Road load test method and system

A technology of load testing and road load spectrum, which is applied in the field of manufacturing technology, can solve problems such as the inability to effectively improve the fatigue durability of the vehicle body and the inability to accurately predict the fatigue life of the vehicle body, and achieve the effect of improving the fatigue durability and accurate prediction of the vehicle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

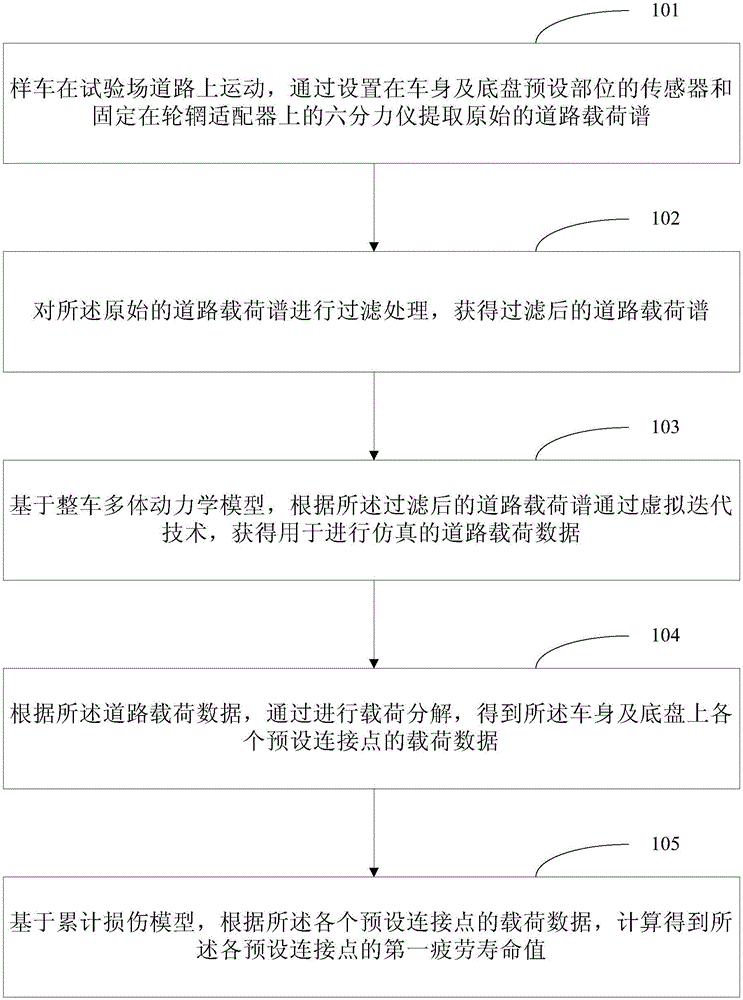

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 For the flow chart of the first embodiment of the road load testing method of the present invention, please refer to figure 1 , the invention provides a road load testing method, comprising:

[0024] Step 101, the prototype vehicle moves on the road of the proving ground, and extracts the original road load spectrum through the sensors arranged at the preset positions of the body and chassis and the sextant fixed on the rim adapter;

[0025] Specifically, the original road load spectrum extracted by the sextant includes the force and torque of the sample car in the X, Y, and Z directions on roads with different strengths, where the X direction is the direction parallel to the longitudinal axis of the vehicle body, and the Y direction is the direction parallel to the longitudinal axis of the vehicle body. A direction is a direction parallel to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com