A method for analyzing fatigue life of steering knuckle

A technology of fatigue life analysis and fatigue life, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of ignoring plastic strain, increasing development cycle and cost, lack of fatigue life analysis methods, etc., to achieve fatigue analysis The result is precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

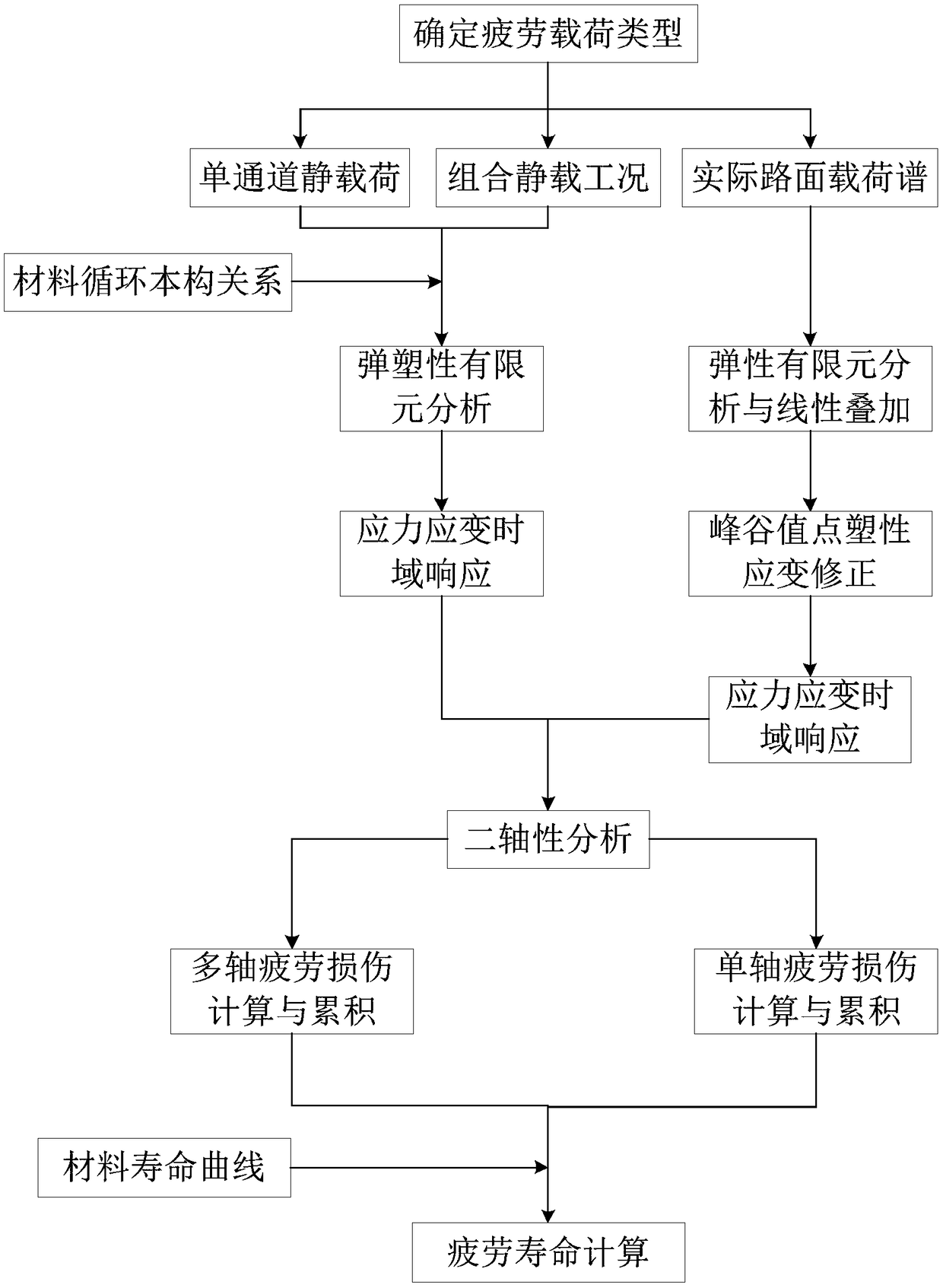

[0044] like figure 1 As shown, in the embodiment of the present invention, a steering knuckle fatigue life analysis method includes the following steps:

[0045] Obtain the fatigue load of the steering knuckle. If it is a combined static load condition, it is necessary to obtain the load of each static load condition. The method is to calculate the contact point of the wheel or the center of the wheel by defining the dynamic load coefficient of the vehicle driving condition. Force, and then obtain the load of each installation point of the steering knuckle by inputting the force of the wheel contact point or the wheel center in the multibody dynamics model.

[0046] As an example, Table 1 shows the loads of the steering knuckle and the control arm installation point under six working conditions. Because the installation point is connected by a spherical joint, there are only three translational force components and no torque.

[0047] Table 1

[0048]

[0049] like figu...

Embodiment 2

[0066] In this embodiment of the present invention, as figure 1 As shown, a steering knuckle fatigue life analysis method includes the following analysis process:

[0067] Obtain the fatigue load of the steering knuckle, if it is the actual road load spectrum, because the actual road load spectrum directly measures the six-component force at the four wheel centers of the car, so the wheel center force needs to be decomposed to obtain the load spectrum of each installation point of the steering knuckle, The method is to establish the vehicle dynamics model in the multi-body dynamics software, take the wheel center force load spectrum as the iterative target, obtain the excitation signal of the virtual vertical wheel cylinder, and use the excitation signal as the input of the dynamics simulation, and then Obtain the load spectrum of each installation point of the steering knuckle, such as the load spectrum obtained in the x direction of the load of the steering knuckle and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com