Thermal magnetic tripping device and circuit breaker thereof

A technology of thermal magnetic tripping and circuit breaker, applied in the direction of protection switch operation/release mechanism, etc., can solve the problem of low bending stability of bimetals, and achieve the effect of improving bending rate, preventing contact, and increasing bending length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

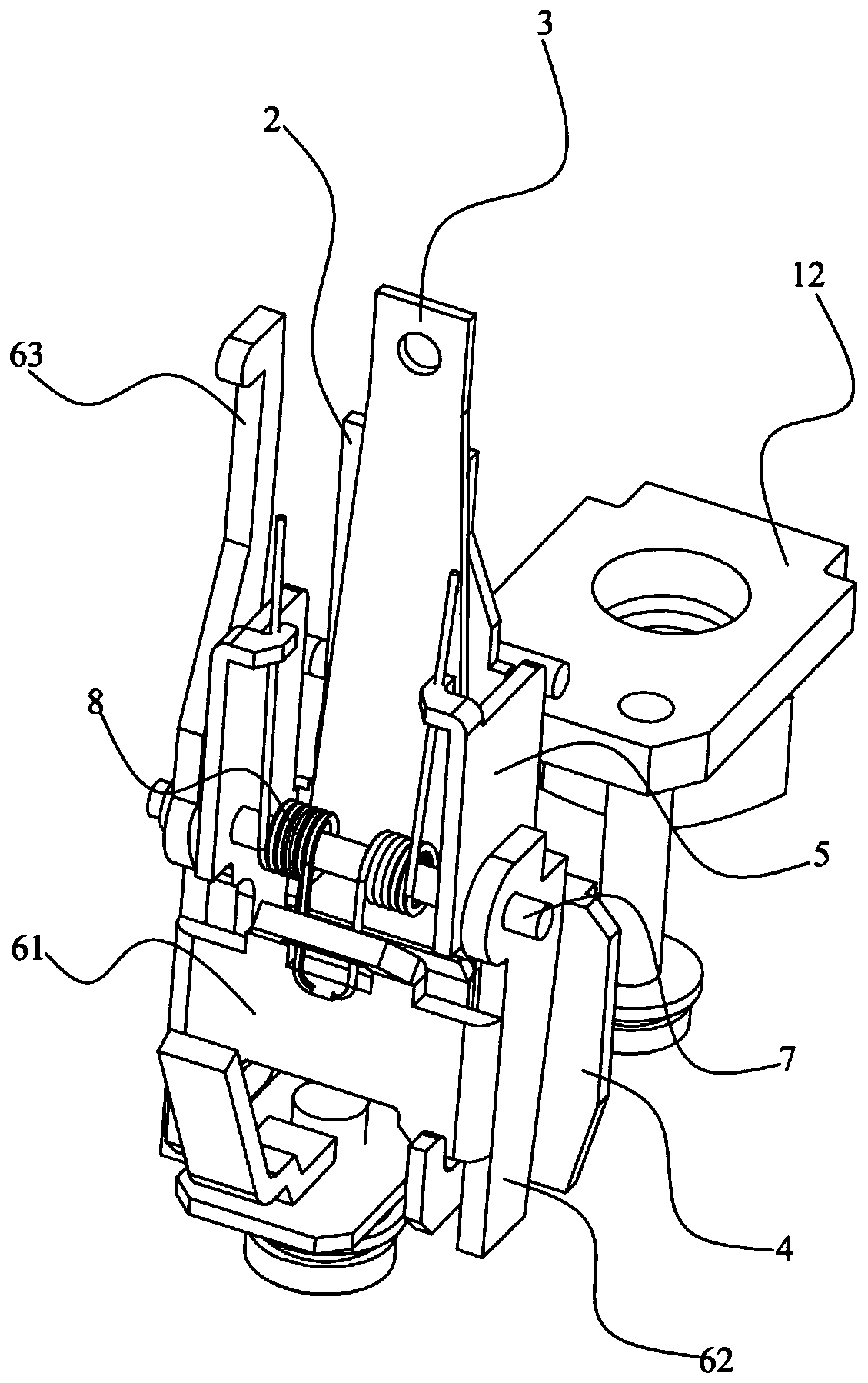

[0054] Such as Figure 1 to Figure 5 A specific implementation of the thermal-magnetic tripping device shown includes:

[0055] Conductor 1.

[0056] The heating element 2 is connected with the conductive member 1 to make the heating element 2 generate heat.

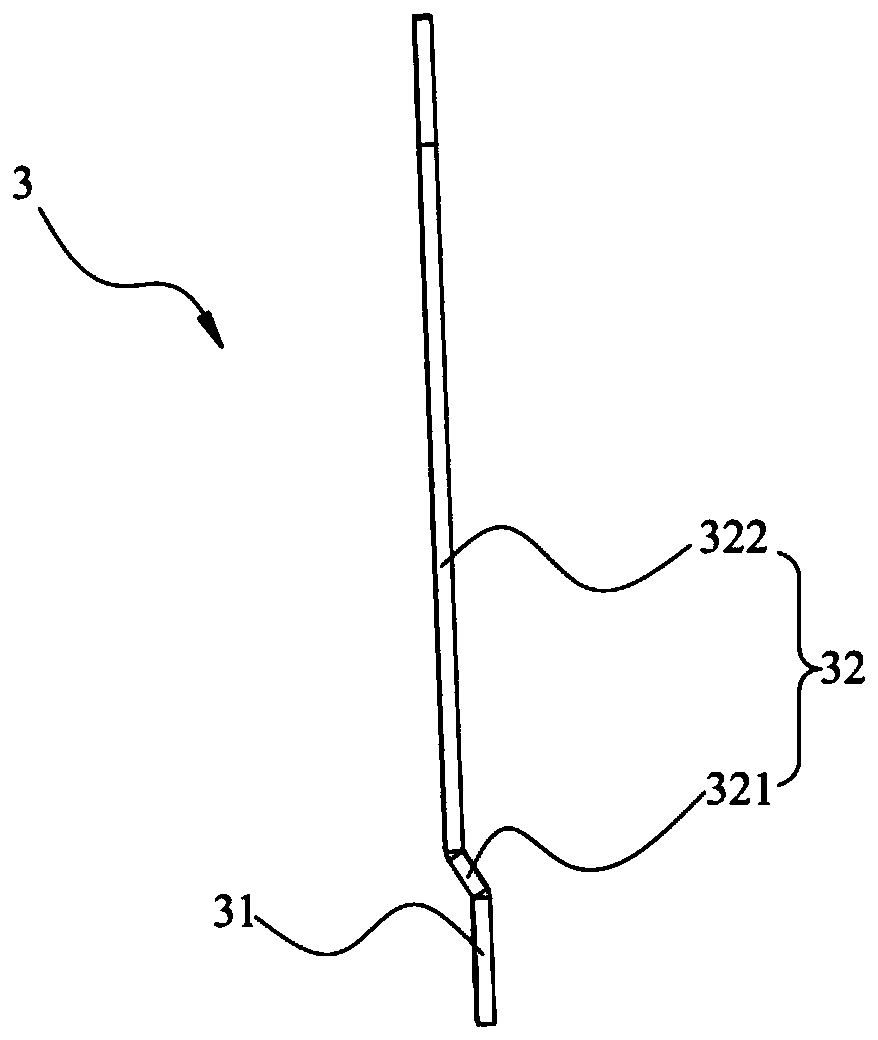

[0057] The bimetal 3 includes a fixed part 31 and a movable part 32 connected to the fixed part 31, the fixed part 31 is fixedly connected to the thermal element 2, and the movable part 32 is arranged opposite to the thermal element 2 The fixed part 31 receives the heat of the heating element 2 to bend and deform the movable part 32, so that the end of the movable part 32 away from the fixed part 31 drives the draw bar 9 of the circuit breaker to rotate.

[0058] The magnetic tripping mechanism is fixedly connected with the thermal element 2 and the bimetal strip 3, and is used to drive the draw bar 9 of the circuit breaker to rotate.

[0059] The thermal-magnetic tripping device above includes a conductive part 1, a ...

Embodiment 2

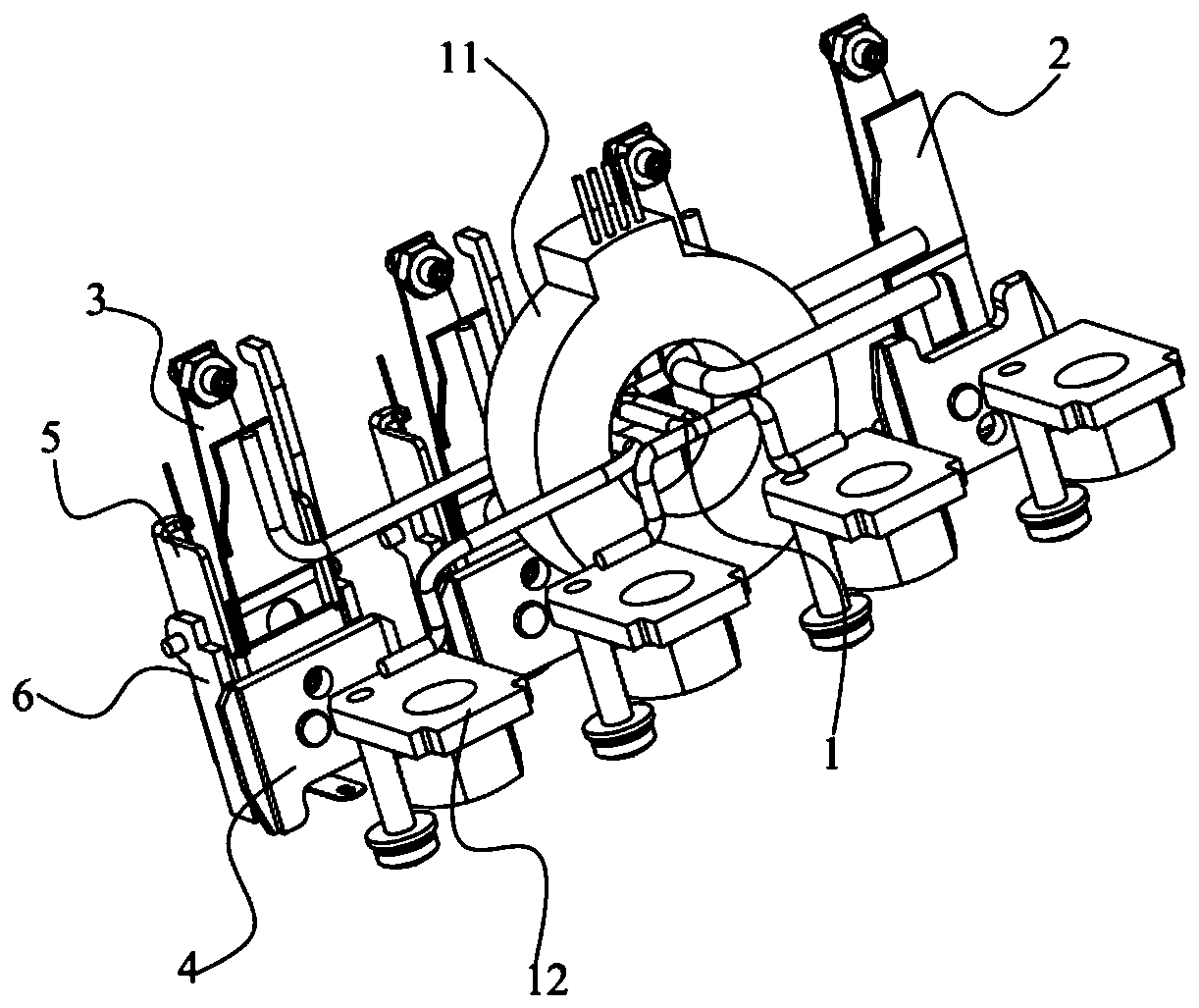

[0082] Such as Figure 1 to Figure 7 A specific implementation of the circuit breaker includes the thermal-magnetic tripping device described in Embodiment 1, which can make the bimetal 3 in the circuit breaker have good bending stability, and then make the thermal-magnetic tripping device The stability is better.

[0083] Such as Image 6 As shown, the circuit breaker also includes a housing 10 and a magnetic ring 11 disposed in the housing 10, the thermal-magnetic tripping device is disposed in the housing 10, and the conductive member 1 is located in the magnetic ring 11, and one end protrudes from the magnetic ring 11 to connect with the connecting plate 12, and the magnetic ring 11 is located between the connecting plate 12 and the static iron core 4.

[0084] In the prior art, the conductive parts in the circuit breaker with low rated current are directly connected to the bimetal, causing the bimetal sheet to heat and bend. This kind of circuit breaker with low rated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com