Method for predicting fatigue life of horizontal semi-adjusting axial flow pump impeller blade fixing bolt

A technology for fixing bolts and impeller blades, which is applied in the field of fatigue life prediction of impeller blade fixing bolts of horizontal semi-adjustable axial flow pumps, and can solve the problems of easy fracture of blade fixing bolts and low fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0175] Below in conjunction with embodiment, the present invention is further invented:

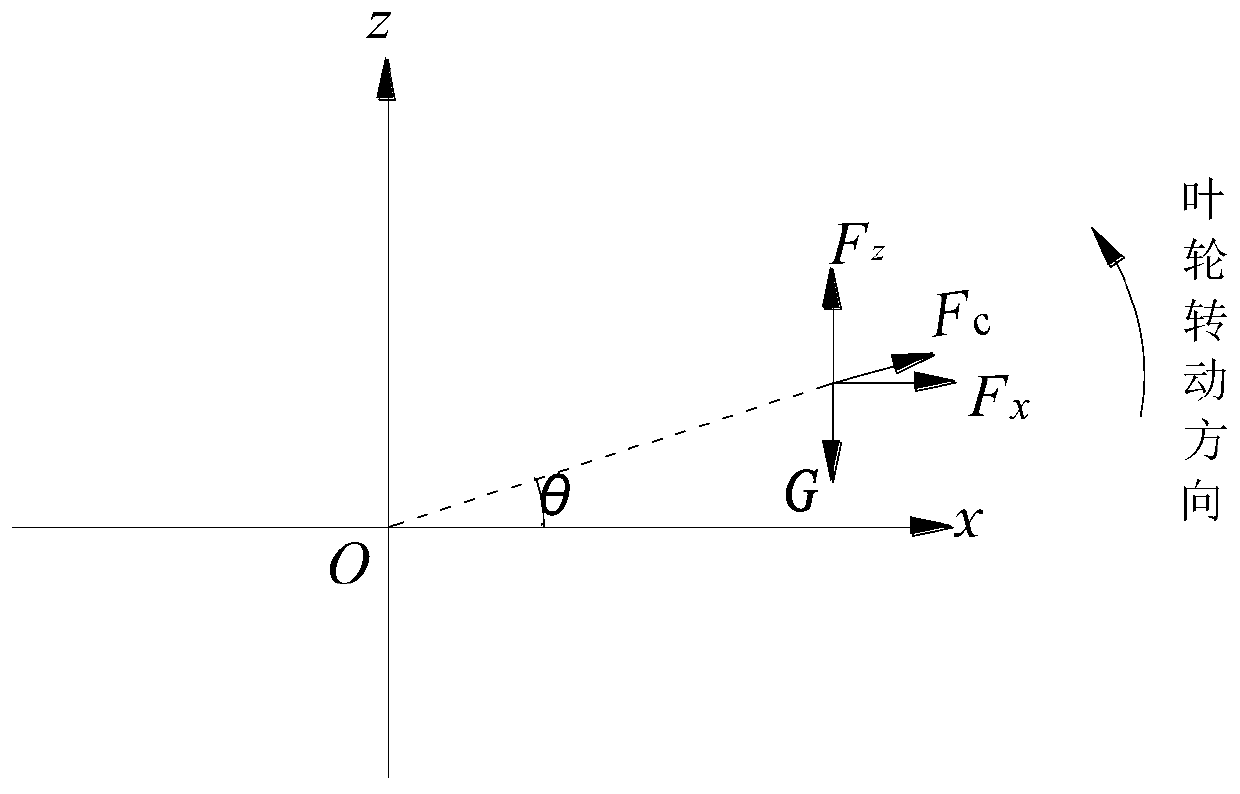

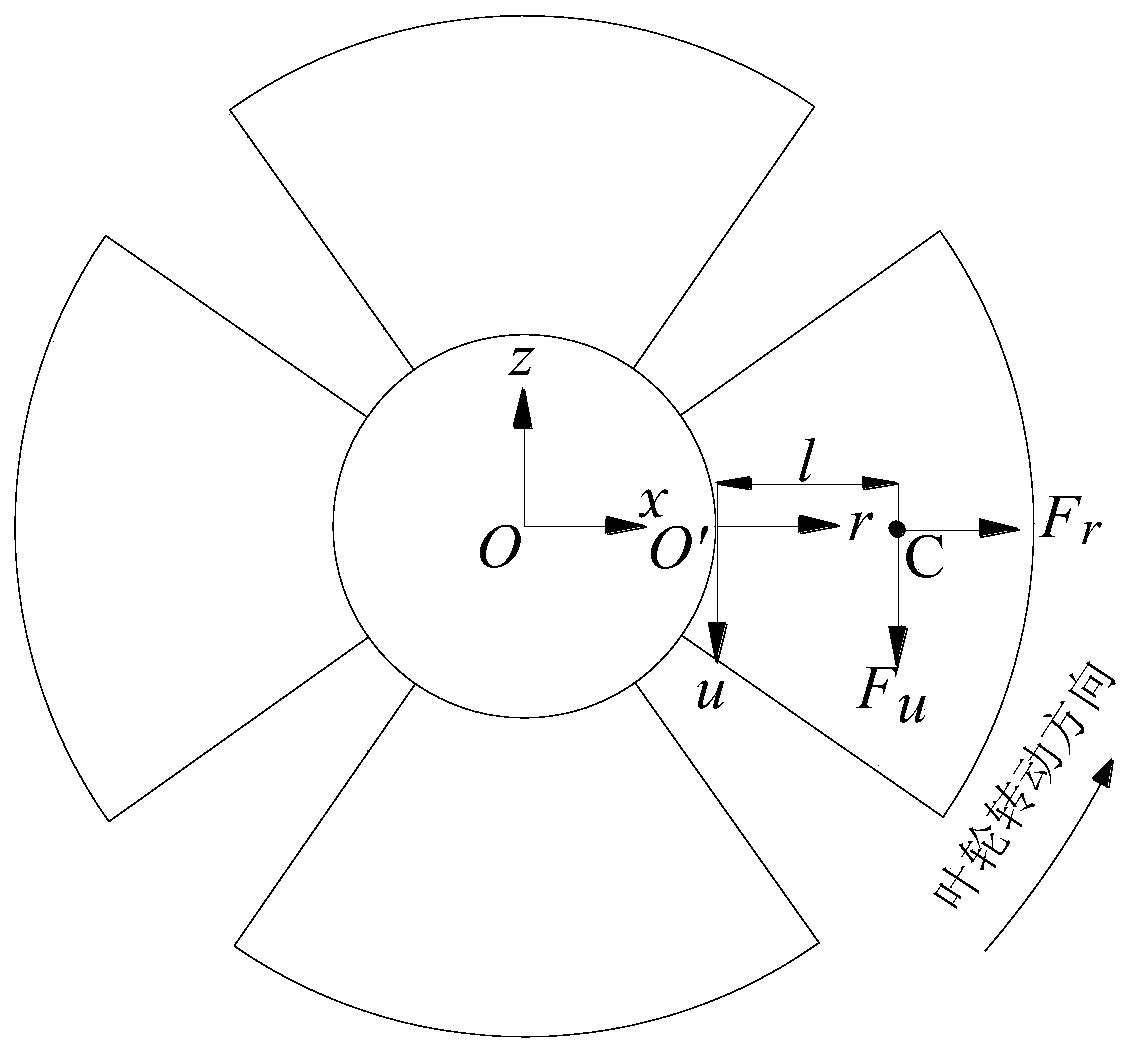

[0176] A horizontal semi-regulated axial flow pump in a pumping station, with an impeller diameter of 1.45m, a head of 1m, and a flow rate of 5m 3 / s, the speed is 218r / min, the number of blades is 4, and the weight of a single blade is 86.2kg. The stiffness coefficients of the pressure plate, hub, flange and bolts are shown in Table 7; the blades are made of stainless steel 2Cr13, and their material properties are shown in Table 8.

[0177] Table 7 Stiffness coefficient of pressure plate, hub, flange and bolt

[0178]

[0179] Table 8 Material properties of 2Cr13

[0180]

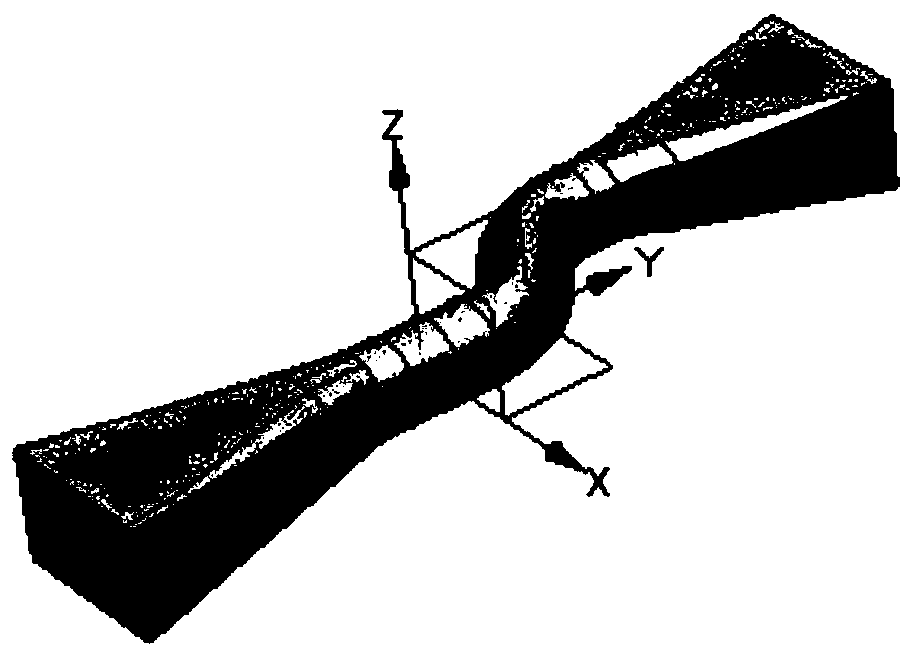

[0181] A. Three-dimensional modeling and grid division of the flow field calculation area of the horizontal semi-regulated axial flow pump;

[0182] The three-dimensional modeling of the calculation area of the pump flow field is carried out through UG, including the water inlet pipe, guide vane, and outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com