Low-temperature fatigue property characterization and life estimation method

A technology of fatigue performance and characterization, applied in computing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

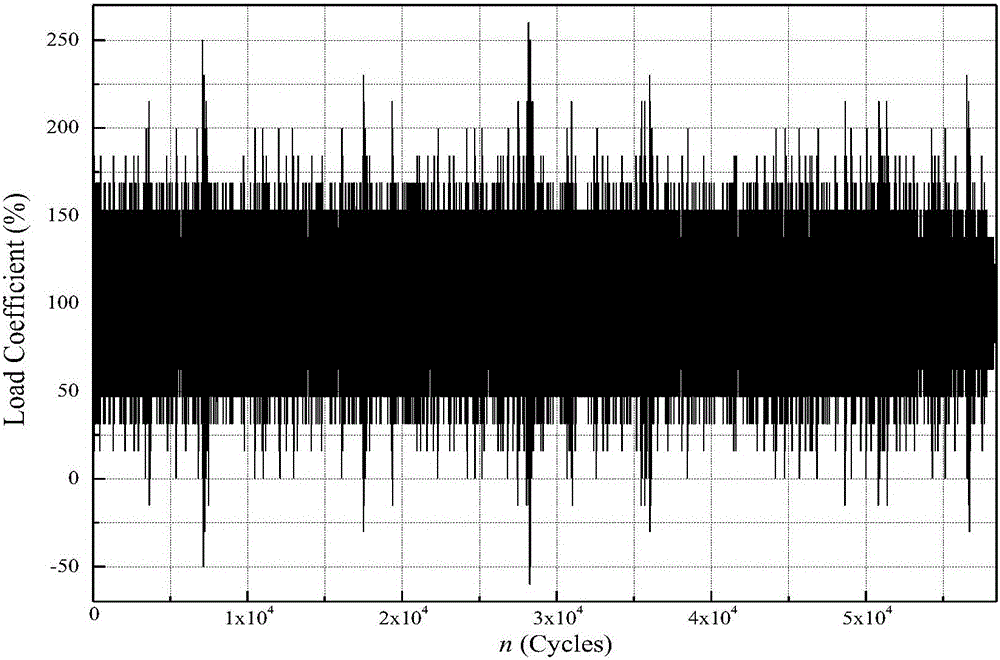

[0069] Figure 4 It is a flowchart of the method of the present invention, and the present invention is implemented in three steps, specifically:

[0070] Step 1. Characterization model of low temperature fatigue performance

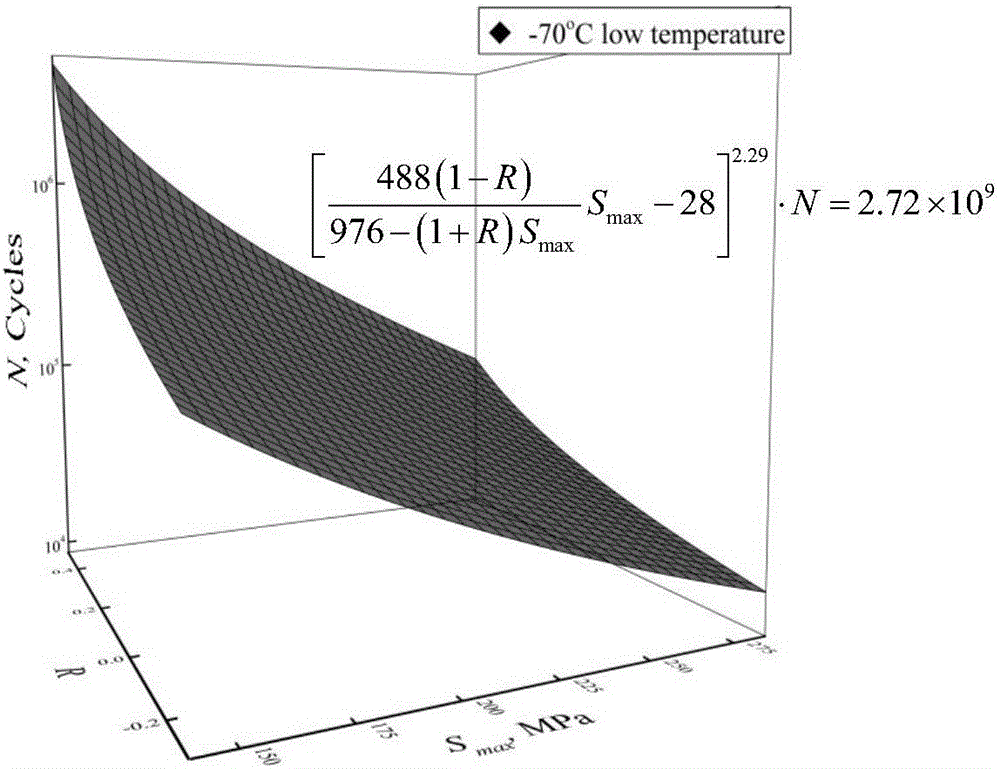

[0071] figure 1 is the loading schematic diagram of the fatigue center notch specimen, according to figure 1 The loading form and standard "Constant Amplitude Axial Fatigue Test Method for Metal Materials" (HB5287-96), the fatigue test is carried out in a low temperature environment. Under a single stress ratio R, the group test method and the lift test method are used to select different maximum fatigue stress S max Loading, the fatigue failure cycle number N of different life ranges is obtained. Record each group of fatigue test results S max and N, and a three-parameter power function empirical formula is used to characterize the fatigue performance under a single stress ratio:

[0072] (S max -S 0 ) m ·N=C(1)

[0073] In the formula, S 0 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com