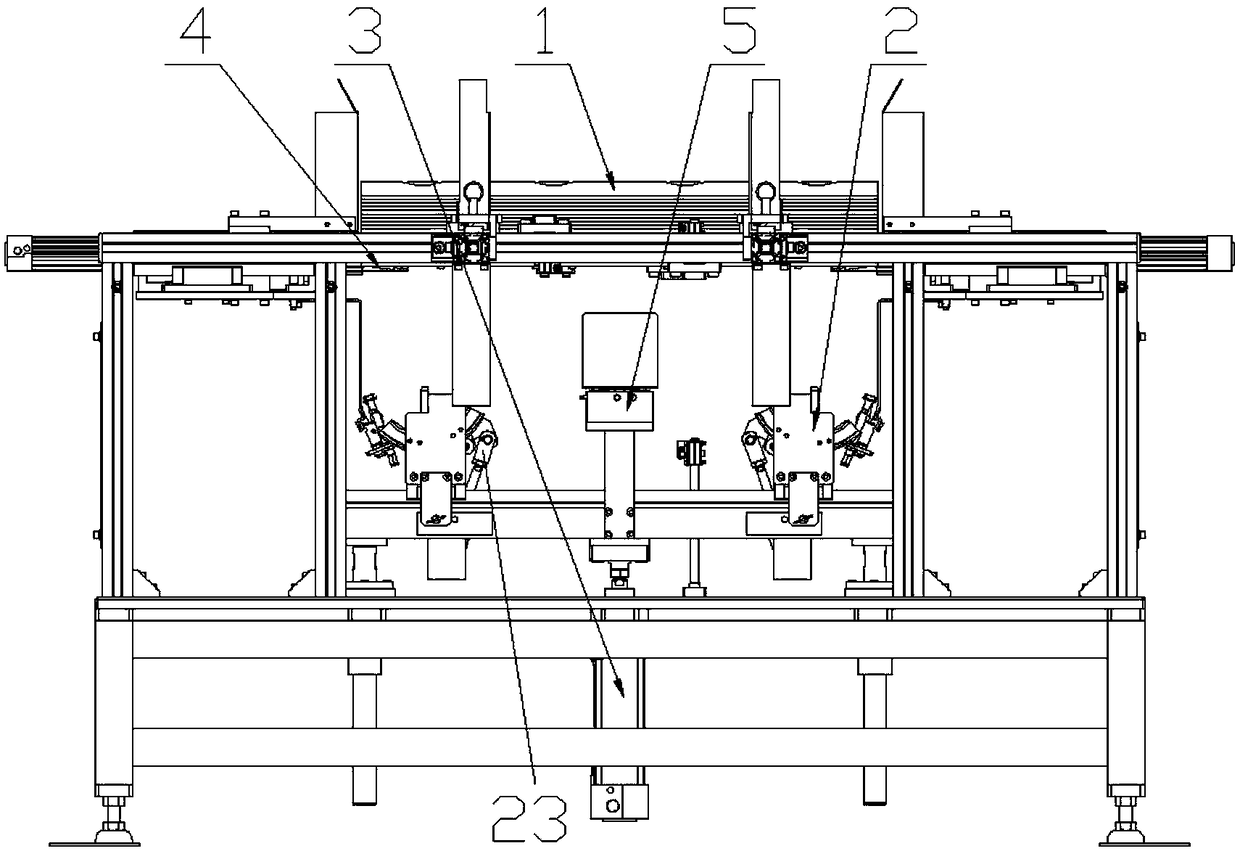

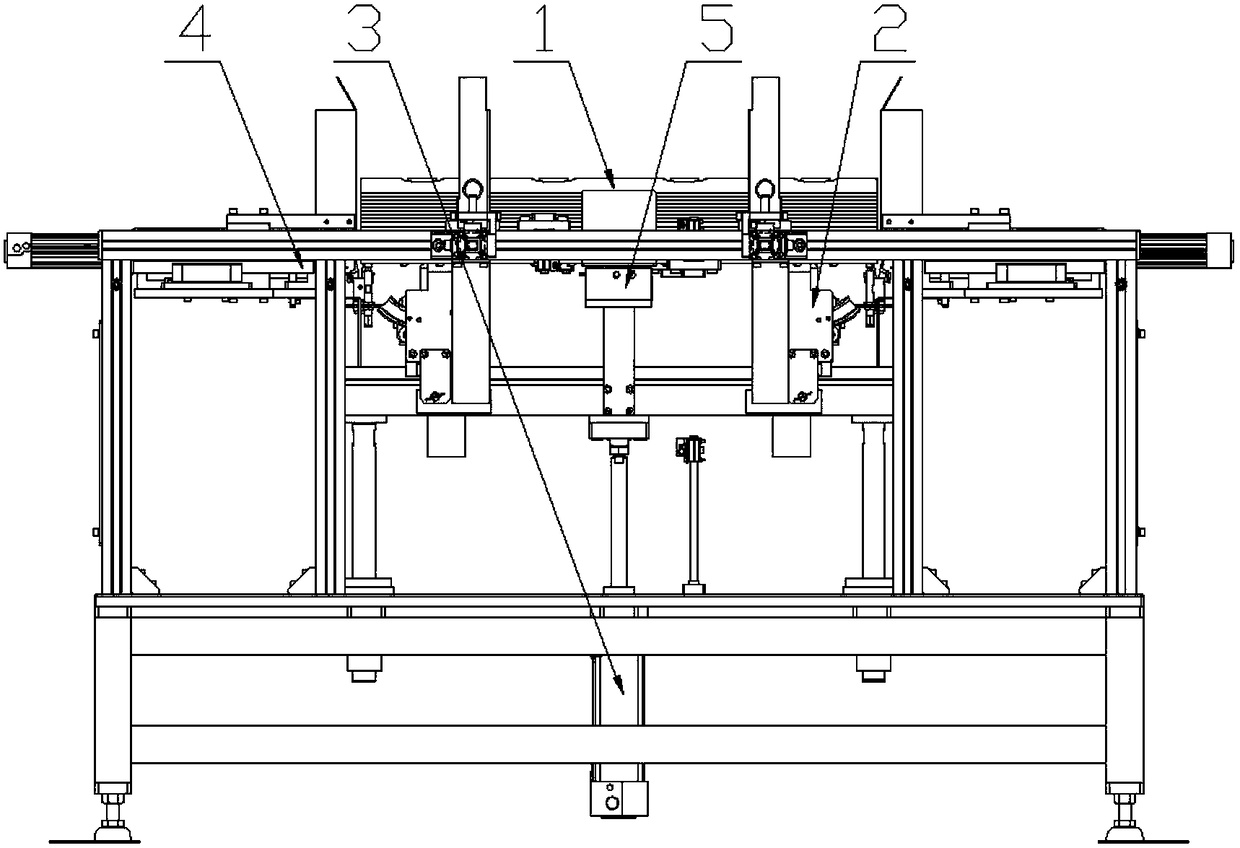

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-9 As shown, the present invention is set on a packaging production line, including a rotary suction mechanism 2, a lifting device 3, a separation pallet assembly 4 and a push-out device 5, wherein the separation pallet assembly 4 and the lifting device 3 are all installed on a bracket The separating pallet assembly 4 is provided with a retractable pallet 21, and a stack of plastic partitions 1 is held by the pallet 21, and the lifting device 3 is provided with a lifting frame 18. Both the rotary suction mechanism 2 and the push-out device 5 are installed on the lift frame 18, wherein the two rotary suction mechanisms 2 are respectively arranged on both sides of the lift frame 18, and the push-out device 5 is arranged in the middle of the lift frame 18. The rotary suction mechanism 2 is provided with a rotatable and swingable swing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com