A Large Bearing Test Bench with Static Pressure Loading and Closed Structure

A technology of bearing test and test bench, which is applied in the direction of mechanical bearing test, etc., can solve the problems that it is difficult to meet the test requirements of slewing ring bearings, the specific performance of a single bearing cannot be detected, and the detection accuracy is low, so as to achieve high rigidity, low cost, The effect of reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

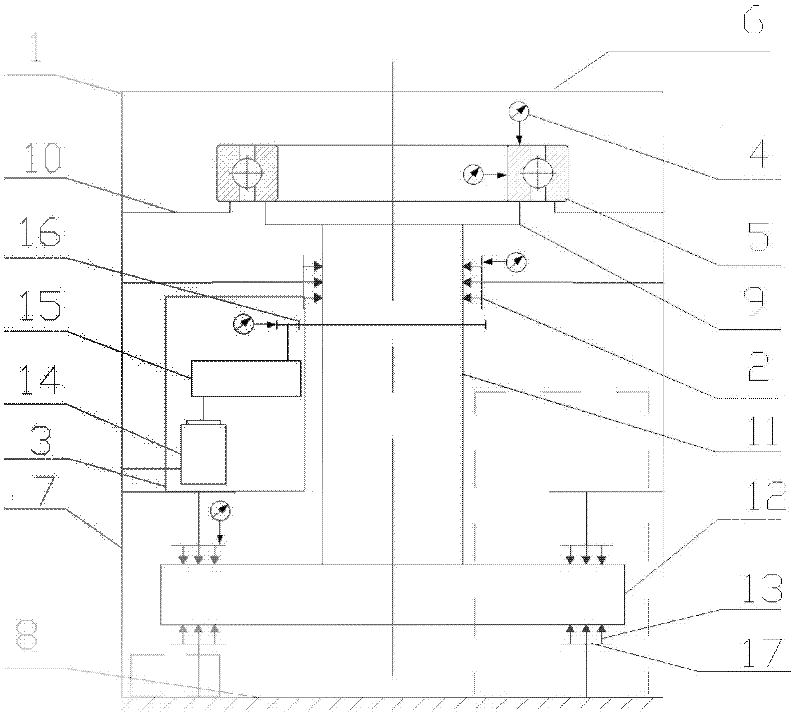

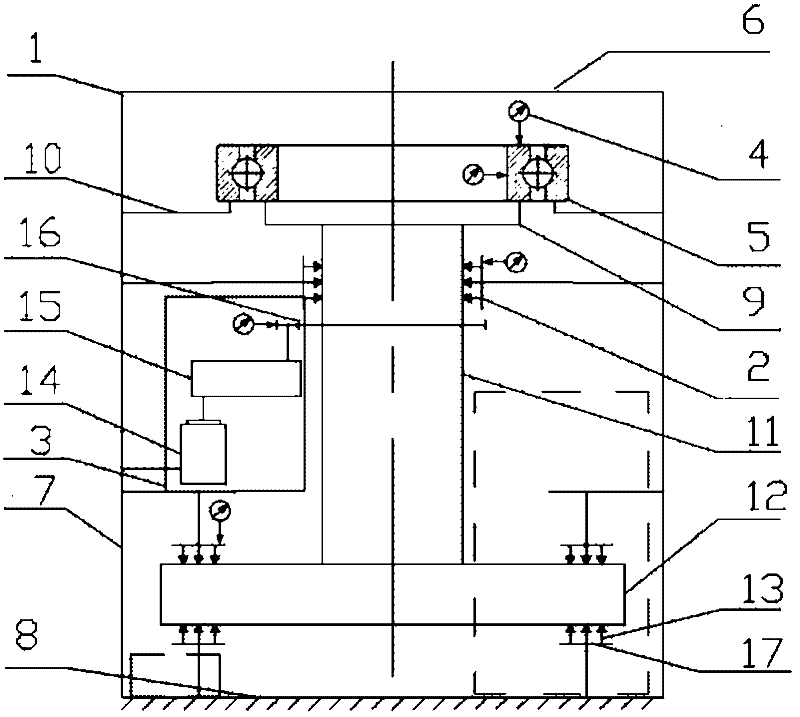

[0020] Such as figure 1 Shown is the closed structure of the vertical bearing of the present invention: the bearing test bench of the present invention is composed of four parts: a closed mechanical structure 1, a static pressure loading system 2, a drive system 3, and a measurement and control system 4.

[0021] Closed mechanical structure 1 is formed closed mechanical structure by parts such as test bearing 5 and test bench end cover 6 and connecting parts, column 7, base 8; The inner ring transition plate 9 and the outer ring transition plate 10 connected to the test bearing are replacement components. For test bearings of different models and installation types, the inner and outer ring transition plates 9, 10 are connected to the top end cover 6 and the loading plate 12. The closed mechanical structure is set on the top of the bearing test bench, and the test bearing can be easily installed by hoisting.

[0022] The static pressure loading system includes a floating test...

Embodiment 2

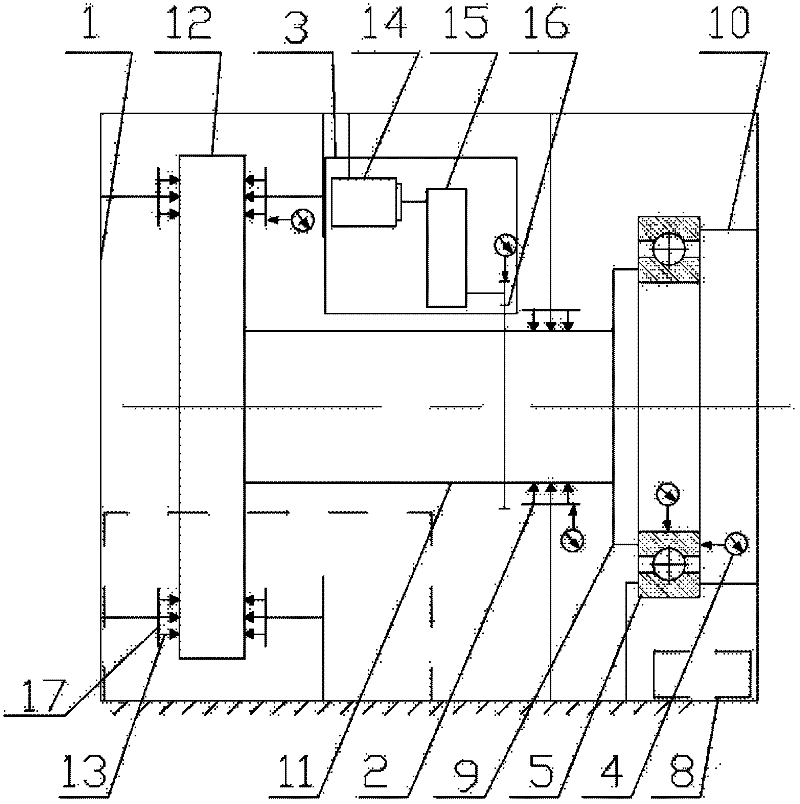

[0026] Such as figure 2 As shown, it is a horizontal closed structure of the present invention, which is basically the same as that in Example 1, wherein the test bearing 5 is installed vertically on the left or right end of the bearing test bench, and the axis of the test bearing is in the horizontal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com