A method for predicting the fatigue life of water pump blades and determining the optimal distance between them and guide vanes

A determination method and technology of fatigue life, applied in pump control, non-variable capacity pump, design optimization/simulation, etc., can solve the problems affecting the normal operation of the pump, fatigue fracture, low blade life, etc., to improve the design and operation method , Improve fatigue durability and ensure the effect of pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0077] A large vertical axial flow pump in a pumping station, impeller diameter 1640mm, impeller hub diameter 820mm, blade design angle 0°, speed 250r / min, pump device design head 6m, design flow rate 10.6m 3 / s, blade angle adjustment range: -4°~+6°. The blade is made of stainless steel ZG1Cr18Ni9Ti, and its material properties are shown in Table 7:

[0078] The material property of table 7 embodiment blade

[0079]

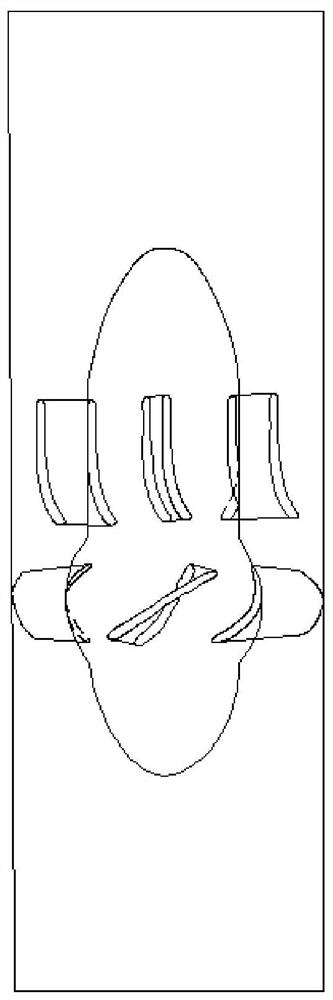

[0080] The structure of the water pump impeller and guide vane, as well as the performance curve of the pump device are known.

[0081] Determination of the dangerous section and dangerous point of the fatigue fracture of the water pump blade:

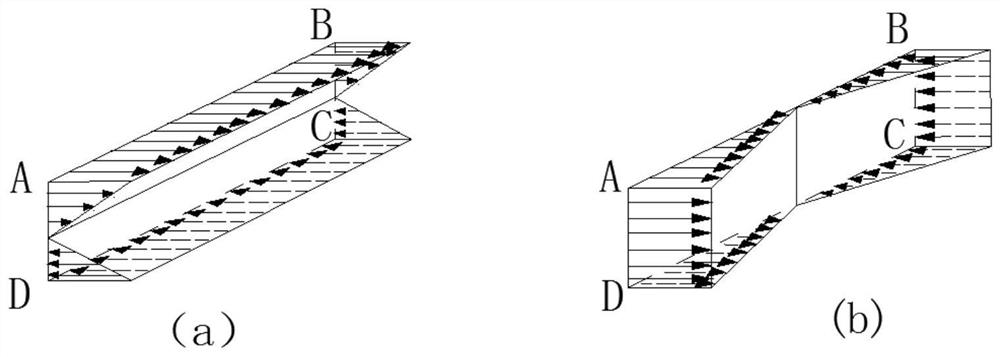

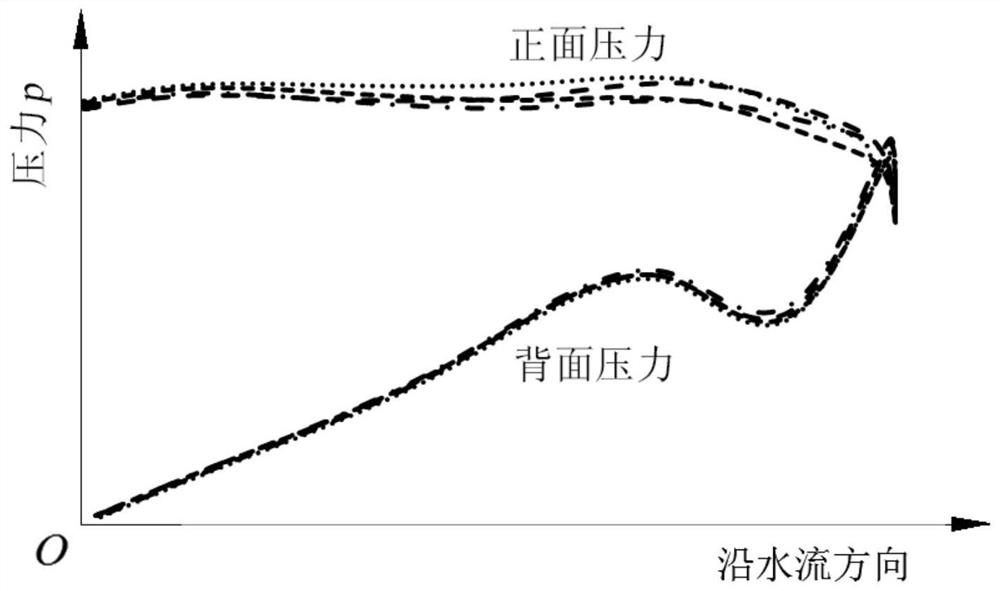

[0082] Such as figure 1 As shown, from the perspective of static force, point A on the inlet side of the upper edge of the connection between the root section of the blade and the hub is superimp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com