Spiral hoop reinforcement manufacturing machine

A technology of spiral stirrups and manufacturing machines, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve the problems of poor quality, high labor intensity, complicated process, etc., and achieve simple and practical structure and stable dimensions , the unique effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

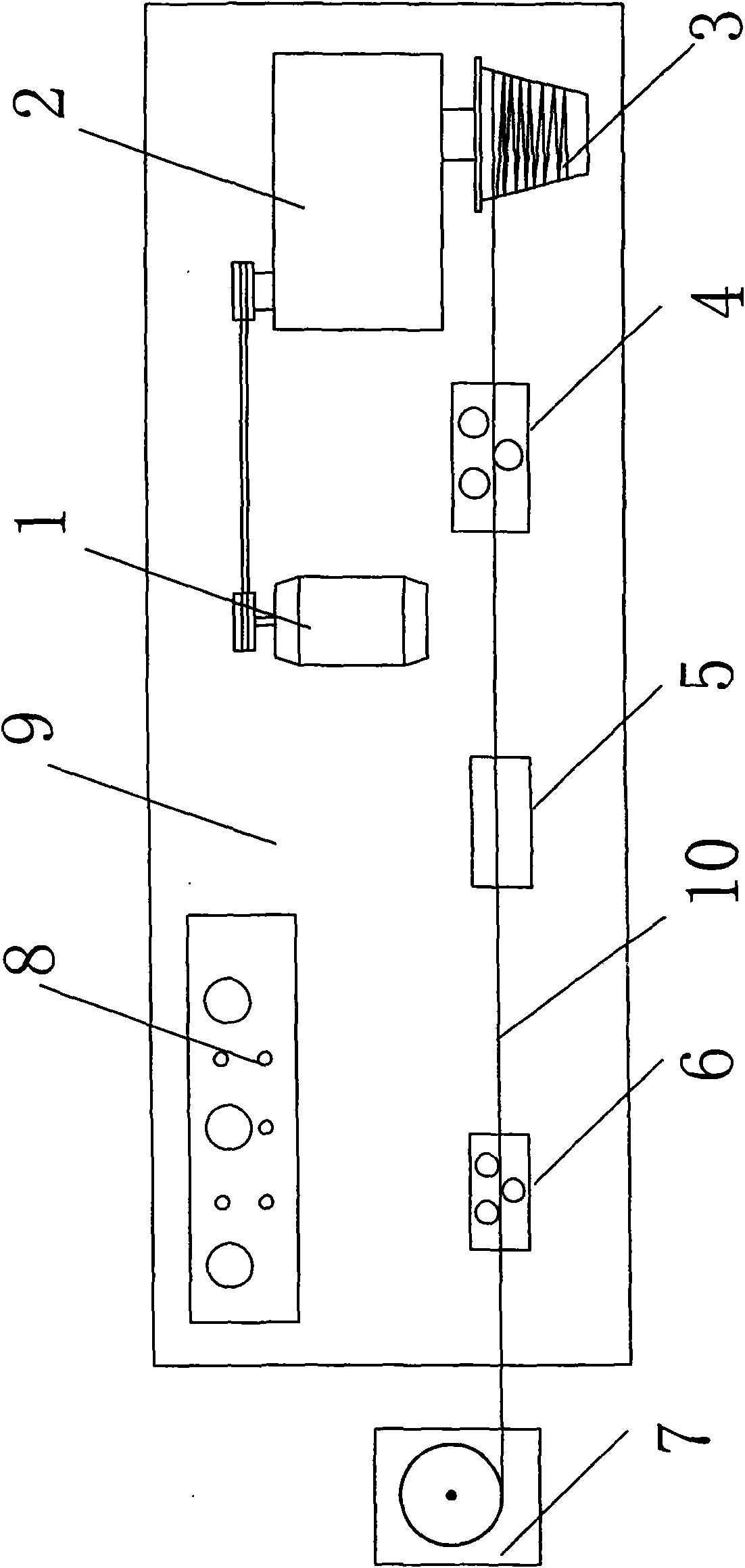

[0009] Such as figure 1 In the spiral stirrup making machine shown, the motor 1, the reducer 2, the forming disc 3, the feed counter 4, the wire puller 5, and the straightener 6 are all installed on the same body 9, and the body 9 is also equipped with a control panel 8, The control panel 8 is connected to the motor control switch. The output shaft of the motor 1 is connected to the reducer 2. The reducer 2 is driven by the motor 1. The low-speed end of the reducer is connected to the forming plate 3. The forming frame with variable size and angle is installed on the forming plate. The round steel bar 10 on the tray 7 is dynamically connected to the forming disc 3 through the straightener 6, the wire puller 5, and the counter 4. The forming disc 3 is driven by the motor 1 and the reducer 2 to rotate, and the steel bar 10 is firstly processed by the wire puller. Wire drawing, while drawing the steel bar 10 is dynamically transmitted to the forming disc 3 for winding, so as to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com