Method for optimizing tension system of cold continuous rolling unit by taking crack control as target

A technology of cold tandem rolling mills and optimization methods, applied in tension/pressure control, special data processing applications, instruments, etc., can solve the problems that cannot solve the purpose of tension system optimization, etc., so as to increase the economic benefits of enterprises, ensure product quality, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

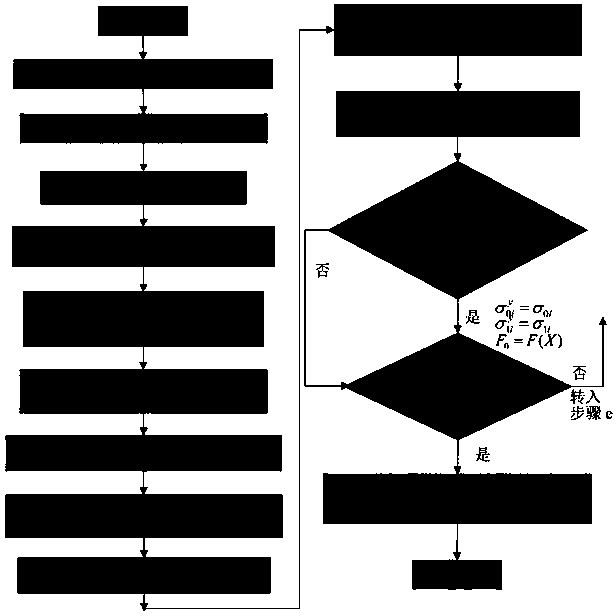

[0034] In order to better understand the above-mentioned technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

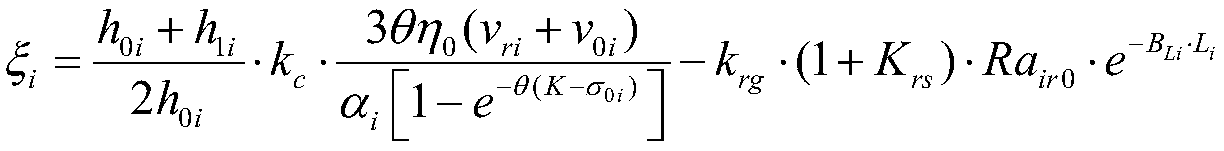

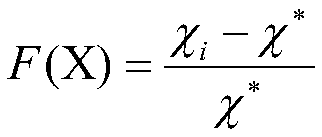

[0035] Such as figure 1 As shown, (a) collect the equipment and process parameters of the cold rolling mill, including: the radius R of the work rolls of each stand i ={1#217.5; 2#217.5; 3#217.5; 4#217.5; 5#217.5} (mm), the surface speed v of each rack roll ri ={1#297; 2#471; 3#684; 4#976; 5#999}(m / min), original roughness Ra of work rolls of each frame ir0 ={1#0.6; 2#0.6; 3#0.6; 4#0.6; 5#0.6} (μm), work roll roughness attenuation coefficient B Li ={1#0.01; 2#0.01; 3#0.01; 4#0.01; 5#0.01}, the rolling kilometers L of the working rolls of each stand after changing rolls i ={1#200; 2#280; 3#300; 4#320, 5#250}(km), wherein, i=1,2,...,n, represents the stand number of the tandem cold rolling mill, n is the total number of racks, the same below;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com