Transmission system load signal testing, analyzing and processing method of wheel-type loader

A wheel loader and load signal technology, which is applied in the test of machine gear/transmission mechanism, the test of machine/structural components, mechanically driven excavator/dredger, etc., can solve the problem of complex load test parts and difficult to achieve and other problems to achieve the effect of facilitating the analysis of test results, shortening the test and development cycle, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

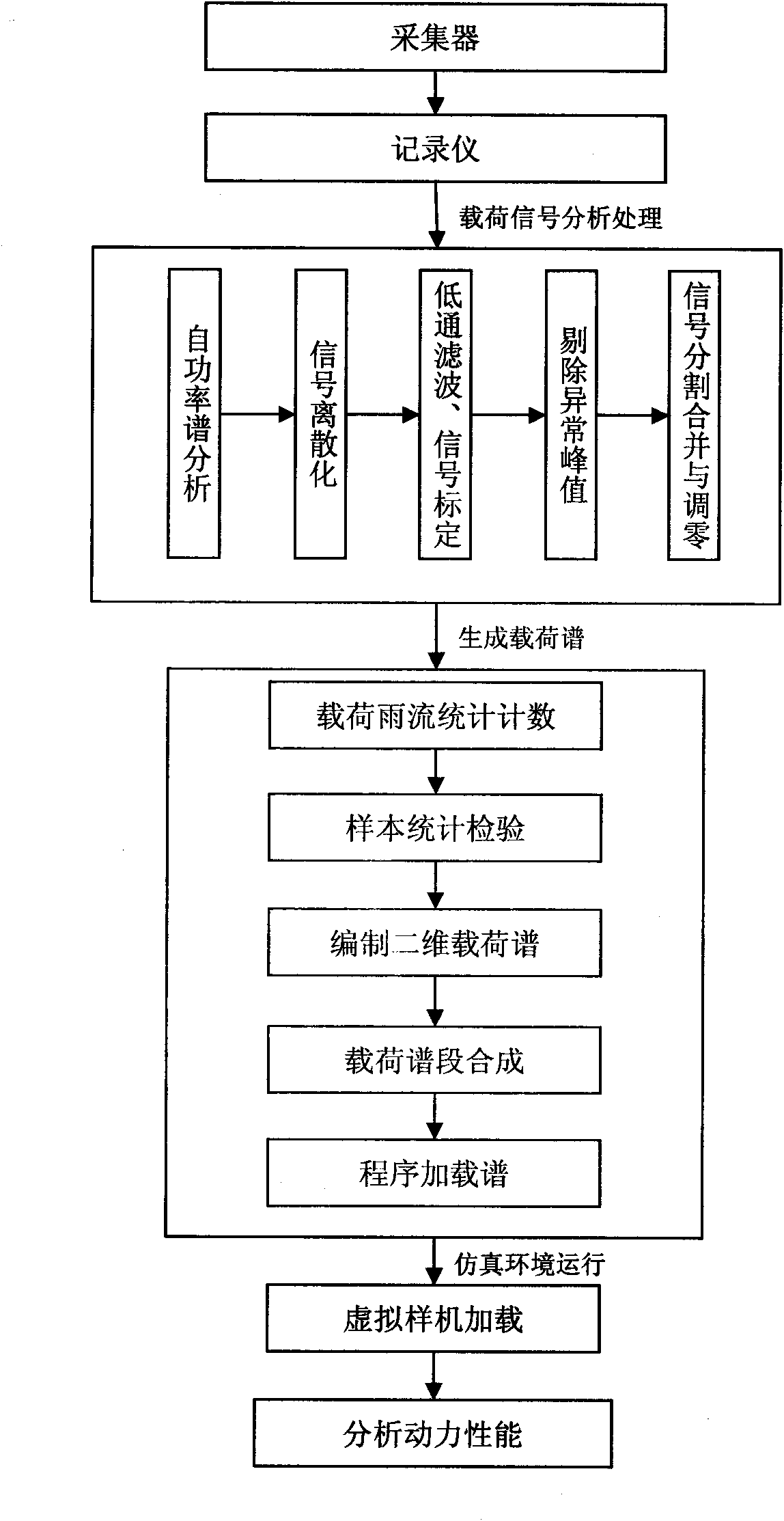

[0024] Example: such as figure 1 As shown, the wheel loader drive train load signal test and analysis process is carried out according to the following steps:

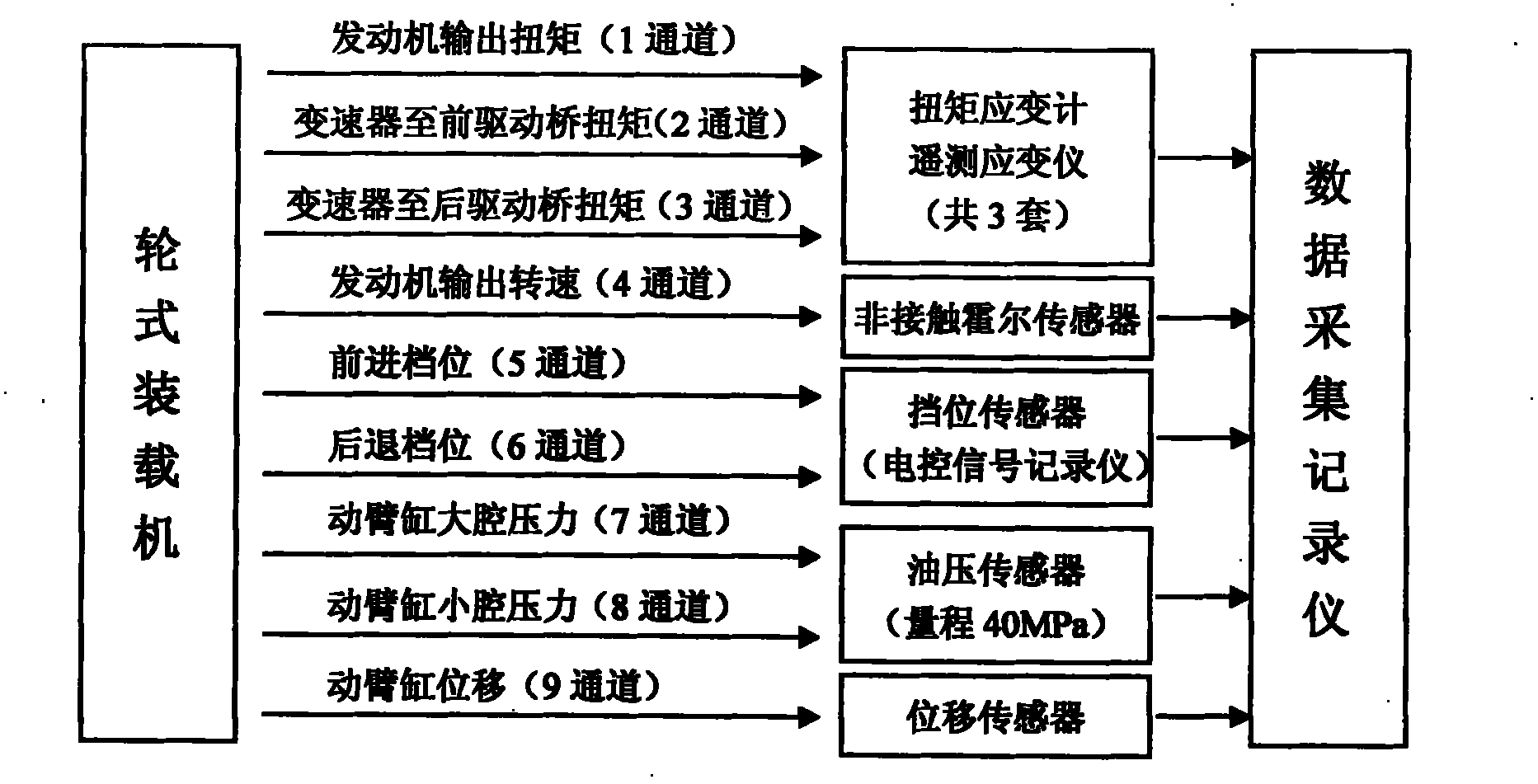

[0025] 1. Test the load signal of the wheel loader: according to the output torque of the engine, the torque output from the gearbox to the front drive axle, the torque output from the gearbox to the rear drive axle, the speed of the intermediate shaft of the loader, the forward gear, the reverse gear, the boom Cylinder large chamber pressure, boom cylinder small chamber pressure, boom cylinder displacement, a total of 9 test items determine the 1-9 channels of the test, and the load signal test of the wheel loader drive train is carried out as follows:

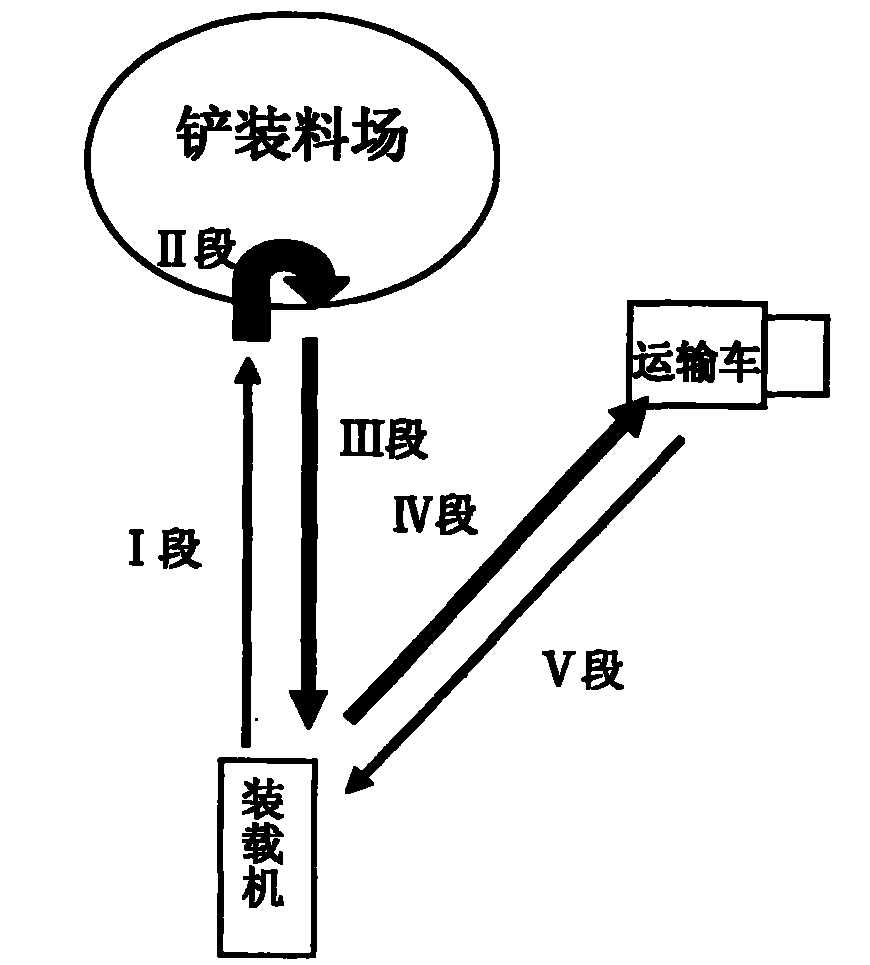

[0026] (1) Select the test prototype and determine the test conditions; select the ZL50 wheel loader, and require good working performance; prepare raw soil, stonework, and loose soil as a typical loading and unloading yard, and require sufficient materials; determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com